Fiber optics solutions from Baker Hughes give you detailed, real-time data on the condition and performance of your downhole artificial lift tools—data you can use to make informed decisions to prolong run life, minimize interventions, and optimize production.

Gain detailed downhole insights in a single trip

Our SureVIEW™ Fiber Downhole Cable supports SureVIEW distributed sensing technologies, including distributed temperature sensing (DTS) and distributed acoustic sensing (DAS). Use these services to obtain detailed thermal and acoustic properties of the full wellbore to optimize your lift operations, stimulation jobs, and the long-term productivity of your well.

Our proven fiber optics technologies also support point measurement pressure/temperature gauges to monitor downhole pressure and temperature changes for ESP monitoring and sub-cool optimization. And strain sensing fiber optics systems give you insights into geophysical phenomena such as compaction and formation strains as well as an early warning of casing damage or buckling.

Ensure reliable operation in robust environments

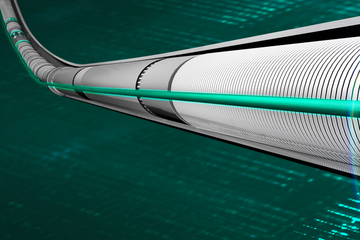

The SureVIEW downhole cable is encased in a 0.25-in. outer diameter (OD) metal armor containing a fiber-in-metal tube capable of housing up to 12 fibers. Deploy the optimal system in a variety of single-mode or multi-mode combinations, based on your application needs.

The metal armor is a corrosion resistant alloy (CRA) that protects the fibers from corrosive well conditions. And each fiber is designed for prolonged life in your most challenging downhole environments—ensuring seamless and reliable transmission of downhole data to the surface.

Contact us to find out how our fiber optics systems can help optimize your artificial lift operations for improved reservoir management.