As global leader in NDT software, Waygate Technologies offers a broad portfolio of integrated and standalone solutions so you can make critical decisions with greater confidence. Our tools are designed to help you make the most of your NDT equipment for smarter, faster, and safer inspections.

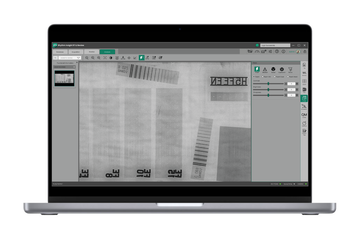

With inspection workflow optimization software, you can maximize the power of your NDT equipment, and your employees.

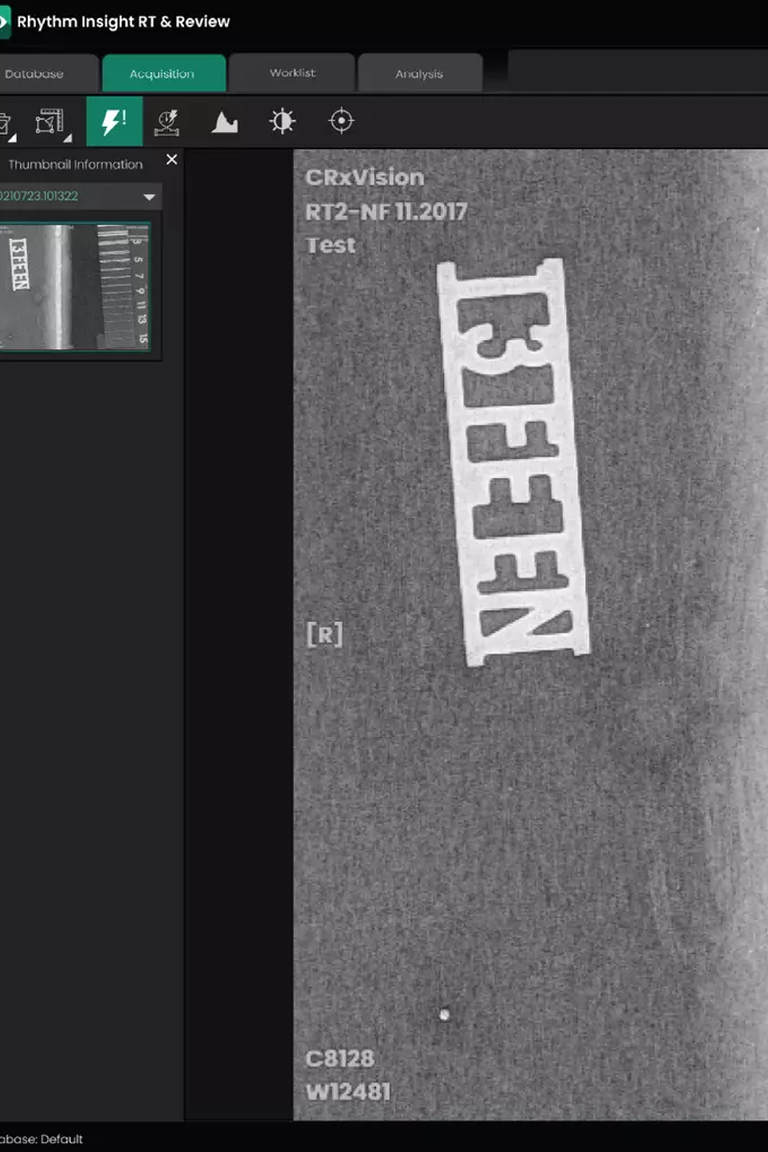

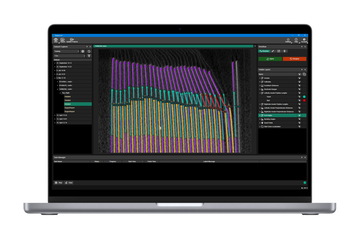

Connect data and people for smarter inspection results, faster with everything from radiographic testing, data analysis tools, to flexible data storage, to data management, real-time collaboration, and more.

Why use advanced NDT software tools

Reduce maintenance costs

Make data-driven decisions to reduce the cost of maintenance without impacting desired performance or risk.

Effectively manage risk

With a complete view of asset health and risk across your operations, you can prioritize activities that allow you to effectively manage risk.

Deliver predictable performance

Create a seamless connection between asset condition, strategy, defect elimination, and work execution to enable effective management of unplanned costs, mitigation of risk, and avoidance of catastrophic failure.

