Highlights

Digital twins of the wellbore construction process facilitate timely, automated alarms for avoidance of costly NPT events.

- Openhole pressure-regime monitoring

- Swab/surge NPT protection

- Reduced personnel risks

Automation of legacy and repetitive manual processes enables incremental KPI improvements for drilling-execution tasks.

- Improved hole cleaning

- Optimized tripping speeds

- Automatic steering and reservoir navigation

Automating well construction enables superior operational execution and reliable financial planning.

- Increased gross rate of penetration

- Fewer stuck-pipe incidents

- Significantly reduced NPT and ILT

Digitalization is rapidly enabling comprehensive, real-time automation of drilling, with benefits from safety to productivity. But reducing human intervention to a minimum requires the simultaneous and automatic control of a range of drilling sub-systems.

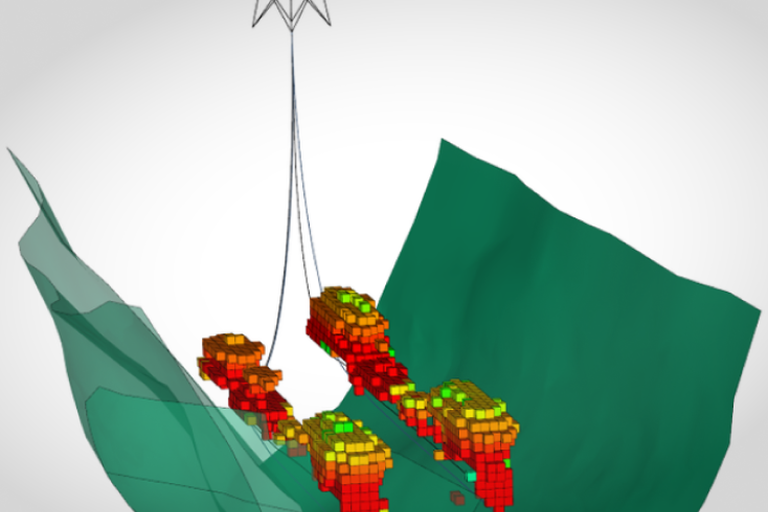

The i-Trak™ drilling automation services incorporate all components within the drilling process, from early planning to execution to knowledge management. We close the loop between surface and downhole data, enabling fully automated trajectory drilling using our industry-leading rotary steerable services. At the same time, our suite of applications analyzes wellbore hydraulics and static loads, and tracks drilling dynamics in real time. This holistic framework ensures repeatable, safe, and high-quality wellbore delivery—every time.

We can meet any directional drilling target, and, along the way, we will optimize parameters to deliver high penetration rate and low wellbore tortuosity.

Designed with open connectivity standards that work with any system, our automated workflows are built on highly accurate, physics-based models and machine-learning algorithms developed over decades of modeling and drilling around the world.

Powered by artificial intelligence, our systems ‘learn’ formation tendencies during drilling, continuously refining and optimizing the drilling process. You define the degree of control you want. In “advisory” mode, the system recommends actions that require user approval. Alternatively, “closed-loop mode” automatically links parameter changes and instructions to our rotary steerable tools—although our workflows give you the option of intervening at all times.

These capabilities don’t just result in consistent drilling performance, reduced operational risks, and lower well delivery costs. They also enhance remote operations, reducing safety risks while enhancing collaboration, efficiency, and productivity as you move your people away from wellsites.