Highlights

Highlights

Benefits

- Reduce well completion times and expenses due to fluid losses

- Minimize formation damage and the need for expensive acid treatments

- Keep work string in the well from perforating to packing for greater safety and control

Features

- Cased hole perforating

- Cased hole frac packing

- Time-sensitive fac-pack wells

Overview

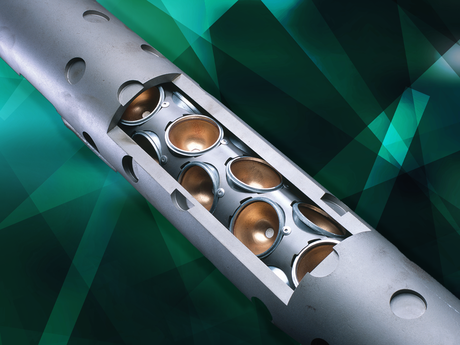

Ensure effective perforating and sand control with the Baker Hughes PERF-FRAQ™ perforating and frac-packing system. Combining the latest tubing conveyed perforating (TCP) gun system and frac-packing systems, the PERF-FRAQ system gives you a time-saving, cost-effective solution to perforate and frac pack your sandface completions in a single trip downhole.

Optimize completions with a full suite of tools

The PERF-FRAQ system includes the full range of components required for safe, assured perforating and frac packing.

- A hydraulic bottom gun anchor (HBGA) allows the TCP guns and firing heads to drop into the well sump immediately after gun detonation. This saves considerable time that otherwise would be required to pull guns out of the hole before running in with frac packing equipment. It also reduces the logistical concerns associated with pulling out of hole with guns and running in with the frac-pack assembly.

- The extensively tested, resettable RS-DG™ packer functions as both the perforating and sump packer. Because it needs only pick-up and set-down weight to be released or set, the RS-DG packer eliminates the undesirable task of rotating long assemblies of pipe and tools.

- The ball-on-seat spear (BOSS™) tool allows for easy and unlimited disengagement from the TCP assembly and re-engagement of the frac-pack assembly into the TCP assembly. This disengagement allows the frac-pack assembly to be moved to a safe distance uphole to avoid detonation shock damage.

- The PulsFrac™ wellbore dynamic-event modeling software precisely calculates a safe distance from the guns as required by the frac-pack tools. This software, a leading wellbore dynamic-event modeling for the energy industry, is based on nearly 20 years of actual data verification. It is also based on energy release equations for the source and solid rock mechanics equations for fracture initiation and propagation that enable the software’s precise calculations.

The PERF-FRAQ system also uses CK FRAQ™ frac-packing tools, TCP guns, and hydraulic firing heads. The HP-2 setting tool, which is used to set the SC-2 packer for frac-packing applications, is insensitive to pressure surges of up to 3,600 psi (248 bar). As a result, it eliminates the danger of presetting the packer during gun detonation.

Install the PERF-FRAQ system in one of two ways:

- Run the entire system on pipe, perforate, and frac pack—all in one trip. Select this method when time is a major factor and the weight of the TCP gun stack and HBGA exceeds the weight limitations of an electric wireline.

- Run the HBGA and TCP assembly on electric wireline, followed by running the CK FRAQ assembly on pipe, perforating, and frac packing. This method is particularly useful when the weight of the TCP stack and HGBA does not exceed the weight limitations of the electric wireline.

Contact us today to learn more about how the PERF-FRAQ system can seamlessly perform a perforating and frac-pack sandface completion in one trip.