While 70% of organizations today have either implemented or are working on implementing a strategy for digital transformation, only about 16% have realized long-term performance improvements. Such organizations have the right intentions and understand the basic benefits of an asset performance management approach but results of a successful transformation are hindered by traditional silos of functions and data stores within their work processes.

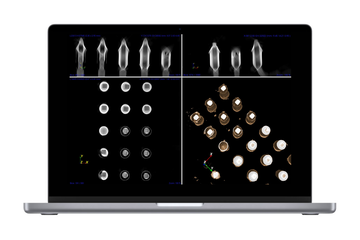

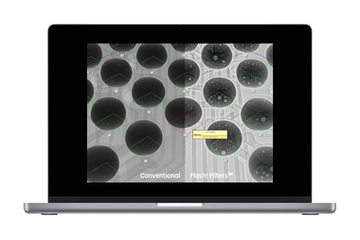

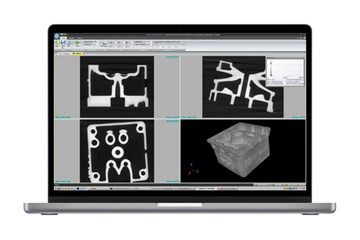

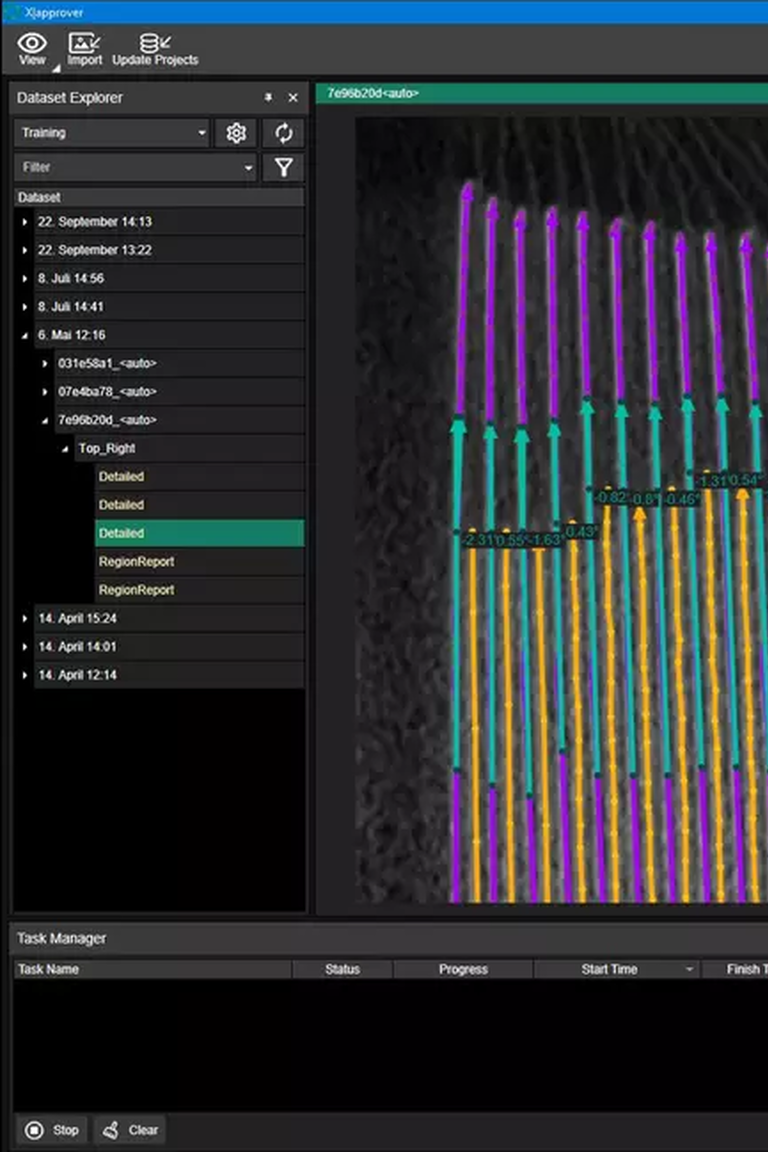

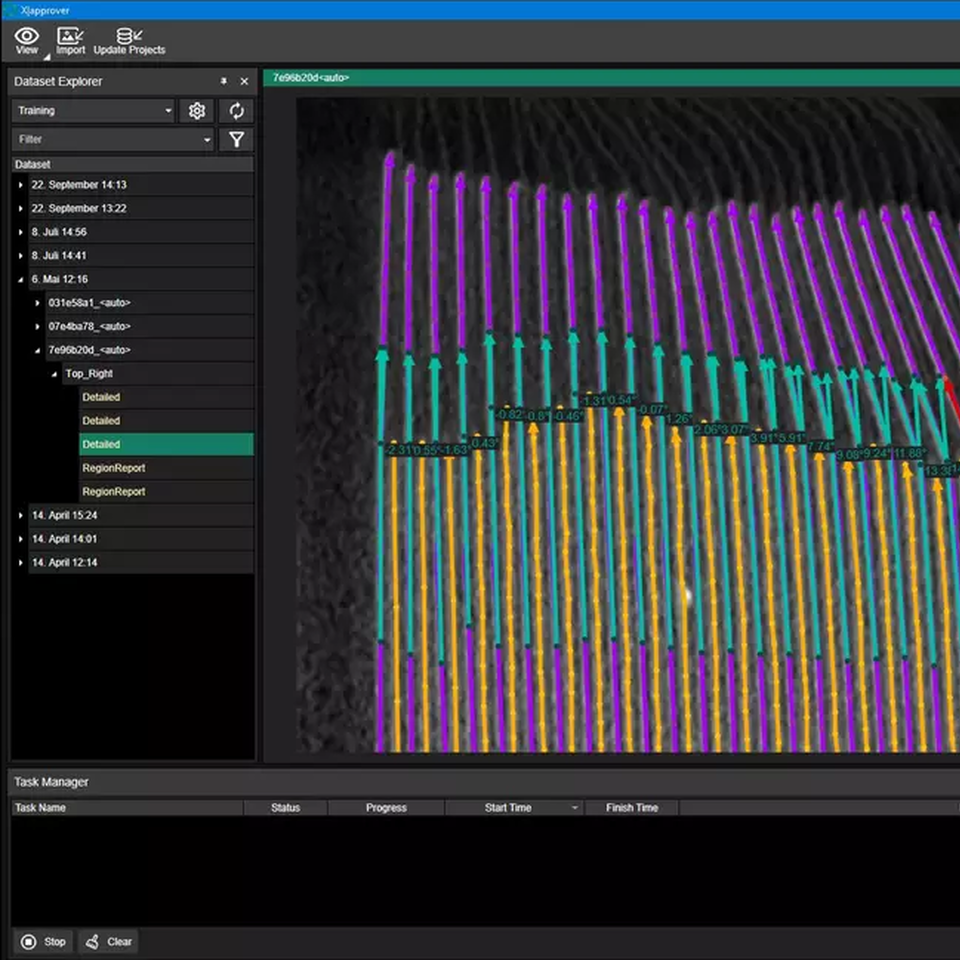

Software for automating your defect analysis workflow

