Proven experience in CO2 handling

High compression of CO2 is critical for the transportation and eventual storage of CO2. Compressors need to be able to handle CO2 with materials that can withstand corrosive conditions.

We offer a variety of commercially ready solutions for high-pressure and corrosive conditions.

Ongoing innovation in composite pipe to transport CO2 safely

The technical demands posed by CO2 transport will require advancements in areas such as durable composite piping.

Our flexible products have a proven capability in CO2 rich environments, supported by our dedicated research program on the topic of stress corrosion cracking and permeation of CO2 into the pipe annulus.

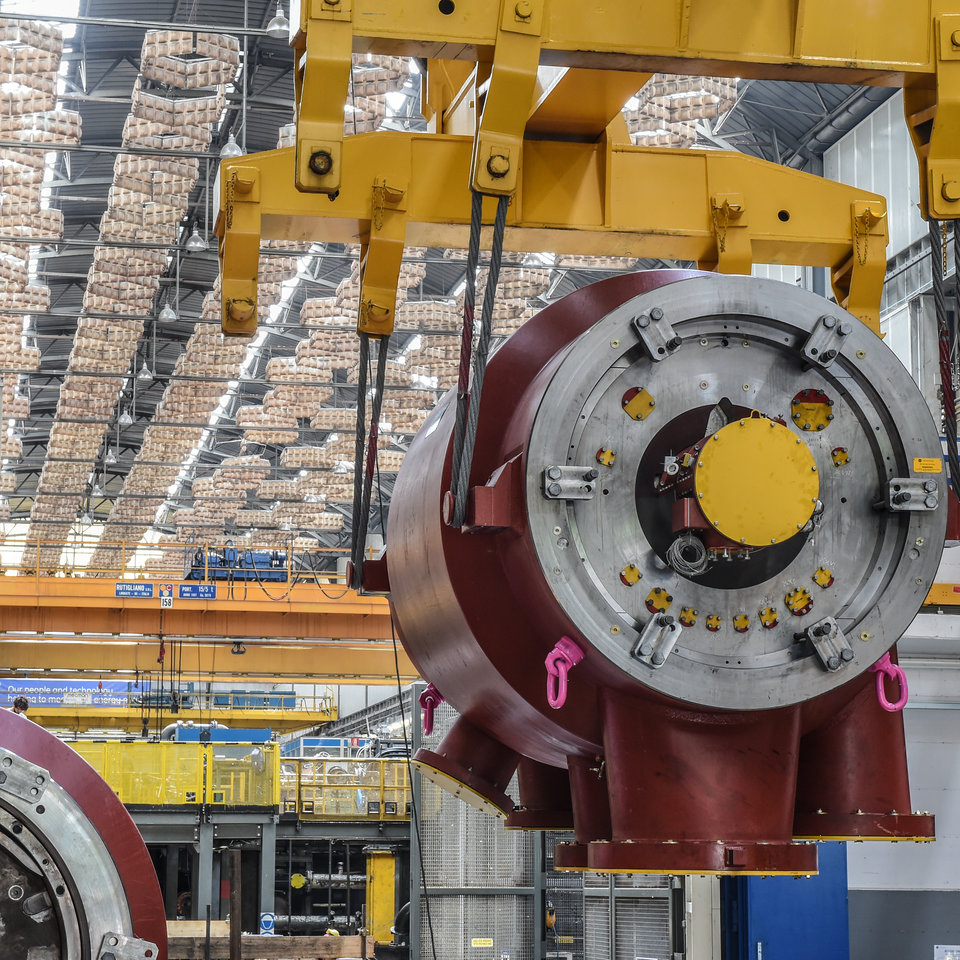

Leveraging 50 years of Baker Hughes experience in CO2 compression & transport

As we work to tackle the energy transition's toughest challenges, our portfolio of advanced compression technology is continuously evolving—ensuring we also meet the energy industry's most demanding requirements.

- CO2 compressors

- Solutions for high pressure applications

- Pumps, valves, and instrumentation

- Compressors control system

Start-up, routine inspection, shutdown, and venting of CO2 pipelines can differ considerably from natural gas pipelines. Baker Hughes offers a range of inspection and sensing technology to help protect our customers' ability to operate effectively.

- Nondestructive pipeline inspection

- Installed corrosion monitoring

- Flexible nonmetallic pipe

- Flow, gas, moisture, and pressure sensing

News and resources

While significant progress is being made, the industry needs to see a strong business case for CCUS. In addition to developing policies that promote investment in CCUS, DOE is investigating new ways to extract an economic benefit or additional value from capture CO2.