Overview

We build our quality control around having a well-defined Statement of Requirements from our customers. To ensure quality, we perform the following:

- Feedstock qualification testing

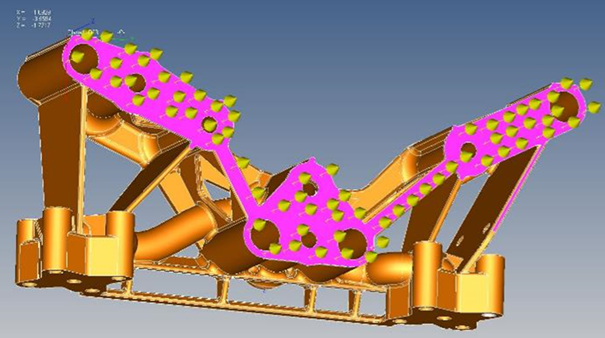

- Machine qualification testing

- Build process qualification.

- Part qualification through First Article inspection and testing

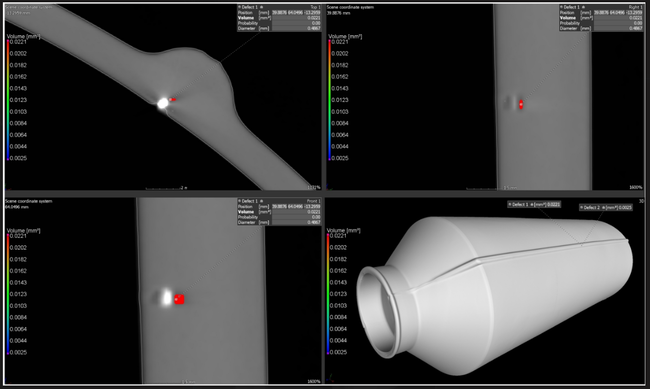

- In-process inspection, including in-process monitoring of our printers using Automatic Defect Recognition algorithms.

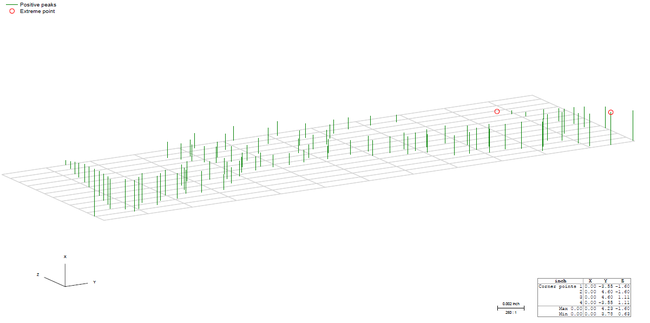

- Final inspection, using calibrated measuring equipment. In-house CT inspection, blue-light scanning and CMM capabilities.

- Builds include test coupons and powder sample capsules for subsequent testing if required. Complete mechanical testing, including hardness, Charpy impact, and tensile testing are available in-house.

We have a robust quality assurance program that includes:

- Having an Approved Supplier List (ASL) for our incoming materials and outside services. The ASL requires that we audit the potential supplier periodically to ensure that they can meet our requirements.

- Review incoming materials to ensure that our internal requirements are met.

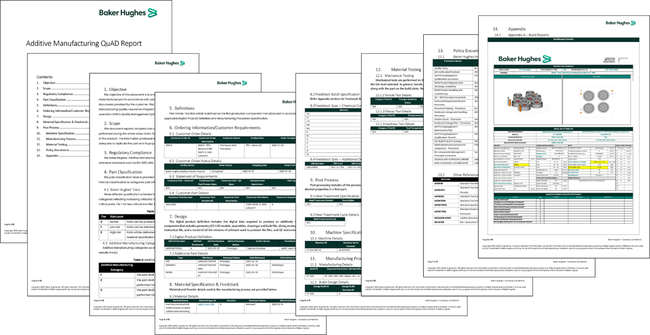

We strive to have our QC built through the entire manufacturing process and monitor everything from feedstock to final inspection. Our state-of-the-art QUAD reporting delivers advanced data to our customers so that every step of the process adheres to the latest industry standards.

We have in use some of the latest in-process monitoring of our DMLM machines that utilize Automatic Ai and machine learning defect recognition algorithms, we also have the latest NDE inspection techniques: CT Scanning, Blue Light and CMM.

Within our organization we can follow the industry standards such as API 20S, API 20T, and others.

CT Scanning

CMM