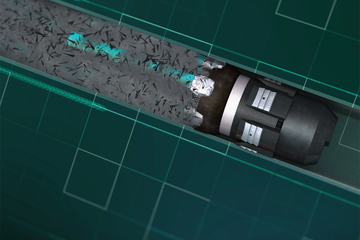

When faced with a long lateral and multiple stages in your plug and perf operation, you need a thru-tubing milling provider that can get to the toe of the well, on time and on plan. Baker Hughes's extended-reach milling capabilities are second-to-none in the industry.

We offer a full range of milling tools and techniques for through-tubing milling intervention. Whether you have loose junk in your well (bit cones, tong dies, packers, etc.) or stuck pipe, we can get your well back on line safely and efficiently.

We have developed advanced milling technology cutting structures that dramatically shorten milling time based on enhanced wear rate, increased impact resistance, and superior cutting edges. The insert geometry, surface treatments, and specialized alloys are custom-engineered to assure successful operations in your specific circumstances. In cases involving extremely hard materials or formations, polycrystalline diamond compact (PDC) or surface-set diamonds may be required.

Our ability to source the right milling tool for the job — coupled with our expertise — can get your plug-and-perf wells on production reliably, and can solve obstruction problems safely and predictably. At the end of the day, you just want that coiled tubing unit in and out as quickly as possible so you can get to production. We are the service provider that can meet that expectation.

Contact your local Baker Hughes representative to choose the right thru-tubing milling tools that can get to the toe, on time and within budget.