Highlights

Benefits

- Upgrade low-temperature waste and renewable heat for efficient process and district heating

- Electrifies heat supply to significantly reduce fuel consumption

- Powered by renewables, saves hundreds of thousands of tons of CO₂ each year

Features

- Efficient management of large volumes of low-grade waste heat

- Comprehensive solutions for decarbonizing process and district heating, displacing fossil fuels (Scope 1 emissions)

- Electrification technologies with competitive LCOH, providing steam up to 24 bar for manufacturing

Applications

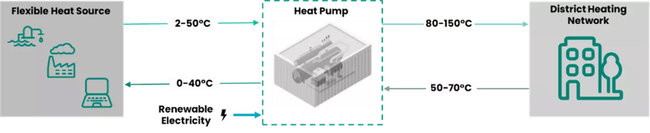

- District Heating: Hot water generation (80-120°C)

- Paper Industry: Steam generation (10-18 bar) for dryers

- Chemical-Refinery: Steam generation (6-24 bar) for reactors, distillation, CC regeneration

- Food & Beverage: Steam generation (8-18 bar) for evaporation, roasting, cooking, pasteurization, and distillation

- Alumina refinery: Steam generation (5-24 bar) for digestors

Overview

Industrial heat pumps offer a transformative solution for process heating and cooling, which currently accounts for 60% of global industrial energy consumption. At present, 70% of the energy required for temperatures between 100°C to 200°C is supplied by fossil fuels.

With the global energy grid’s renewable and nuclear share expected to increase from 35% in 2021 to 55% by 2030, the emission factor for electricity is set to decrease by 40%. This shift highlights the importance of heat electrification in the decarbonization process.

By integrating industrial heat pumps, industries can reduce their reliance on fossil fuels, enhance energy efficiency, and align with broader sustainability and emission reduction goals.

Process Heating: Advanced Electrification for Diverse Industries

Our Industrial Heat Pumps and Mechanical Vapor Recompression technologies offer advanced solutions for steam generation across various sectors, including Pulp & Paper, Chemical Refinery, Food & Beverage, Mining, and Metals. These systems provide high individual capacities ranging from 5 to 50 MW and can produce steam at pressures of 12 to 24 bar and temperatures up to 280°C.

Key features include:

- Efficient steam generation: Capable of generating steam at high pressures and temperatures, tailored to specific industry needs.

- Valorization of low-temperature waste heat: Utilizes industrial water and low-pressure steam at 30 to 160°C to enhance overall efficiency.

- Environmentally friendly working fluids: Employs hydrocarbon (HC) fluids, contributing to a reduced environmental impact.

- High efficiency: Achieves a coefficient of performance (COP) of over 55-65% of Carnot entitlement.

- Compact footprint: Designed with a space-efficient footprint of 5-40 m2 per MW.

District Heating: Efficient Electrification for Municipalities

Our Industrial Heat Pumps provide advanced solutions for centralized space and district heating, designed specifically for municipal applications. These systems offer high individual capacities ranging from 10 to 50 MWth and deliver hot water at temperatures between 80°C and 120°C.

Key features include:

- High delivery temperature: Efficiently produces hot water within the 80-120°C range, meeting diverse heating needs.

- Flexible heat sources: Capable of utilizing various heat sources such as sea water, sewage wastewater, data centers, and cooling systems operating at 2-50°C.

- Environmentally friendly working fluids: Uses natural refrigerants with zero ODP and negligible GWP.

- High efficiency: Achieves a coefficient of performance (COP) of over 60-65% of Carnot entitlement.

- Compact footprint: Features a space-efficient design with a footprint of 15-30 m2 per MW.