Highlights

Highlights

Benefits

- Lower CAPEX vs. conventional systems

- Easy installation and retrofittable

- Compact and efficient

Features

- Smaller size vs. conventional systems

- Less solvent inventory vs. conventional systems

- Solvent agnostic

Applications

- Power generation (e.g., waste-to-energy plants, biomass power plants, etc.)

- Industrial (e.g., cement plants, etc.) and oil and gas (e.g., SMR, FCC, etc.)

- Layout-constrained applications

Featured Video

Featured Video

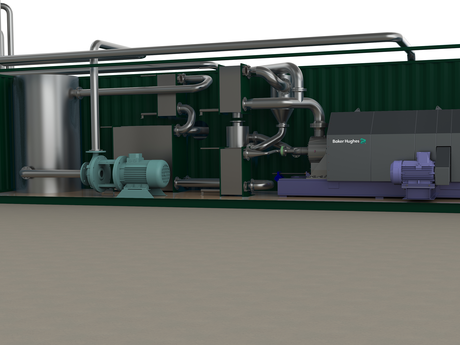

Our Compact Carbon Capture (CCC) technology uses centrifugal forces to distribute the solvent employed for capturing CO2—enabling more effective solvent distribution that enhances mass transfer. Designing a carbon capture plant with CCC will reduce its footprint by up to 75% and require lower capital expenditures when compared to carbon capture plants designed using conventional technologies. Thanks to such size reduction, we can provide a modular and scalable carbon capture unit that can be easily deployed into existing brownfield sites and offshore.

CCC is solvent agnostic and can be employed with highly viscous solvents. It has achieved a technology readiness level 4 according to the H2020 definition.