Composite materials for pipelines can support the transport of new fuels and help increase efficiency— meet the team working on making it real.

Wa’el Tashkandi is the CEO of Novel Non-Metallic Solutions, leading the establishment of this 50/50 joint venture between Baker Hughes and Saudi Aramco. Wa’el has a vast experience across the oil and gas services and manufacturing sectors. Here he discusses the new non-metallic solutions partnership, the team’s current projects and why he’s excited about the inauguration later this year and the future for Novel.

I am the CEO of Novel Non-Metallic Solutions. We are a non-metallic growth platform based at the world-class King Salman Energy Park (SPARK) in Saudi Arabia. A kind of energy technology ‘start up’ if you like.

This joint venture, which we announced in 2020, is a multi-sectorial non-metallic investment designed to innovate, develop and manufacture composite materials for both oil and gas as well as non-oil and gas applications. Paving the way for the future of our industry, as I see it.

It is a true partnership between two global market leaders as it combines the technical expertise of the world’s largest oil producer Saudi Aramco together with the leading-edge manufacturing technologies developed by Baker Hughes for the enhancement of non-metallic composite products. Our team is simultaneously executing projects with multi-sectoral applications and actively seeking viable capital investment opportunities to advance the energy transition.

It’s really exciting and happening at a critical time for our country and the world. Our JV partners are committed to supporting Saudi Vision 2030 and IKTVA’s targets and the renaissance of demand for petroleum as a raw material, to produce high value non-metallic products.

The focus on non-metallic materials for us as industry experts is intended to add to the efficiency and reliability of operational assets for our customers by reducing the effects of corrosion. This is key to preventing failures and reducing downtime. It’s both about cost and risk management.

This JV aligns with Aramco’s strategy to seek new opportunities in oil-based products, which not only offer performance benefits but also aim to reduce carbon emissions. Baker Hughes continues to strategically invest for growth in non-metallic materials, helping customers lead in the energy transition, and help address the corrosion and cost of ownership challenges with conventional steel pipe for the energy, oil and gas and industrial sectors. The combination of these partners brings the applications and deployment knowledge from Aramco’s side with the technical know-how in manufacturing from Baker Hughes.

Domestically, Novel will expand the commercial ecosystem and promote local investment, which is very important to our people. The new facility will not only create jobs; it will also help foster growth of an emerging and innovative sector in alignment with the Kingdom’s Vision 2030.

In more practical terms, we are establishing an agile research and development center of excellence focused on non-metallic technology. Our team is already building local expertise and technological capability to produce sustainable, non-metallic composite solutions of the highest-possible quality for a wide range of industries across the Middle East and North Africa region.

But it’s not just about two large partners: in this ecosystem, we want to be an enabler of locally based SMEs. With leading edge R&D, we can drive and enable a global and regional need for transformation of the energy sector by reducing its carbon footprint, maintenance costs and risk altogether. We are all part of the solution.

Non-metallic products are reshaping the industries and products we all depend on, it’s as simple as that. Because they are more reliable, cost effective and offer sustainability benefits.

Our JV partners also share similar values. We are adopting HSE techniques which focus on the employee’s positive response to manage and effectively control any potentially hazardous health and safety environment. I personally make sure every employee is empowered to facilitate and promote a proactive learning environment within the workplace, where everybody in the organization is committed to our renowned health and safety culture. I am passionate about promoting such a caring and preventative culture, where no one gets hurt.

Right now, we are focusing on non-metallic pipe applications, onshore. Our in-house engineering and field-service teams currently provide engineering support and recommendations to operators’ design teams and field crews. This typically includes line modelling, flow assurance and pressure-curve analysis to ensure proper sizing, application and installation. Our modelling process presents various options and can help operators decide which option to choose to best fit project requirements. It’s pretty smart.

