To assure produced fluid flow and protect your production infrastructure from plugging and corrosion, you need reliable injection systems for your production chemical treatments. Chemical injection systems from Baker Hughes help enhance the efficiency of your production equipment and lines, both downhole and at surface.

Reliable injection suited to your system

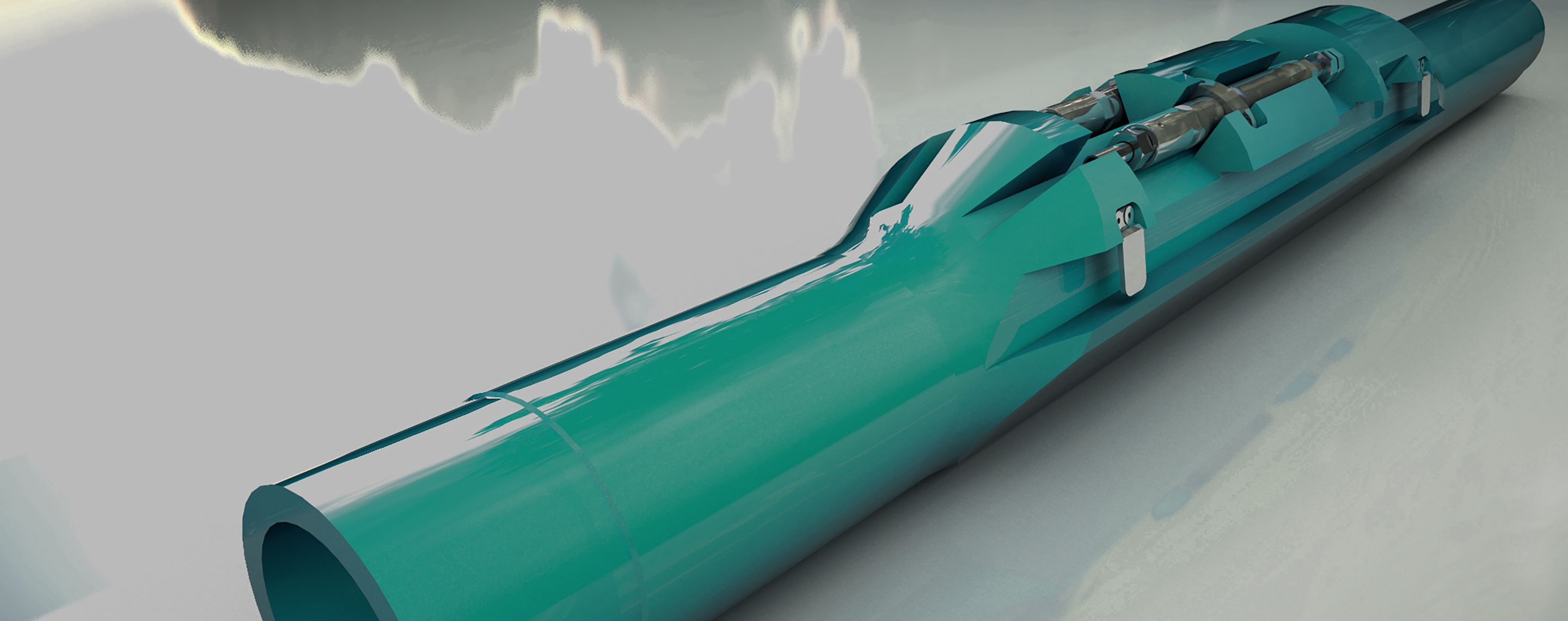

Systems like the Baker Hughes SureTREAT™ chemical injection system ensure that each treatment chemistry is reliably delivered at the right dosage and injection rate into your production system. Work with our application experts to develop the optimal injection system for your specific treatment challenge.

Choose from our wide array of check valves, control line connectors, and multi-slotted mandrels to design an injection system that won’t leak, plug, or degrade over time. Each chemical injection system is designed in accordance with your specifications and compliant with all local rules and legislation.

Your entire production system benefits in several key ways from the precise chemical placement that our chemical injection systems deliver.

- Inhibit harmful deposition. Inject inhibitors designed to mitigate against agglomeration, precipitation, and buildup of asphaltenes, waxes, and scale in your downhole tubulars and surface processing system

- Keep corrosion at bay. Inject corrosion inhibitors to prevent deterioration of equipment due to wall loss and increased solids in your produced water

- Keep your system flowing. Inject chemicals designed to maintain the flow capacity of flowlines and avoid production rate declines due to pressure drops or blocked downhole systems

- Boost production capacity at less risk and cost. Inject our array of treatment chemistries to improve your production rates and processing equipment performance while reducing the risk of downtime for costly acid or chemical cleanouts

Let’s work together to determine the most efficient chemical injection system for your specific treatment needs.