Highlights

Highlights

Benefits

- Ensure high circulation rates and debris removal without packing off

- Get uniform contact with casing as slips are tied to a common activator ring

- Ensure reduced pressure drop and minimal tool length when working through dog legs

Applications

- Formations that require aggressive reaming to get the liner to depth

- Difficult formations with dog legs

Overview

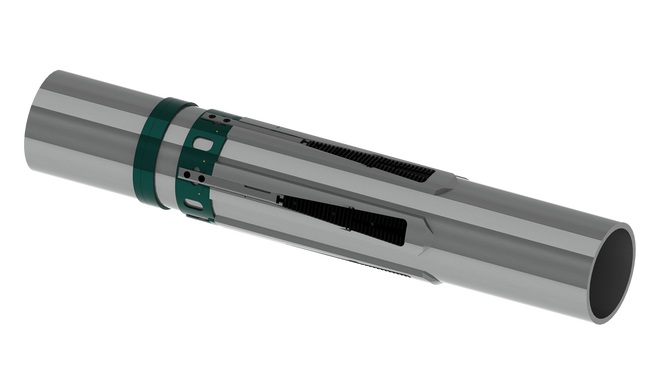

Ensure your liner gets to depth through rough formations with the SDD™ hydraulic-set liner hanger from Baker Hughes. With its rugged, solid-body design, the SDD liner hanger can withstand aggressive rotation for many hours as the liner is worked to depth, ensuring reliability when difficult formations are encountered.

Get assured liner running to depth

The solid hanger body is machined from one piece to deliver durability, complete protection for the slips, and to provide a large fluid bypass area for unimpeded circulation of cuttings and debris. The aggressive cutting shape of the skids helps break up cuttings while the liner is being worked down, and carbide buttons reduce outside diameter (OD) wear.

The SDD comes standard with heavy-duty slips to provide high load capacities. The hanger slips are actuated by discrete pistons, rather than by a hydraulic cylinder, which improves burst and collapse ratings over conventional hydraulic-set hangers. Pressure acting on the setting pistons generates the force to stroke the activator ring. As a result, fluid channels can be milled as deep as the OD of the liner between the slip cavities. And because there is no hydraulic chamber, burst and collapse ratings are typically equal to mechanical-set hangers.

With its compact design, the SDD liner hanger reduces the pressure drop and helps assure ease of movement when working through dog legs.

Contact us to learn how the SDD liner hanger can optimize liner running in your challenging formations.