Highlights

Benefits

- Drill efficiently in longer, uninterrupted runs

- Reduce drilling cost-per-foot in any application

- Deliver smoother wellbores for improved completions operations

Applications

- Extended-reach and directional drilling applications

- Deepwater and HP/HT well environments

- Shale wells

- Geothermal wells

Overview

Don’t let an inferior drill bit slow you down and drive up drilling costs on your way to target depth (TD). Drill bits from Baker Hughes deliver reliable, efficient drilling solutions to let you stay in the hole longer—with fewer trips and at a lower cost-per-foot.

Working with our drill bit specialists, you’ll access a wealth of knowledge and more than 100 years of drill bit design and application experience that no other bit manufacturer can match.

Proven bit solutions for any downhole environment

When you choose a Baker Hughes drill bit, you’re assured the right bit for your application—from onshore extended-reach wells and deepwater wells to high-pressure/high-temperature (HP/HT) and geothermal wells requiring robust rock destruction solutions.

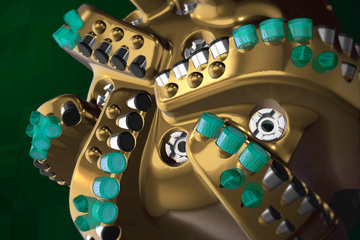

- Our innovative polycrystalline diamond compact (PDC) drill bit technology offers improved cutter durability, enhanced drilling efficiency, and higher rates of penetration (ROPs) in hard, abrasive, and interbedded formations. Our family of PDC bits delivers reliable drilling performance, superior directional control, and high build rates in the transition from a well’s vertical to lateral section.

- Hybrid drill bits combine the rock-crushing strength and stability of roller cones and the continuous shearing action of diamond bits into efficient designs that increase ROP, improve cuttings removal, and withstand highly interbedded formations.

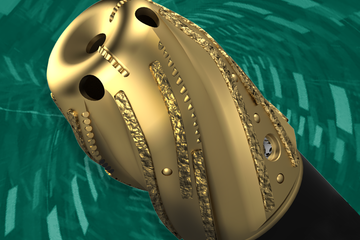

- Adaptive drill bits adjust to different hole conditions, including rock strength changes or stringers. With the unique ability to adjust the depth-of-cut control downhole, our adaptive bits optimize drilling efficiency for any loading condition.

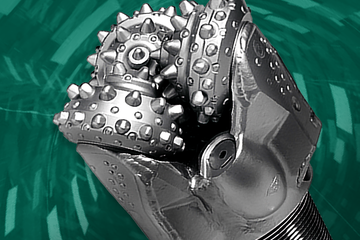

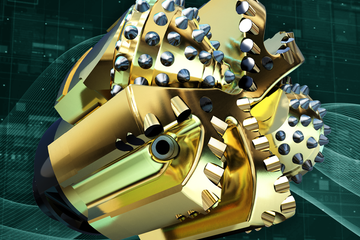

- Our proven roller cone and tricone drill bits are designed for superior drilling performance at higher ROPs with minimal nonproductive time. With designs that combine tungsten carbide inserts, improved hydraulics for bit and hole cleaning, and customized cutter layouts, you’re assured faster drilling rates and longer bit life.

- Our complete line of geothermal drill bits includes proprietary tricone, PDC, and hybrid drill bit designs so that our application engineers can select the optimal bit to deliver superior performance in a specific geothermal formation and address the most-demanding drilling challenges.

- Specialty drill bits reduce drilling costs by successfully reaching TD on the first attempt. The technology reduces the risks associated with problematic wells—including rubble zones, lost-circulation zones, ledges and doglegs, depleted reservoirs, and underground blowouts—while minimizing HSE risks related to tripping in and out of the well.

Advancing bit performance with ongoing design improvements

As your drilling challenges evolve and expand, we’re committed to developing new drill bit solutions to keep pace. Our cross-functional design teams use the latest modeling tools and engineering software to evaluate your specific challenges, design custom solutions, and evaluate performance in proprietary testing labs. This work extends to developing and designing innovative shaped-cutter technologies that optimize cutting rates in hard formations and help the bit stay cool and effective in the hottest downhole conditions.

Contact your Baker Hughes representative to learn how our drill bit solutions can optimize your drilling program.