Overview

Challenges

- Deviated borehole with complicated inclination

- Limited pumping capacity and drilling capability for large holes

- Formation of cuttings beds

Results

- Maximized flow rates

- Reduced pump pressures

- Achieved high tolerance to drill solids without major impacts on rheology

- Maintained low gravity solids at 11%

- Achieved drilling depth of 18,000 ft (5,486 m)

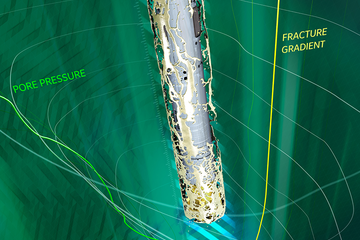

A development project in the Gulf of Mexico was restricted to a casing program which isolated trouble zones and mitigated any risks associated with a tight drilling window. Recent projects in the area had added additional sections to isolate lost circulation zones, and deployed a water-based mud system that would facilitate the treatment

of losses in the trouble zones.

The project was limited by the rig’s drilling capabilities for large-hole, deep-shelf wells. The 17 1⁄2-in. section had a maximum inclination of 65.96°, and the maximum pump rate of the rig was less than what was required to clean the hole. The inclination of the wellbore and the limited flow naturally promoted cuttings beds to form. The operator was seeking new technology that would allow for alternative wellbore geometries to expand their drilling capabilities.

Baker Hughes recommended the DELTA-TEQTM low-pressure-impact drilling fluid to reduce the equivalent circulating density (ECD) and allow a higher maximum flow rate while imparting minimal pressure on the formation. In addition, the fluid would provide better assistance with hole cleaning and suspension capacity required to clean a large deviated borehole at a 66° inclination.

Download the PDF to read the full case study.