Overview

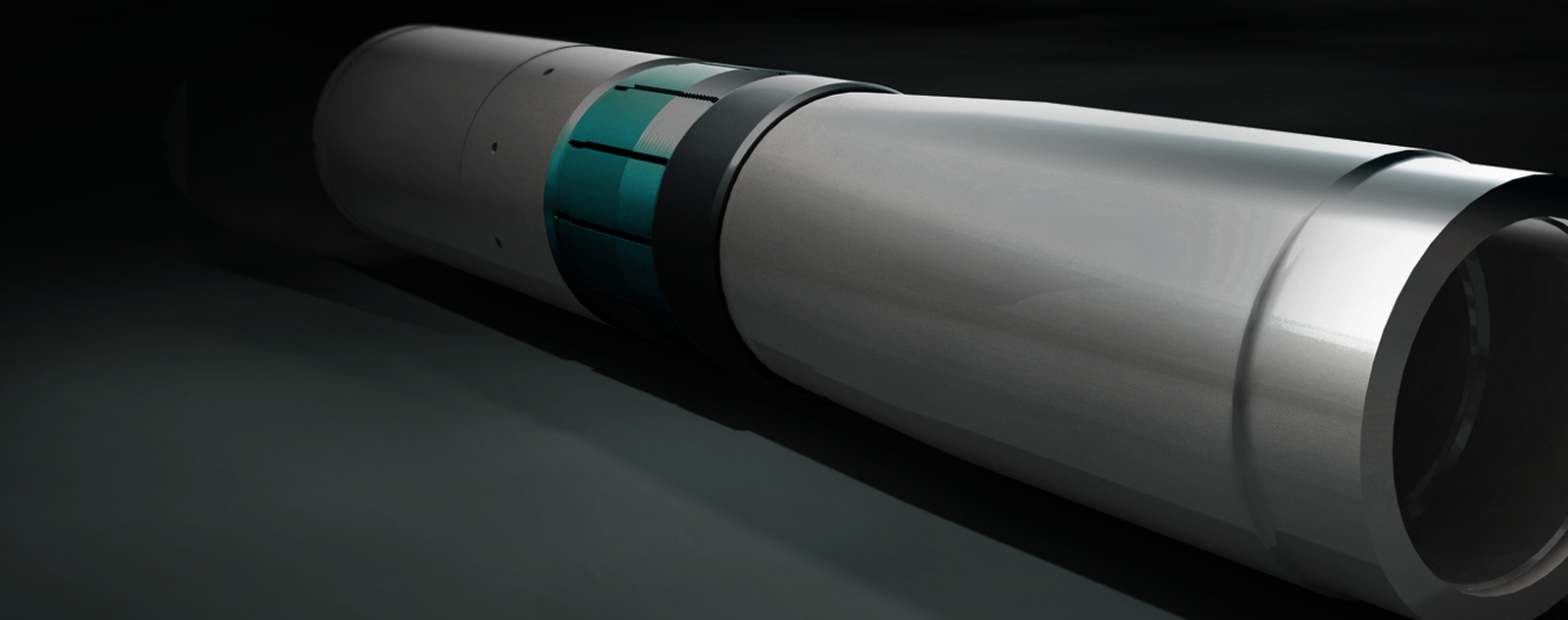

Liner top packers from Baker Hughes give you an effective annular seal between the top of the liner hanger and the casing—preventing formation breakdown, loss of cement slurry, and gas migration above the liner top during cement curing.

Our liner top packers feature multiple options for setting, including mechanical, hydraulic, and compression sets. They can be deployed in moderate environments of 10,000 psi (689 bar) and up to 300°F (149°C) to extreme high-pressure/high-temperature (HP/HT) and high-pressure/low-temperature (HP/LT) conditions requiring a pressure rating up to 15,000 psi (1,034 bar) and 450°F (232°C).

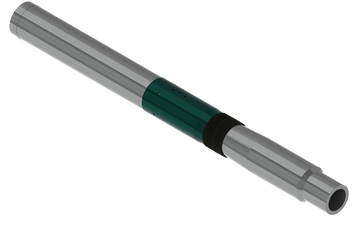

The Hyflo™ III liner top packer gives you a reliable seal in your low-to-moderate duty applications. With its one-piece seal element with bonded metal backups, the Hyflo III assures you a reliable seal while preventing extrusion and swab-off.

The ZXHD™ liner top packer with holddowns combines the proven V0-rated sealing capabilities of the ZXP liner top packer with a streamlined design with fewer moving components for improved reliability. It is designed to withstand the most extreme wellbore conditions, with rotationally locked extensions, bidirectional slips, and integrated holddown capabilities.

The ZXP™ liner top packer delivers a robust, long-lasting annular seal with reliable V0-rated sealing capabilities. And with hold down slips as part of its design, the ZXP prevents upward movement of the liner.

The ZXPN™ liner top packer gives you assured wellbore protection in your high load capacity and low equivalent circulating density applications. The ZXP N packer also incorporates a hydrogen nitrile (HNBR) elastomer-molded seal element that provides a high pressure rating (10,000 psi) and moderate temperatures (300°F maximum).

The ZXtreme™ HP/HT liner top packer is a next-generation technology that can withstand extreme HP/HT and HP/LT conditions to 15,000 psi (1,034 bar) at 100 to 450°F (38 to 232°C) in deep, hostile environments. Incorporating FLEX-LOCK™ slips for superior holddown capabilities, the packer is rotationally locked to prevent component back-offs when liner is rotated to setting depth, and is tested beyond API1 11D1 V0 to accommodate high- and low-setting temperatures.

Contact us today to find the optimal liner top packer solution for your completion.