Highlights

Highlights

Benefits

- Maximize perforations in high-strength reservoir rock

- Reliably perforate in conditions up to 35,000 psi and 470°F (243°C)

- Ensure accurate, lower applied firing pressures in ultra-deep wells

Applications

- Deepwater operations

- Ultra high-pressure/high-temperature (HP/HT) environments

- Hard rock formations and Critical, complex well designs

OVerview

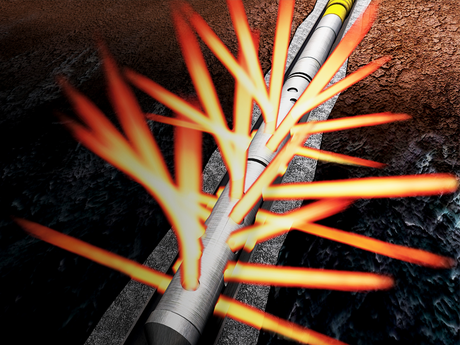

Tap into deeper, hotter, and higher pressure reservoirs with the Baker Hughes UltraConnect™ 35K HPHT perforating system. Engineered for safety and reliability, the system delivers consistent and efficient perforations in wellbores with pressures as high as 35,000 psi (2,413 bar) and temperatures up to 470°F (243°C).

Customized solutions for extreme perforating environments

As you drill increasingly deeper wells, you need tools that perform consistently under challenging high-pressure/high-temperature (HP/HT) conditions. The UltraConnect perforating system was designed to withstand your deepest and hottest wells, and to deliver effective completions that maximize your production potential.

Engineered with field-proven reliability recognized by operators around the world, the UltraConnect perforating system is an integral part of the Baker Hughes line of tubing-conveyed perforating systems and tools.

Regardless of your HP/HT environment, the system can be customized to deliver the performance and efficiency you require. Combining the UltraConnect perforating system with our DeepConnect™ perforating charges, you’re assured optimal perforating depth and spacing in hard-rock environments and when firing through heavy, high-grade casing.

And by incorporating the Baker Hughes Model D™ and Model RD™ pressure firing heads into the UltraConnect system, you’ll gain further perforating efficiency. Featuring precision rupture discs instead of shear pins, these sleek firing systems deliver more accurate and lower applied firing pressures, which is critical in your ultra-deep wells. These firing systems have been tested and validated in accordance with API RP-67 Recommended Procedures for Oilfield Explosives Safety and are among the safest and most reliable in the industry.

Assured execution through careful planning

Even before the perforating system enters the well, we work with you to ensure a seamless perforation job. This begins by modeling gun shock and dynamic underbalance effects with the Baker Hughes PulsFrac™ software. The resulting model output helps ensure that we develop and execute completions plans using the UltraConnect perforating system to maximize your reservoir’s connection with the wellbore—safely and efficiently.

Our preplanning also includes extensive testing that is carried out under conditions that mimic your actual downhole environment—giving you greater confidence in a reliable perforating plan that minimizes unwanted surprises and delays.

Don’t let the challenges of ultra-HP/HT wells discourage you from developing difficult reservoirs. Through disciplined engineering, thorough testing, pre-operational modeling, and exacting execution, the UltraConnect 35 K HPHT perforating system helps reduce risks, while opening access to hydrocarbon reserves that were previously out of reach.

Contact us today to learn how the UltraConnect 35K HPHT perforating system can help you reach new depths in your most complex and demanding wells.