Highlights

Intuitive, guided workflows simplify learning and optimize efficiency, with standard components for faster, more reliable model setup.

- Select from an extensive drillstring design catalog

- Create and compare multiple solution scenarios

- Track changes and data quality automatically

Our Drilling Engineering application enables collaborative working on shared data sets and integrates seamlessly with other JewelSuiteTM applications.

- Work with common industry formats and standards

- Verify mechanics and hydraulics with one click

- Model any drillstring from a comprehensive catalog

Real-time sensor data update the evergreen drilling physics models as conditions change, enabling reliable risk detection and drilling automation.

- Easily transfer pre-job plan to rigsite for execution

- Update simulations automatically with rigsite data

- Automate drilling processes

Precise pre-job planning is vital for fast, accurate directional drilling. Holistic and coherent cross-discipline planning processes and effective team collaboration are the keys to maximizing the success of a drilling project and eliminating hazardous events and non-productive time.

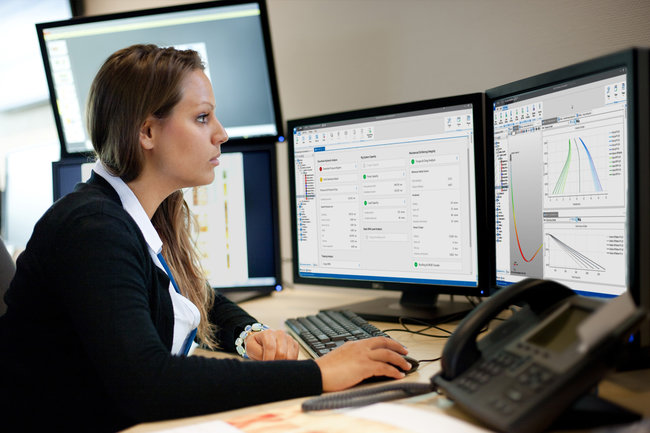

At Baker Hughes, we do it right, every time—empowering drilling and well engineers to optimize drilling results, de-risk operations, and maximize returns on investment. Designed with a user interface for simplified and collaborative workflows, JewelSuite™ Drilling Engineering software is the engine that drives those results, leveraging a uniquely powerful combination of drilling and data expertise.

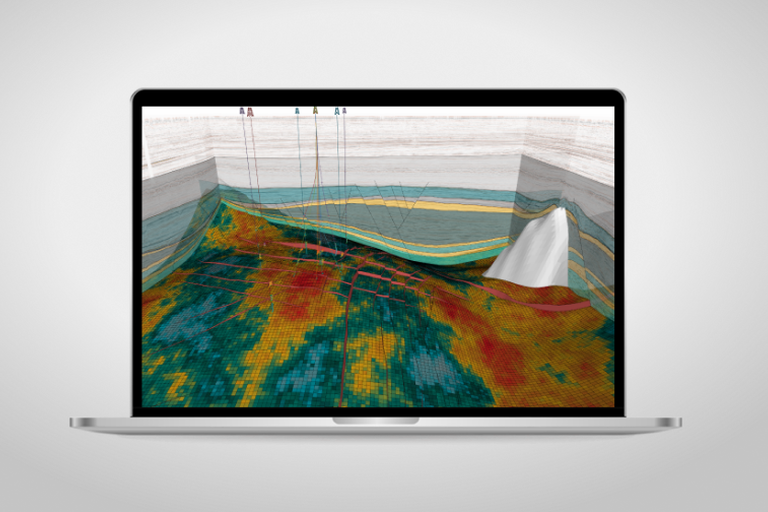

Our highly accurate physics-based simulations leverage extensive offset data to model wellbore geometry and calculate torque, drag, vibration, formation pressures, and other mechanical loads with maximum precision. Drawing on a rich design catalog, we can quickly build advanced digital-twin simulations that streamline workflows for defining drilling environments and plotting well paths. With more than 6,500 Baker Hughes and API standard components in our catalog, all modeled in full detail, we can match equipment to any downhole parameter, from weight on bit to torque to flow rates—ensuring power flows smoothly and efficiently through the drillstring at every stage of drilling.

We’ve also put users at the heart of the Drilling Engineering experience. Easy-to-follow guided workflows accelerate learning and facilitate team collaboration across disciplines and locations. Users can quickly create and compare solution scenarios. Planning teams can easily share data sets. Automated workflows dramatically reduce time spent and eliminate the errors that can creep in through manual data entry. Integrated workflows link up the job planning process, eliminating duplicated data entry across multiple systems, avoiding errors, and reducing downtime. The application automatically tracks changes and data quality, keeping every stakeholder aligned.

During well construction, we continuously refine our models in real time with the latest downhole intelligence on drilling conditions and trends, unlocking the potential of automated drilling and remote operations—and superior use of expert resources.

Integrating seamlessly with other JewelSuite applications, the Drilling Engineering application is both flexible and future proof. Universal data adaptors enable you to integrate subsurface models, formation pressures, and planning elements from a range of other disciplines. And modular architecture means the software can continuously expand to incorporate new simulation capabilities as they are developed by our in-house experts or by third parties.

From the ground up, the JewelSuite Drilling Engineering application is designed by users for users to minimize well-construction risk and deliver optimal performance. Underpinned by fast, efficient, and consistent job planning, it liberates drilling engineers from mechanical software tasks and enables them to focus on developing optimized project outcomes.