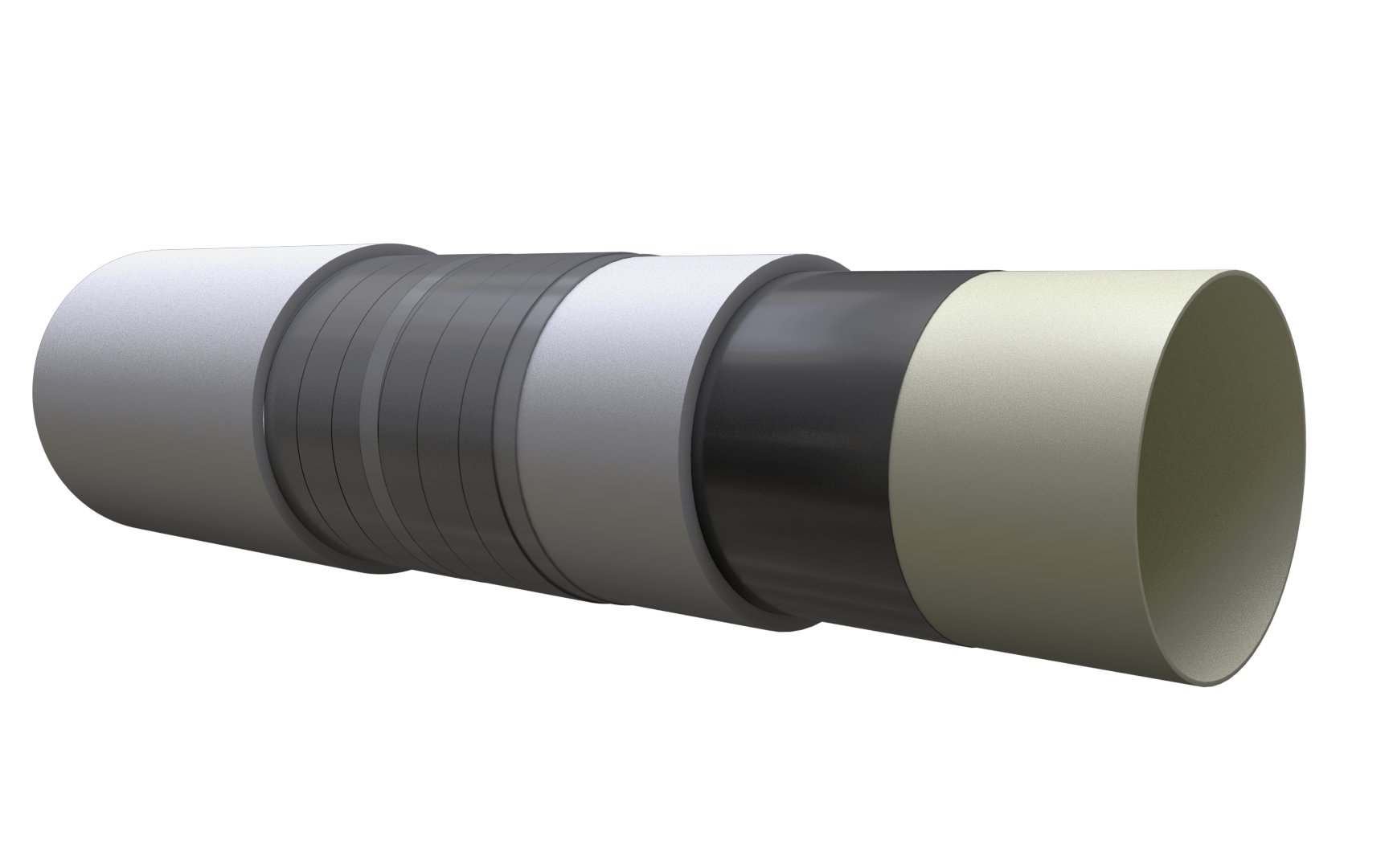

Ultimately the JV really aims to promote the use of reinforced thermoplastic (RTP) pipes which consume less energy to produce and are less carbon intensive compared to conventional steel pipes. This is so important on our path to net-zero.

Our pipe products right now go up to 8’’ in diameter, with applications up to 2250 psi of fluid pressure, and 180 degrees Fahrenheit of operating temperature. Whether we are installing a new line or rehabilitating an old one for our customers, three main technologies support different applications:

- For example, I would recommend the nylon-lined pipe for high pressures and temperatures, permeation and paraffin build-up,

- on the other hand, the polyphenylene sulfide (PPS)-lined pipe is suitable for extremely corrosive environments with high H2S, CO2 or bacteria.

- Finally, the high-density polyethylene (HDPE)-lined is designed for transport or disposal of fresh or produced water.

A pipe for every job if you like.

