Overview

Achieve continuous downhole pressure and temperature information in high-temperature environments and thermal stimulation, steam injection operations up to 260°C

Traditional 150°C to 175°C (302°F to 347°F)-rated electronic gauge technology has been shown to operate up to 265°C (509°F), but with very low life expectancy. Zenith™ HT (high-temperature) gauges enable dependable downhole surveillance despite today’s challenging production environments, paramount in ensuring continued delivery of well data essential for efficient production.

Accurate pressure data are important in understanding reservoir and well performance. In harsh, high-temperature operating environments, knowledge of downhole conditions is especially critical to stay ahead of potential issues and to ensure enhanced performance and well productivity.

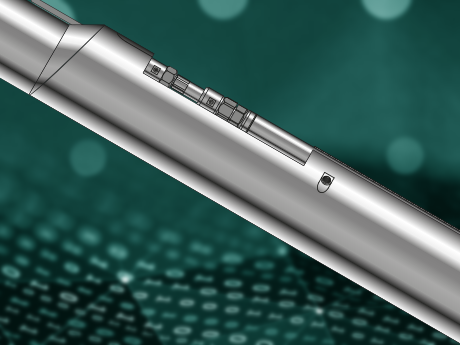

Zenith HT gauges are developed from robust technology that performs in these high-temperature environments, unlocking optimized production and reservoir drainage. HT gauges are available in 225°C (437°F) and 260°C (500°F) temperature-rated options for electrical submersible pumping (ESP) and non-ESP applications. These high-pressure, high-temperature gauges extend current sensor and cable limitations with rugged designs, allowing for reliable monitoring of hot reservoirs or excessive temperatures generated by pump systems, thermal stimulation, or steam injection operations such as steam flood and steam-assisted gravity drainage (SAGD) wells.

Knowledge gained from real-time, direct measurements enables operators to reach optimum output and maximize performance while ensuring the artificial lift system is protected. With field-proven survivability, a heritage of reliability and engineering excellence, as well as compatibility with all ESP and artificial lift manufacturers’ equipment, Zenith HT high-temperature gauges provide a proven and dependable solution.

Contact your local Baker Hughes representative for more information.