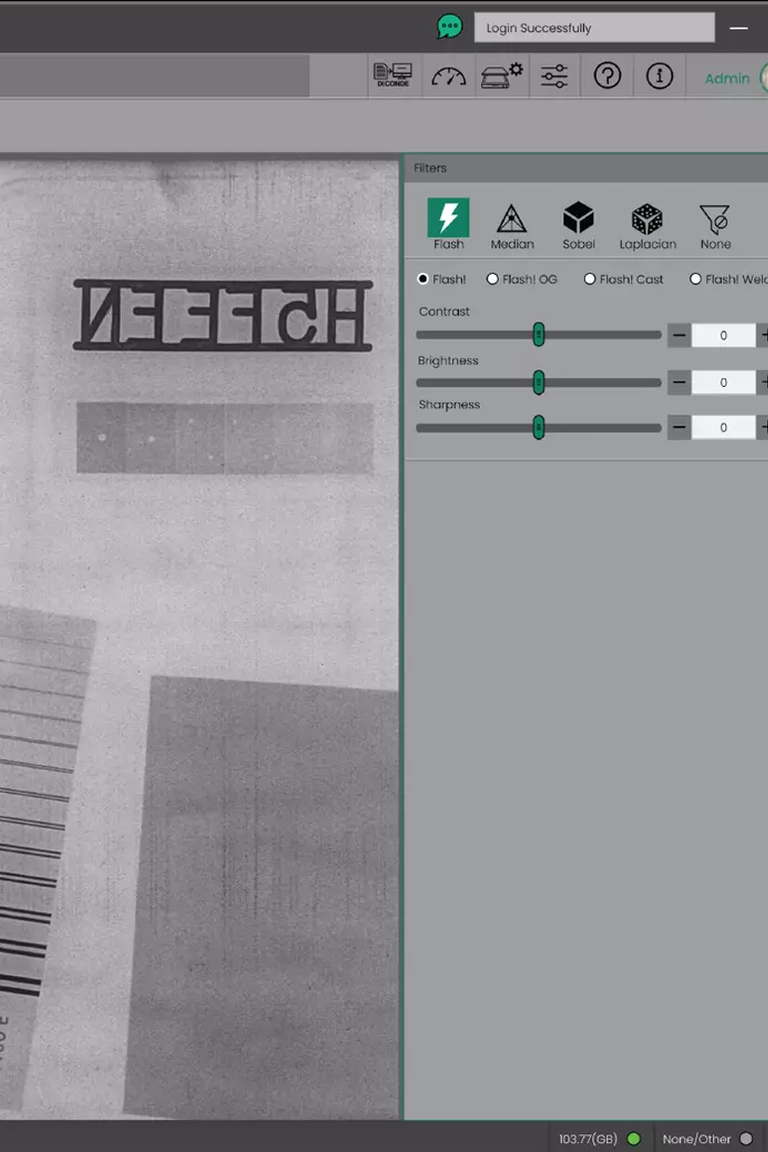

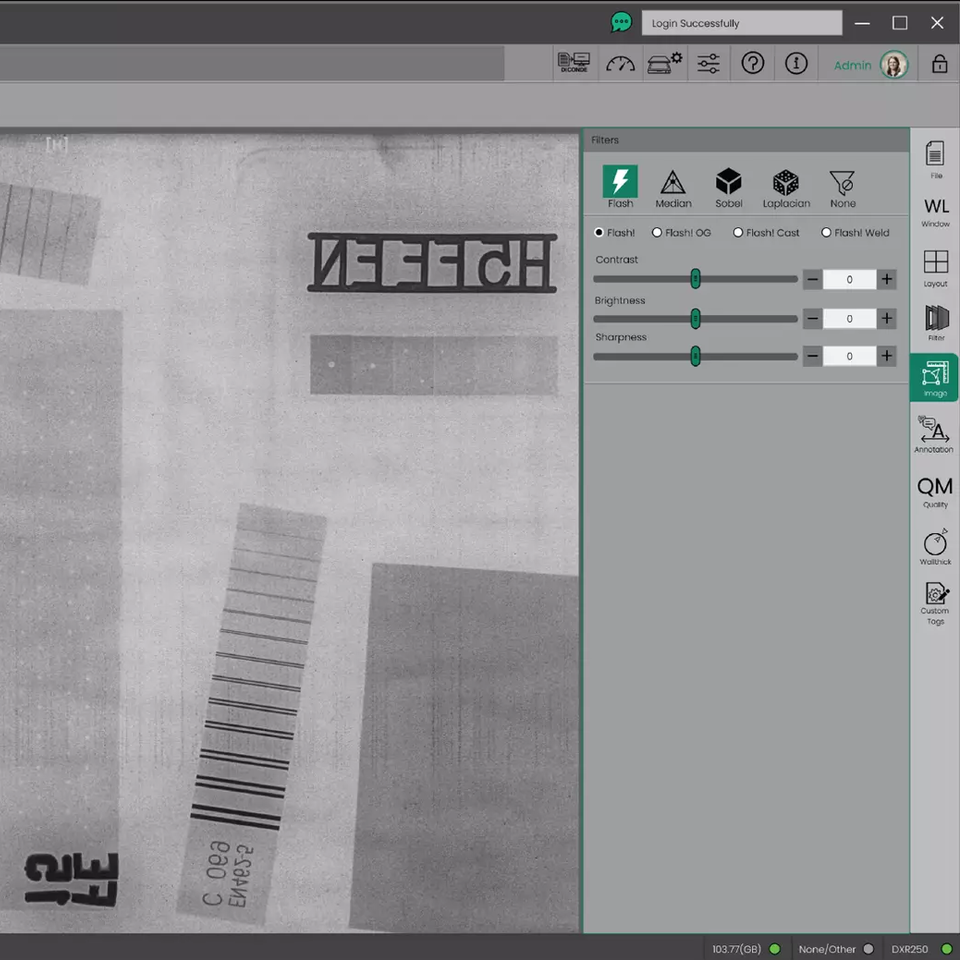

AI-based on-premises ADR software (Automated Defect Recognition) with specific teachable algorithms to evaluate the quality of components for a wide range of parts and leverage automated detection of microstructural defects from CT images