Highlights

Highlights

Benefits

- Tungsten carbide hardfacing for an active cutting structure for reaming and backreaming

- Steel alloy construction increases ROP and maximizes durability

- Patented concave profile reduces total drillout time and costs

Applications

- Casing reaming operations

- Liner reaming operations

Overview

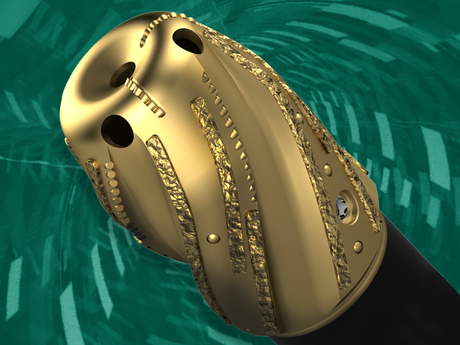

Ream out longer intervals in less time and lower risk with the EZReam™ Casing and liner reaming shoe from Baker Hughes. Our heavy-duty casing/liner shoe lets you reach total depth (TD) through the most challenging hole sections, even severely compromised boreholes.

Improve reaming efficiency and reduce drillout risks

The EZReam technology features a durable tungsten and polycrystalline diamond compact (PDC) cutting structure for faster reaming speeds. The tool’s 360-degree gauge offers added stability to further improve reaming efficiency. The tool is also undersized to promote a smooth transition of the liner through the predrilled hole.

And as the industry’s first steel reaming shoe to offer a secondary bypass port, the EZReam technology lets you continue normal circulation or cementing, even in the event of nozzle plugging.

Once reaming is complete, the tool is drillable with a standard PDC or roller cone, in both onshore and offshore applications.

Some reamer shoes might leave an undrilled portion of the nose downhole, which could damage the next bit or BHA. The EZReam technology’s concave profile drills out from the center to the shoulder, thus eliminating this risk. This patented profile, coupled with unique material properties, enable faster, more reliable drillouts than competitive designs.

Contact us today to learn how the EZReam technology can improve the efficiency and economics of your reaming operations.