Overview

Overview

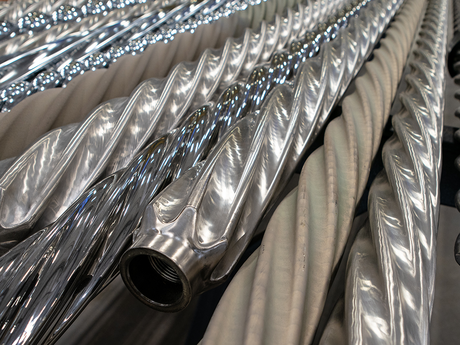

Navi-Drill™ Ultra™ Series motors from Baker Hughes have rugged, modular, and configurable power sections that deliver superior performance and high-quality holes. Motors stay in hole longer for one-run, casing-to-casing performance and durability to outlast the bit.

The internally designed power sections improve efficiency, increasing horsepower and torque at the bit. The drive train delivers higher torque to the bit in long drilling intervals and demanding conditions. Stronger connections and high-grade materials withstand dynamic applications, increasing reliability in straight and directional wells.

Navi-Drill Ultra HP and Ultra XL-HP motors use high-performance elastomers for additional power output without sacrificing steerability. The elastomers are designed for higher hardness and lower coefficient of thermal expansion to deliver 50% more torque and power downhole for difficult mud systems. Motors enhance this performance in harsh drilling environments further with high-endurance polycrystalline diamond compact (PDC) bits.

Customized for diverse applications

Flexible design options match the right bit and bottom hole assembly systems to predictably steer and position your well.

The recently launched Ultra Curve™ drilling motor provides the ability to drill high build curves while delivering precise directional drilling control to improve well productivity and efficiency while drilling shale wells. The motor features reduced bit-to-bend length and provides improved tool face control to complete the vertical, curve, and lateral sections in one run.

Our Ultra XL motors have the strongest power of the Ultra Series and deliver high torque at moderate rotational speed. They drill through hard rock formations using PDC bits, increasing rates of penetration (ROP) in straight-hole and tangent sections and building sections of extended-reach and horizontal wells.

Another new motor in the Ultra series is the Ultra XL45™ motor, which is designed to drill long, challenging, vertical sections with precise directional control. The motor’s high-torque capability minimizes stick/slip to boost performance and bit life, and with the longest power section in the industry, it provides unmatched power output and reduces drilling time.

Ultra HS and TS motors offer high-rotational speed at moderate torque. They drill hard, abrasive rock using high-performance, impregnated diamond bits. Shorter than turbines and less sensitive to pressure drops, they drill at higher ROP and accommodate higher flow rates. This improves hole cleaning and delivers more bit power in hard formations.

Low-speed motors use an extended stator profile, enabling higher flow rates, lower RPM, and higher torque. These motors deliver higher ROP for drilling hard rock with aggressive PDC bits. They’re ideal with compressible drilling fluids like air, aerated mud, foam, and mist.

Contact your local Baker Hughes representative today to find out how our motors can help you stay in hole longer.