Krautkrämer HydraStar

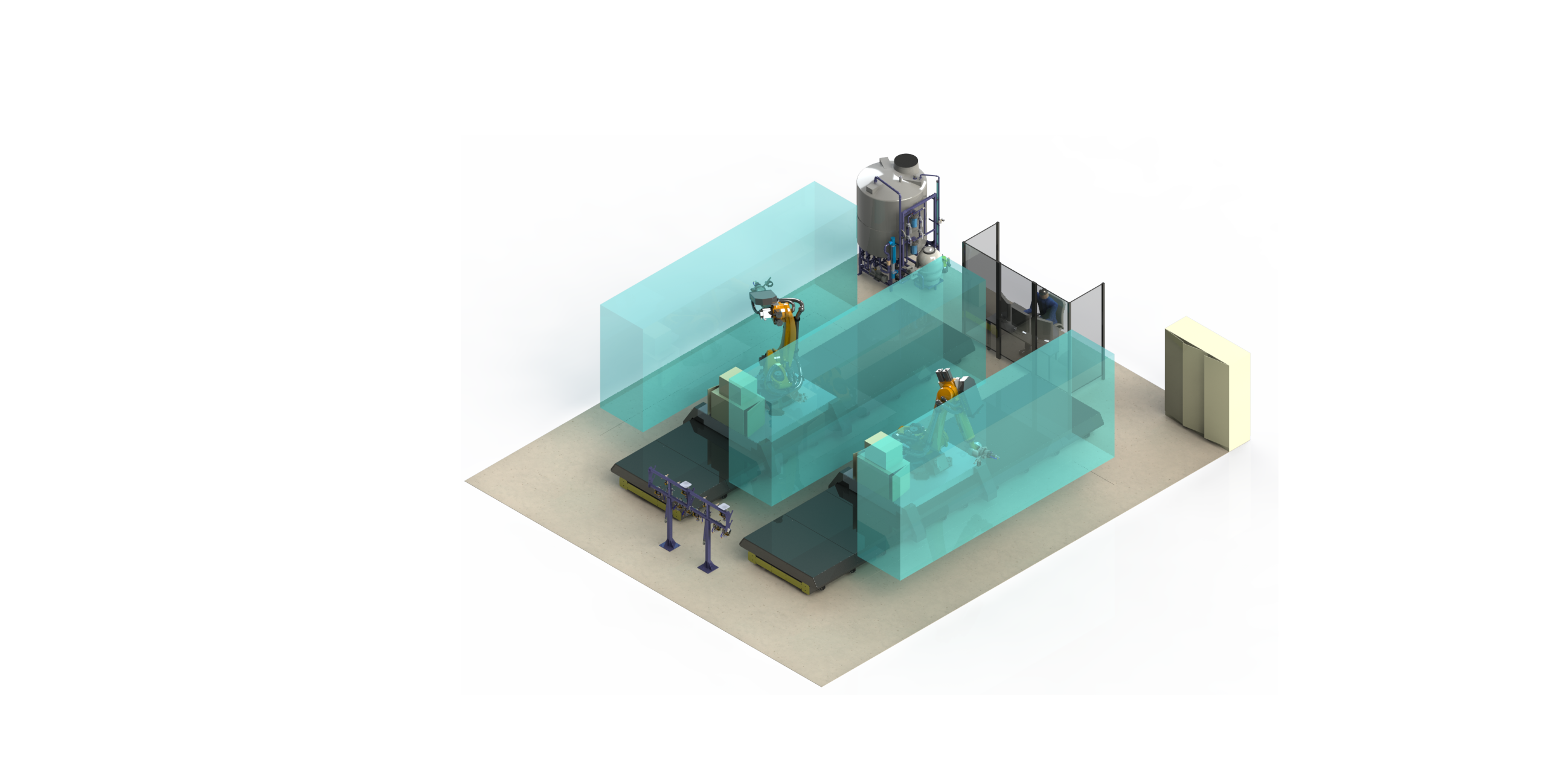

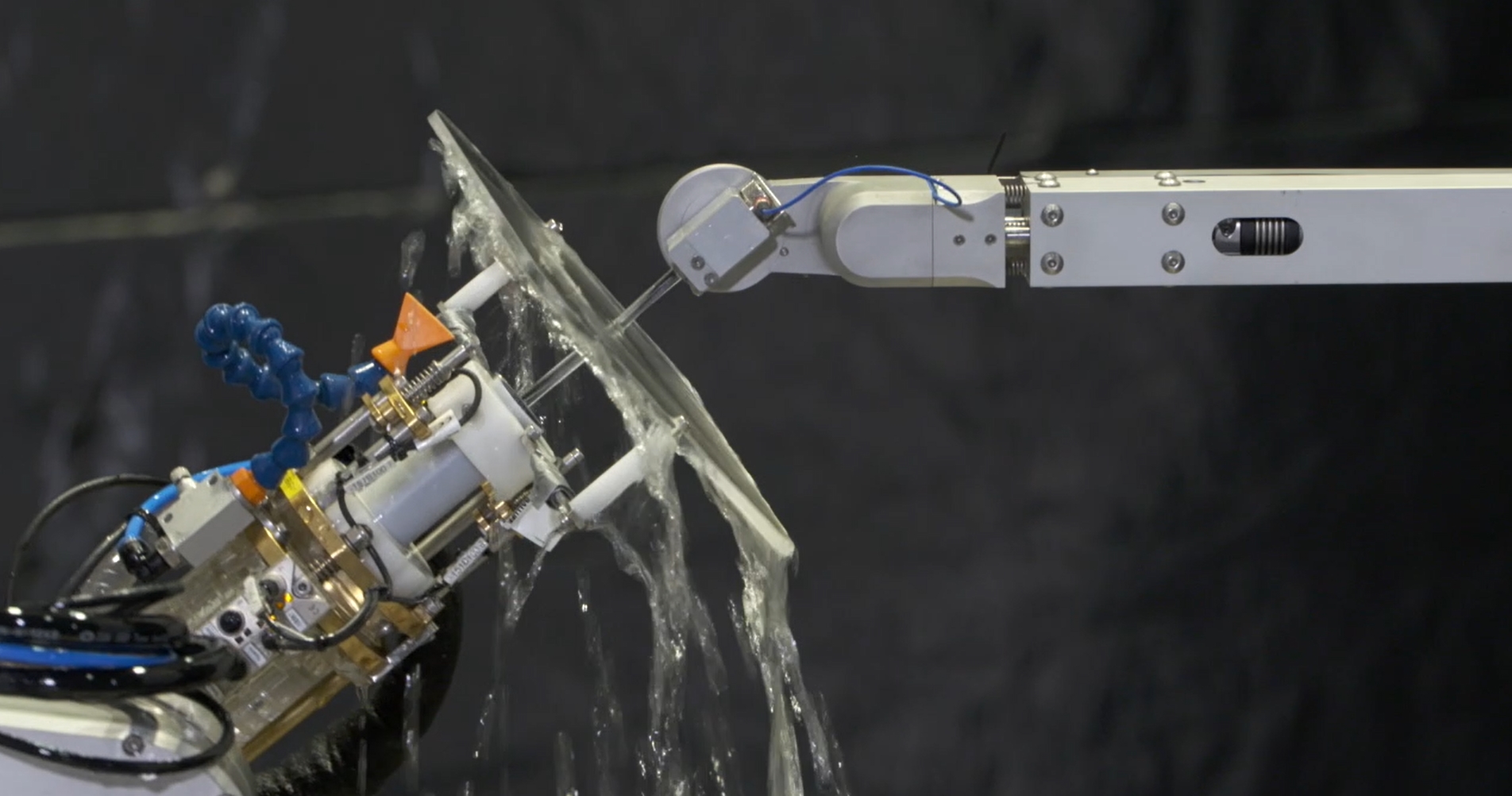

Krautkrämer HydraStar is a complete turnkey solution platform available in single and dual robot configurations with optional linear slides and turntables to inspect a wide variety of component geometries.

The use of composite materials has surged across industries over the past several years. Composites are now used in a variety of safety-critical parts from aircraft wing sections to complex 3D components. Waygate Technologies designs composite inspection systems to meet demanding inspection requirements at very high throughput rates. So, you can inspect parts at speeds that keep up with your industry.

