Overview

Challenges

- Deepwater well

- Pressure spikes

- Inclination build up from 48 to 88°

- HP/HT conditions

- Reactive shales and soft formations

Results

- Improved ROP 48%

- Increased flow rate 14%

- Maximized drilling efficiency

- Eliminated NPT and downhole losses

- Maintained adequate pressure and temperature controls

- Achieved total depth of 9,258 ft (2822 m)

An independent national oil company in Brazil required a synthetic drilling fluid for a challenging deepwater well. Located in the Atlanta field in the Santos basin, the well had a water depth of 5,088 ft (1551 m), a 143⁄4-in. (375 mm) section with a maximum anticipated density of 9.3 ppg, and inclination build up from 48 to 88°, landing at the top of the unconsolidated sand/sandstone reservoir. Constant rheology, lower viscosity, and fragile gel strength had to be maintained to promote effective hole cleaning and a successful casing run, while minimizing pressure impacts to protect the formation.

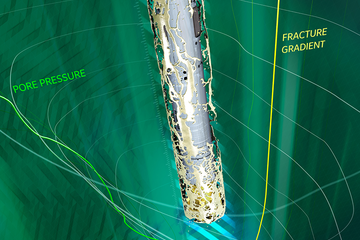

The fluid also needed to withstand high-pressure-high temperature (HP/HT) conditions, improve equivalent circulating density

(ECD), and manage pressure spikes compared to offset wells drilled with a paraffin-based conventional drilling fluid. The operational drilling window was narrow with pore pressure at approximately 8.8 ppg and formation integrity at 10.1 ppg. Reactive shales and soft formations were expected with risk of lost circulation. An accurate hydraulics analysis had to be performed to aid in eliminating downhole losses and nonproductive time (NPT).

Download the PDF to read the full case study.