How do I carry out on-stream inspection?

On-stream inspection can be carried out on

pipes, valves, vessels, and distillation

columns while in operation, in order to establish the degree of deterioration of the

system either the projection or the tangential

technique can be used. Since the introduction of digital radiography, the CR-method

using storage phosphorplates, is increasingly

becoming an alternative for traditional film

in case of on-stream exposures, see chapter

16. The main advantage being that it reduces

the exposure time by a factor of 5 to 10, or if

lower energies (Iridium192 instead of

Cobalt60) can be applied it results in a reduced safety area, which is very attractive in

cramped spaces and personnel nearby e.g. on

offshore platforms.

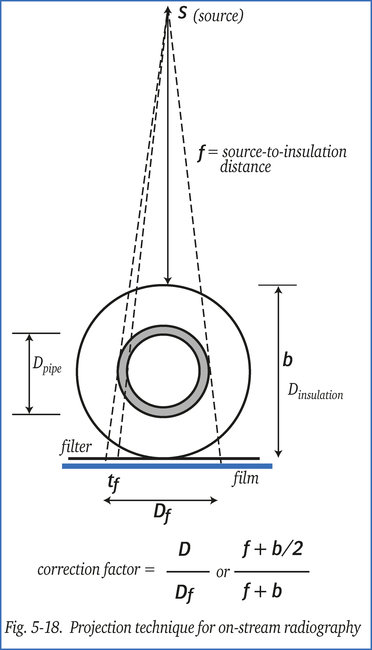

Projection technique

The projection technique is most commonly

used. With this technique the two walls are

projected on film simultaneously, as shown in

figure 5-18. The image projected is larger than the actual object dimensions. It is important

to know the degree of magnification so as to be able to determine the true wall thickness.

If both walls of the pipe are projected on the film, it is straight forward to establish the correction factor, which is the true diameter (D) divided by the radiographic diameter Df .

This method should be used as much as possible.

With the projection technique, the source is placed at a certain distance from the pipe.

At a film-to-focus distance of 3 x Dinsulation and a source size of 3 mm, image quality requirement A of EN 1435 is met.

The actual pipe wall thickness (t) is equal to the

image on film (tf ) multiplied by the correction

factor (see fig. 5-18).

Most common is on-stream radiography of

insulated pipes, for which half the insulated

diameter determines the sharpness. In on-stream radiography it is important to know the

direction of the product flow, so that a existence of localised wall thickness reduction can be

better deduced. Films of 30 x 40 cm are generally used for pipe diameters up to 250 mm.

Larger diameters require more films.

Tangential technique

In the pipe diameter range of 250 to 400 mm

the tangential technique, as shown in figure 6-

18 is sometimes applied. Only one wall is pro-

jected. The perpendicular projection produces

a sharper image. This allows a shorter focus-to-film distance, and consequently a shorter expo-

sure time. Generally, a focus-to-film distance

of 2.5 x Dinsulation is chosen.

The correction factor would then be:

(2.5 x Dinsulation -0.5 x Dinsulation) / 2.5 x Dinsulation = 0.8.

Selection of source, screens and filters

The graph in figure 7-18 indicates which radioactive source is the most suitable, depending

on pipe diameter and wall thickness. The quality of the radiograph can be optimised by

applying filters and screens, see table 1-18.

Exposure time

Obviously different exposure times are required for gas filled or liquid filled pipelines.

Below are a few examples.

For gas filled pipelines:

Depending on diameter and wall thickness : Iridium192 or Cobalt60, see figure 7-18

Focus-to-film distance : minimum 3 x Dinsulation

Irradiated thickness : 2 x nominal wall thickness

Film type : minimum C5 (EN584-1)

Film density : minimum 2.5 in the centre of the pipe projection

For liquid filled pipelines:

Depending on the diameter, wall thickness : Iridium192 or Cobalt60

Focus-to-film distance : minimum 3 x Dinsulation

Irradiated thickness : 2 x nominal wall thickness plus steel

equivalent of the pipe content

Film type : minimum C5 (EN584-1)

Film density : minimum 2.5 in the centre of the pipe projection

The steel equivalent of the pipe content is determined as follows:

(specific density in kg/m3 of content) / (specific density in kg/m3 of steel) x internal diameter

= .... mm of steel

Density of steel = 7.800 kg/m3

Density of content (oil and aqueous liquids) = 800 to 1.000 kg/m3

Notes:

- In the most commonly used insulation materials absorption is negligible.

- The long exposure times cause over-irradiation at the edge of the pipe. As a result the pipe wall shows up ‘thinner’.

Figure 8-18 shows preparations for on-stream radiography being made. The end piece for

the gamma-source is positioned above the pipe, while the flat film cassette is placed below.

Figure 9-18 shows an on-stream radiograph of a pipe with severe pitting corrosion.

Since the introduction of digital radiography the CR-method, using storage fosforplates, is

rapidly becoming an alternative for traditional film. The main advantage being that it redu-

ces the exposure time by a factor of up to 10, or if weaker sources can be applied a reduced

safety area which is very attractive in cramped spaces e.g. offshore platforms, see the sections about Digital Radiography (e.g. this section)