During installation, our experienced field-service technicians ensure projects run smoothly, either through executing the job, supervising the crew or even training contractors. They are used to accommodating multiple methods for deployment depending on the unique needs of each project.

To meet growing demand, we’ve been busy setting up service capabilities to cut and deliver pipes to length. Exact length required for specific projects are manufactured to order, to maximize flexibility in design. This is one way to incorporate cost savings too. Pipe lengths are delivered on reels to field locations directly from the manufacturing facility. In addition to this logistical support, the Novel teams work onsite to assist in staging the installation equipment and unspooling the pipe from the reels, managing connections and training customer staff.

Before commissioning, setting up and performing a hydrostatic test correctly is crucial to properly deploying the non-metallic spool-able pipelines. Once again, our teams are working with operators’ teams to make this happen as smoothly as possible.

Our team is working on a few non-metallic projects to tackle customer pain points and lower total cost of ownership. An example is by using current offerings of reinforced thermoplastic pipes (RTP) as velocity strings in oil wells to enable stable production in declining reservoir pressures. That would revive wells and delay the need for artificial lift that require additional power and CAPEX, especially in remote sites.

If you compare these RTP velocity strings to metal alternatives, you bring the value of rig-less deployment through coiled tubing units, without the need for a workover rig or allowing drilling rigs to drill more wells per year. In addition, the smooth non-metallic materials in these RTP strings allow higher flow rates for the same diameter and ensure a long lifetime without corrosion or scaling issues.

Such a multidisciplinary project is directed by the team collaborating with experts from different backgrounds from pipe manufacturing to downhole deployment and operation.

So, we are have two main workstreams delivering our our Research and Development strategy.

Workstream 1, which starts once we are operational later this year, focuses on RTP flowlines. In this instance, we will leverage Baker Hughes’ existing flexible pipe solutions both designed for onshore and offshore applications.

In Workstream 2, we will concentrate on downhole production tubing technology. The team will focus on downhole tubular development and qualification due to the great market potential driven by the need to eliminate downhole corrosion issues.

Novel’s shareholders have allocated 10% of their equity to develop downhole tubulars solutions that are challenging the status quo in terms of their temperature and pressure ranges. After a detailed comparison between different market offerings, we identified a market gap that Novel is working to cover by producing downhole solutions that can withstand high ranges of temperature and pressure. Novel is not only focusing on developing the “pipe” solutions itself, but we are addressing the downhole system and infrastructure challenges related to utilization of non-metallic components in drilling, completion, logging, intervention, and production conditions.

In parallel to the two workstreams we are exploring adjacent markets. For example, one application could be for hydrogen pressure vessels for fuel cell vehicles. This is an area where we are paying special attention, monitoring current market trends and energy transition strategies from both Baker Hughes and Saudi Aramco.

For sure, we have designed an R&D Program which will expand into other products and applications beyond oil and gas and offering innovative solutions aimed at packaging, renewables, automotive and even the building/construction industry in the not-so distant future. This is indeed very exciting.

Today as you may know, non-metallic applications are already being deployed in these industries, with products including flowlines, downhole production tubing, vessels, pumps, and cooling towers, all of which are manufactured from non-metallic materials such as plastic, carbon fiber and glass fiber.

We are looking at leveraging this expertise and technology transfer. For example, composite pipes provide advantages compared to steel pipes in many applications in the mining industry including brine lines, slurry lines, dewatering lines, well wells, hydrometallurgy, compressed air lines and underground service lines. They offer higher resistance to abrasion, erosion and harsh chemicals, while providing high pressure capability and protection against expansion. In addition, pipe spool-ability allows installation over difficult terrains in remote and populated areas. Such benefits can help mining companies to achieve cost savings and realize better equipment lifespan.

For me, what’s exciting is that there is so much going on in this space. I am inspired by the energy and collaboration at work to make these new technologies a reality, from innovation to incubation through to commercialization.

As an example, Saudi Aramco recently opened the Non-metallic Innovation Center in the United Kingdom in collaboration with the UK-based Welding Institute and the National Structural Integrity Research Centre to conduct research and development of non-metallic technologies. The center collaborates with leading academic institutions and manufacturers to develop, test, and market new products. This is truly what embodies this industry: people who want to find the solution and work together to make it happen. We are ready!

Energy Forward Stories

Sign up to stay up to date on the latest innovations and people shaping the future of our industry.