Overview

With a portfolio that spans from Downstream to Upstream, we have thousands of parts produced to provide next-level innovation for our customers. We are completely re-thinking the way a tool is shaped and manufactured by leveraging Additive Manufacturing.

By utilizing the latest machines, software, and design practices, Baker Hughes can improve on multiple tools to bring in innovative ways to convert existing technologies to market-leading solutions. In-house we have access to the latest simulation, setup, and CAD software’s to meet customer needs.

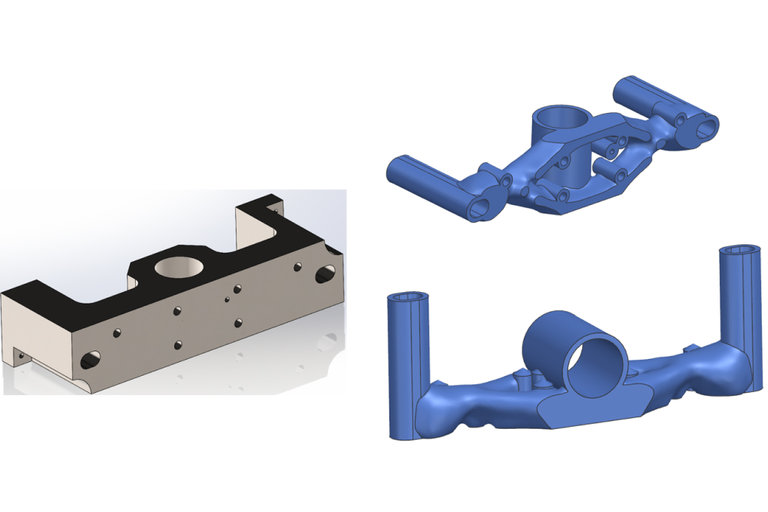

Topology Optimization

Used in multiple parts to reduce weight, material and still meet the strength and load conditions required for the tool to perform.

Performance Engineering

Utilizing state-of-the-art inspection techniques (CT, blue light scanning, etc.), at Baker Hughes we can inspect, model, evaluate the performance, and re-engineer some of the most complex components in the industry.

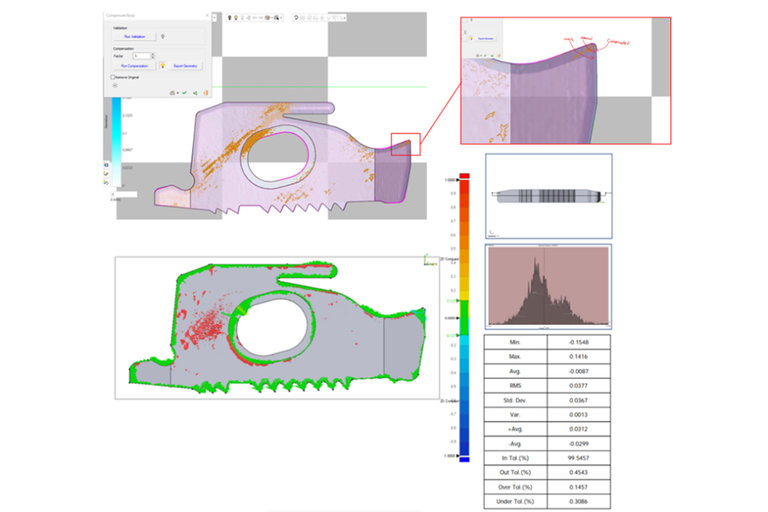

Scan-based Compensation

Sometimes within the additive process distortion can happen and cause parts not to meet inspection or fitment criteria. Within Baker Hughes we can utilize CT/BL scanning to overlay the manufactured component onto the CAD file and generate an inverse model that will meet strict profile and fitment criteria.

