More than ever before, you can’t let your frac plugs stand between you and first oil. You need frac plug removal solutions that remove every plug—even those set deepest into the lateral—as reliably and cost effectively as possible.

A proven milling solution

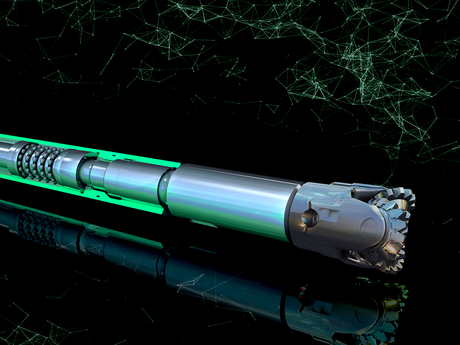

The Baker Hughes Versa-Drive™ plug milling service is engineered to deliver the solution you need. A bottomhole assembly optimized for extreme milling in extended lateral, unconventional wells, the Versa-Drive plug milling service incorporates several tools that optimize your every milling operation.

- The Vanguard™ plug bit is the only bit in the industry specifically designed for extended-reach plug milling applications. Combining self-sharpening teeth, increased tooth count, and proprietary bearing technology, the Vanguard plug bit consistently delivers efficient, reliable single-trip mill outs.

- The CIRCA Real-Time (RT) coiled tubing modeling software enhances safety and efficiency when deploying the Versa-Drive plug milling service on coiled tubing. The software seamlessly connects pre-job analysis with real-world variables to update simulations and ensure greater certainty of success.

- Operational support through stringent quality control, reliable execution, and powerful analytics software helps ensure an optimized milling run every single time.

Taken together, these tools ensure that Versa-Drive plug milling service delivers unsurpassed milling efficiency. In the field, the service consistently mills out more than 50 composite frac plugs in a single trip, with mill out times of just minutes per plug, zero motor stalls and short trips, and rig time savings of 24 hours or more.

Contact us to learn more about the Versa-Drive plug milling service and how it can streamline your milling operations.