Highlights

Highlights

Benefits

- Provides an alternative to traditional cementing operations for plugging and abandonment and specialty applications

- Minimizes equipment requirements and resources to store and pump the slurry

- Enables modifications to slurry density with microspheres or weighting agents

Applications

- Remote, offshore, and unique wellsite locations

- Plug and abandonment operations

- Medium- to high-temperature wells

Overview

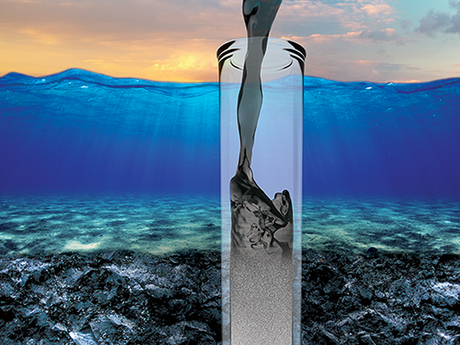

Our patented Liquid Stone™ liquid cement system is a storable, premixed cement slurry that can be kept on site in the liquid state for a period of several days or weeks before use. When ready to pump and set, a liquid activator reinitiates chemical hydration just prior to pumping, which creates a density-controlled pozzolan/Portland cement slurry.

Specific slurry characteristics can be developed with additives. Precise density control is achieved by adding predetermined proportions of a liquid concentrate with mix water. This simplifies primary cementing of major casing strings, whether you are using a single slurry or multiple lead and tail slurries of different densities. The Liquid Stone cement system is also ideal for coiled tubing squeezes, abandonment plugs, slimhole applications and other cementing operation.