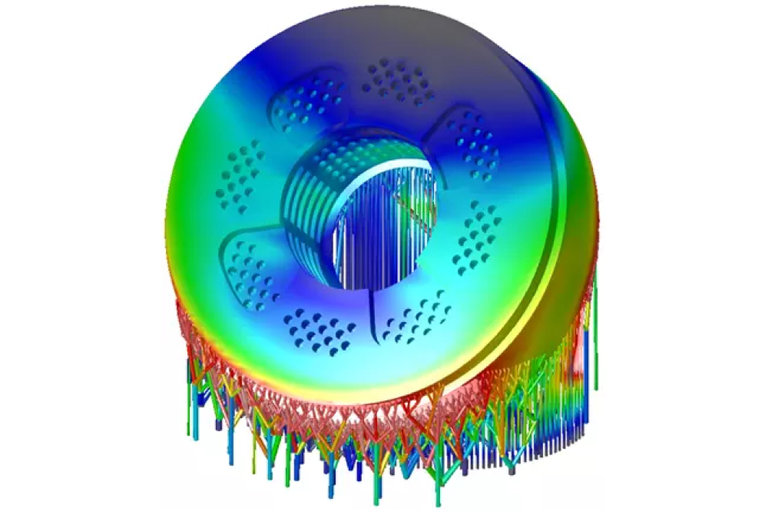

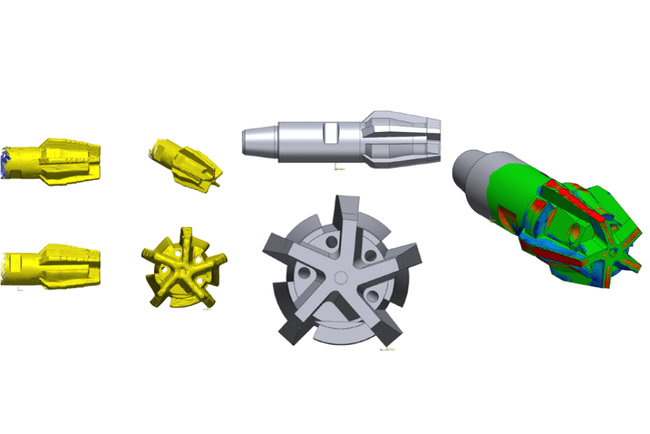

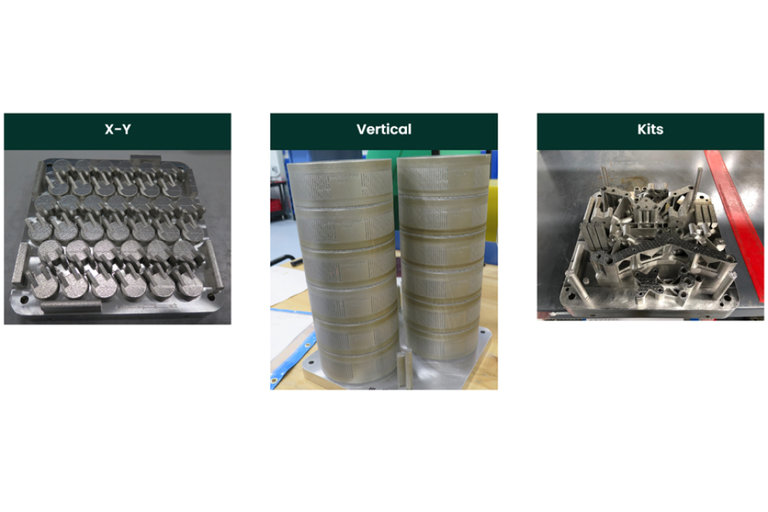

Part Nesting

To optimize production costs within additive manufacturing, Baker Hughes takes advantage of 3 nesting techniques to maximize efficiency and reduce waste.

- X-Y advantages: Pattern complexity, minimize gaps between parts, decrease build height

- Z advantages: Takes advantage of the entire build volume, utilized for parts with consistent cross-sections

- Kitting advantages: Tools with multiple components converted to AM utilize the same build envelope, consistent material results for all components, no excess inventory.