Case study

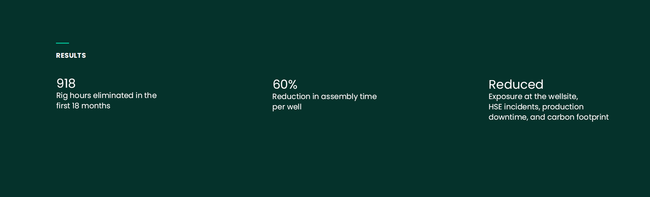

Pre-assembled ESP installation reduced assembly time by 60 percent in Argentinian field, saved 918 rig hours, $340K USD

Oct 08, 2024

Challenges

Solution

Two beams holding pre-assembled ESP unit at the wellsite.

Lifting a beam for an ESP install.