Highlights

Highlights

Benefits

- Ensure faster run-in with slim-line design and solid construction that resists damage or premature setting

- Ensure packer remains properly set with two opposed sets of full-circle, full-strength slips

- Ensure a positive barrier to packing element extrusion with interlocking metal backup rings contacting casing

Applications

- Complex multi-string completions

- Permanent test packer applications

- Wireline-set packer applications

Overview

Overview

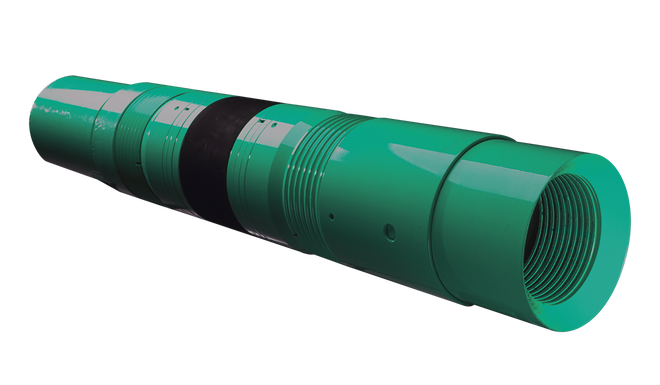

Get assured packer performance in a wide range of completions with the Wireline-set Signature™ series of packers from Baker Hughes.

- The Signature D™and Signature DB™ retainer production permanent packers are among the most widely used, most versatile, and highest-performing production packers available. The proven reliability of these packers also makes them ideal for your permanent test packer or bridge plug applications.

- The Signature DA™ retainer production packer has all the versatility and high-performance characteristics of the Signature D packer, but includes a larger sealing bore at its upper end. Use the DA packer in your complex multi-string completions or to maintain clearance through the packer during large tubing runs.

- The Signature F™ Series retainer production packer is the big-bore version of the D packer and features the largest bore through any drillable packer—ideal for running mill-out extensions or other components below your packer.

- The Signature FA™ retainer production packer is the big-bore version of the Signature DA packer. With an extended upper body that accommodates a larger upper sealbore, the FA packer provides a large inner diameter (ID) through the accessory and packer.

Optimize your completions with proven design advances

Wireline-set Signature series packers share common design benefits that deliver reliability, efficiency, and integrity to your completions operations.

- Signature Series packers’ slim-line design and solid construction save rig time, with up to 50% faster run-ins compared to conventional packers—without risk of impact damage or premature setting

- Each packer includes two opposed sets of full-circle, full-strength slips along with a smooth, continuous ID sealing bore—features which help ensure the packer will remain properly set

- Unique, interlocking, expandable metal backup rings contact the casing to create a positive barrier against packing element extrusion

- The packer’s packing element resists swab off, which further contributes to faster running times

- The packer’s body, slips, packing element, and other components are designed for ease of milling, thus shortening mill-out times and minimizing debris buildup in the well

Contact us to learn how the Wire-set Signature series packers can give you a reliable, permanent production packing solution for your wells.