Highlights

Benefits

- Safe, reliable and adaptable

- Reduces installation time

- Reduces TOTEX

- Solves a number of technical challenges such as rough seabed topography, dynamic riser in shallow water, slugging

Applications

- Riser, flow & Jumper

- Shallow and ultra deepwaters

- Challenging fluids such as high H2S and even pure dense CO2 at high pressures

- High temperatures

Overview

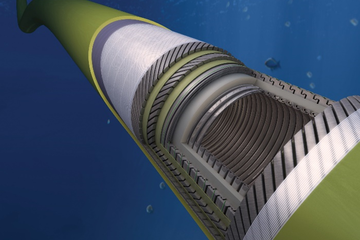

Flexible pipe systems from Baker Hughes deliver reliable, robust production solutions for the life of the field. We develop and deliver flexible pipe risers, jumpers, flowlines, and fluid transfer lines that push past the operational boundaries of their carbon steel counterparts.

Simplifying layouts and mitigating risks

Flexible pipe can simplify your field layouts by connecting directly to subsea equipment, often eliminating the need for pipeline end terminations (PLET) and jumpers.

Because efficient, effective field layout is a critical element in advancing first oil or gas, we have a dedicated team with in-depth experience in pipe design, manufacturing, and installation to help guide you on the decision-making process.

Faster installation and better execution certainty

As flexible pipes are manufactured onshore and come ready to install, they significantly minimize the need for offshore welding so you can install them much more quickly - up to 20 times faster depending on the method.

Greater fleet availability for the installation of flexibles also contributes to helping you with faster deployment and better execution certainty.

Reliable connectivity in a durable design

As offshore and subsea developments move into deeper waters and more challenging environments, you need to be confident in the durability of your equipment. Our flexible pipes are designed to ensure reliable connections and optimal flow - even under high pressures, extreme temperatures and the most corrosive environments.

Versatile and reusable solutions improve cost-effectiveness

Flexible pipes can be recovered and redeployed several times to be used in other fields or additional wells providing you with a more sustainable, cost-effective solution for your piping needs.

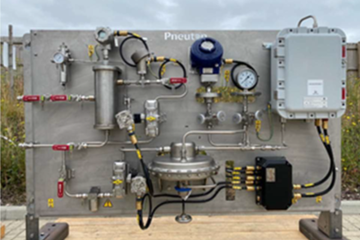

Ensuring pipe health and integrity

For added assurance of structural integrity, our advanced monitoring systems look for damage to the outer sheath layer. Our systems also detect loss of integrity of the tensile armor wires. Detecting those warnings early on help you react quickly—before defects become larger and more expensive repair jobs.

Visit flexible pipes integrity management system page to identify new solutions.

Contact your Baker Hughes representative to learn how our flexible pipe systems can boost your subsea productivity at minimal costs and risks.