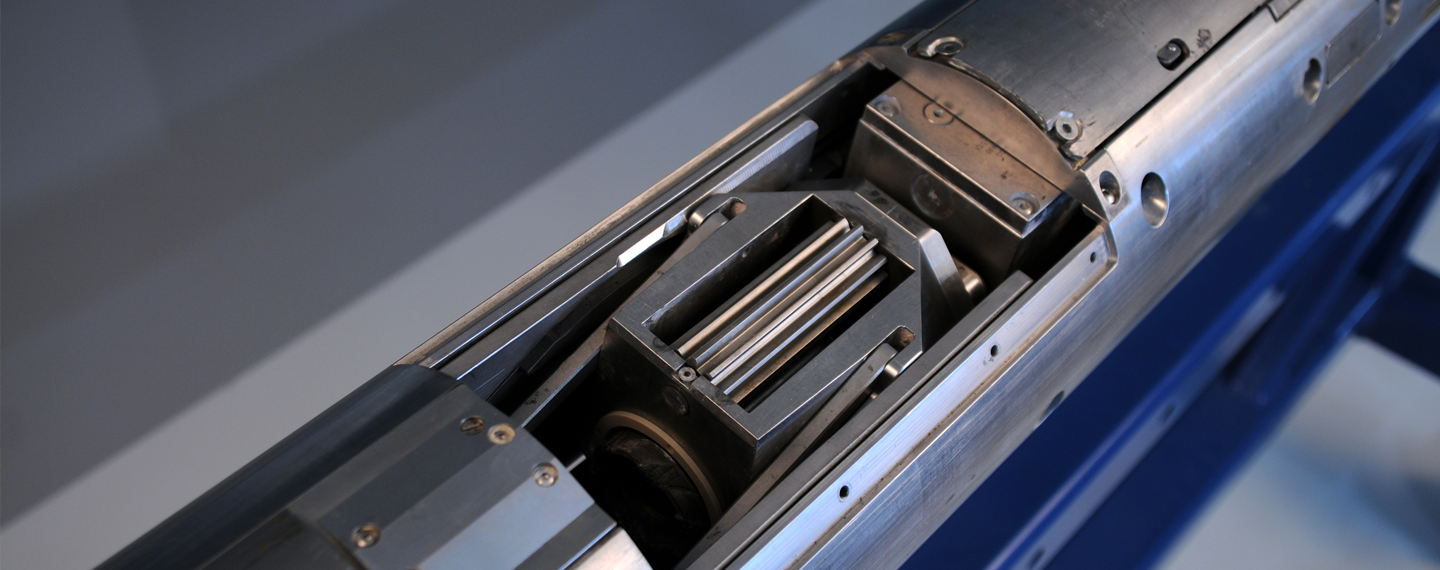

When you’re not able to acquire a conventional core, Sidewall Coring Services from Baker Hughes provide a proven alternative. Our services, built on the backbone of our PowerCOR™ Service sidewall coring technology, give you large-diameter, high-quality cores for sharper measurements of pore volume-dependent parameters.

Full-spectrum core sampling and analysis

Acquire uniformly sized sidewall cores under a wide range of reservoir conditions, including complex reservoirs with varying formations and borehole orientations and high pressure/high temperature formations.

You gain a clearer picture of your reservoir with core measurements that include:

- Geochemistry and geomechanics

- Reservoir geology and petrology

- Porosity and relative permeability

- Wettability and water saturation

- Capillary pressure

- Source rock and hydrocarbon characterization

Proven benefits

- Reduce your coring time. Achieve coring speeds up to three times faster than traditional rotary coring tools with direct-drive electric motors that provide more horsepower to the bit.

- Improve your efficiency downhole. Retrieve up to 60 core samples in just one run, minimizing costs and non-productive time.

- Analyze with greater accuracy. Improve the accuracy of your core analysis with large-diameter samples that provide more than twice the pore volume per unit length compared to conventional rotary coring services.

- Achieve real-time control. Monitor your coring operation as it progresses, with a graphical user interface at surface that helps you control the process for maximum efficiency.

- Improve your reservoir development planning. Capture high-quality cores to sharpen your reserves estimates and guide your long-term completion and production systems designs.

Contact us to learn how our sidewall coring services can help you optimize your core sampling in complex formations.