Overview

Liner hanger/packer systems from Baker Hughes provide specialized, premium features that let you lower liner deployment costs and maximize the benefit of reducing casing diameters in your wellbore.

Whether you want to deploy heavy, big-bore liners instead of long strings or design a well plan with low annular clearance, our exceptional liner hanger/packer systems deliver significant cost and time reductions.

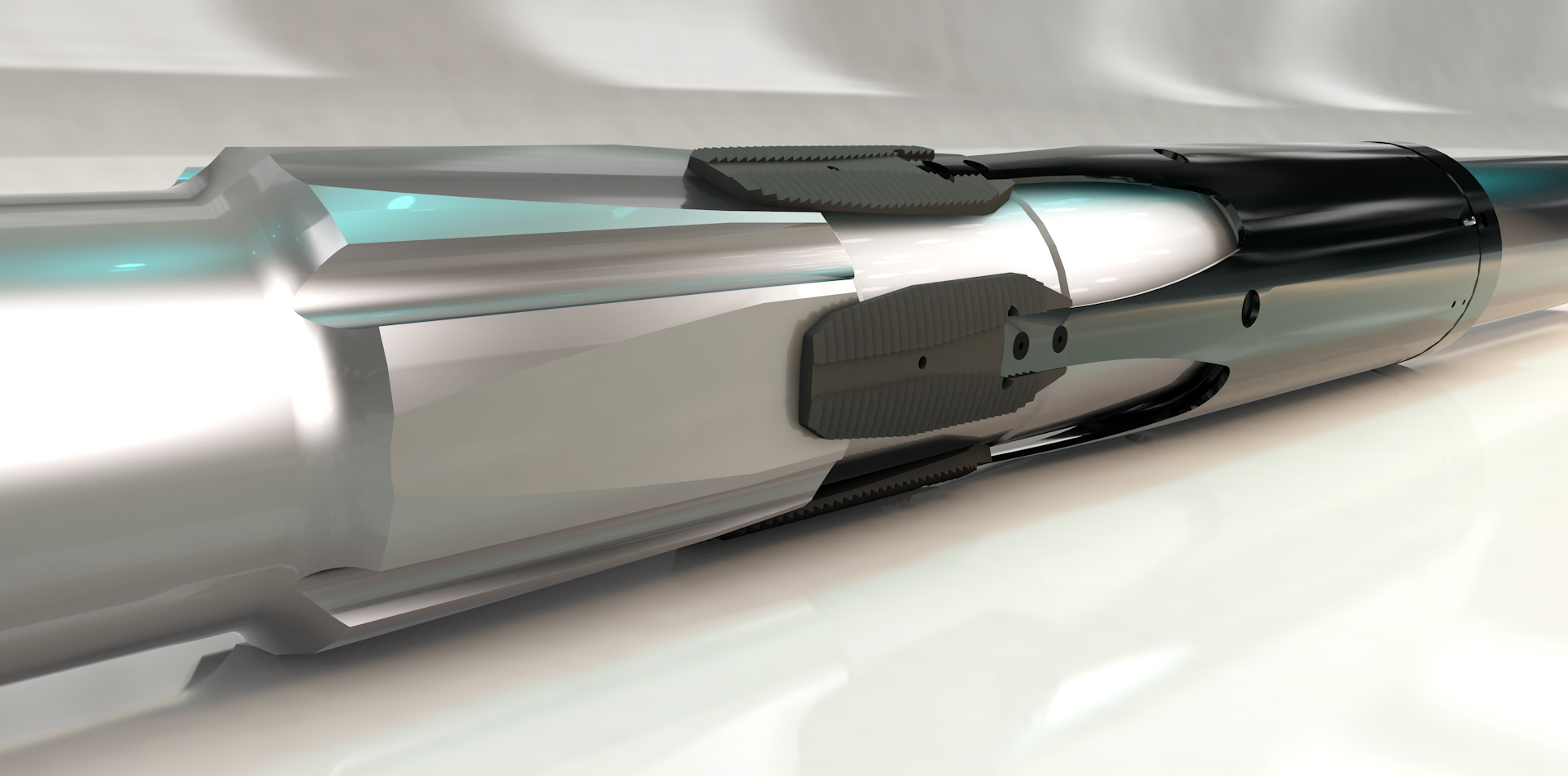

The INLine™ liner hanger/packer systems specifically addresses the challenges of installing tight-clearance liners. The INLine system achieves exceptional performance by combining several leading-edge technologies into a single tool—including the innovative, hydraulically actuated liner hanger with FLEX-LOCK™ style slips and a compression-set liner top packer that utilizes ZX™ technology.

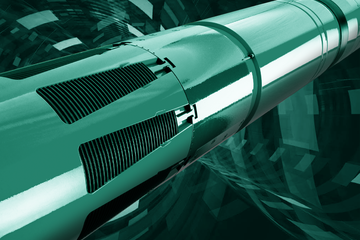

The Z-Flex™ liner hanger/packer is ideal for large-size liner jobs that demand premium ratings and performance. The Z-Flex’s high hanging capacity allows for long, big-bore liners to be deployed—reducing weight on the wellhead and reducing the amount of big-bore casing that you need to buy. And compared to cementing a long string to surface, the Z-Flex’s V0-tested liner top seal provides an additional barrier for improved safety.

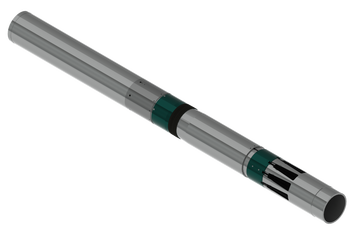

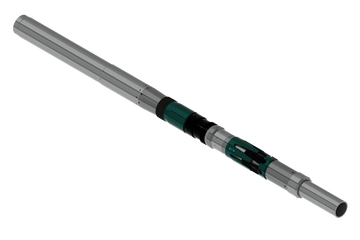

The UniFlex™ Pro system is the industry’s first hanger system built on a single body—without any internal connections—and is qualified to the V0 qualification for packers and bridge plugs. All moving components are rotationally locked to the body, preventing damage to the seals and extensions from backing off when the liner is rotated down to the bottom of the well.

The BAKERLINE™ hanger/packer system delivers an economical hanger solution for your medium-to-long liner lengths and high-angle wells. Built on decades of run history and field expertise, the BAKERLINE system withstands harsh downhole conditions and is API 11D V3-qualified to 10,000 psi (689.5 bar) and temperatures ranging from 82-300°F (27.8-148.9°C).