Highlights

Benefits

- Leading accuracy values

- Broadest application flexibility

- 40+ years' experience in composite inspection

- Improved serviceability and global support

Features

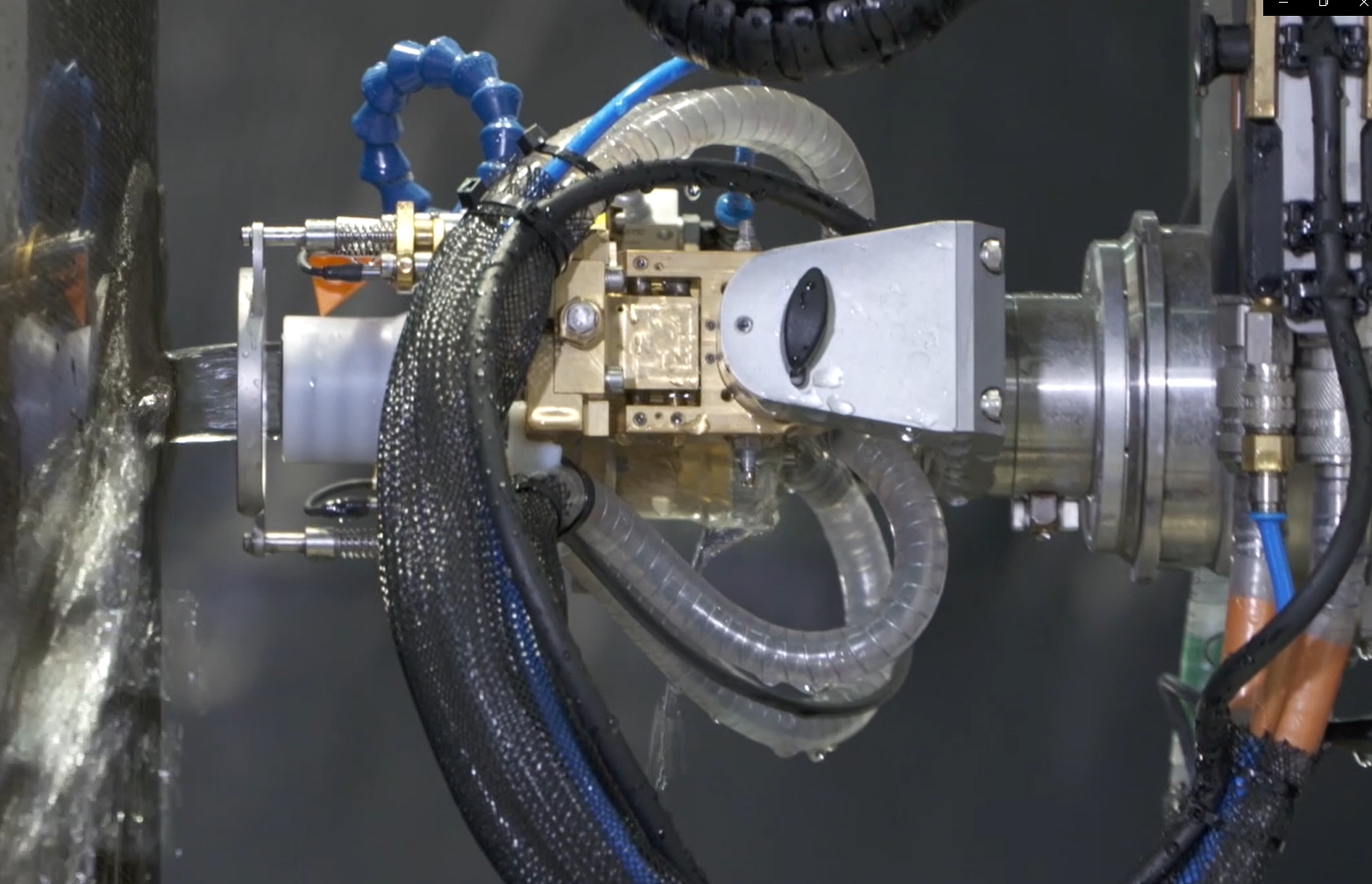

- Adaptive Accuracy Control (AAC) to measure deviations between cooperating robots and compensate them

- The accuracy of cooperating robots can be improved to <0,2mm

- Equipped with standardized robots relying on a global service and support structure

Applications

- Configuration flexibility to match your precise application

- Find details below

HydraStar comes with the new adaptive accuracy control (AAC) feature to measure deviations between cooperating robots dynamically and compensate them to achieve the best possible tool alignment for Through Transmission Testing. With the patented AAC feature the accuracy of cooperating robots can be improved to <0,2mm.

Krautkrämer HydraStar is equipped with standardized robots relying on a global service and support structure. To reduce downtimes and operational costs, operators can use its patented accuracy compensation feature to realign the system without the need of external tools or special expert knowhow. In addition, UT instrument calibration, remote service agreements (RSA) and supporting service agreements (SSA) are available.

A multitude of modular UT electronics, from high-precision single-channel applications with outstanding dynamic range performance, to external high-power transmitters, to multi-channel phased array packages for critical application needs and highest test speed requirements complement the Krautkrämer HydraStar:

Our extensive team of specialists support our customers around the globe. Our experts also examine special needs, solve specific challenges, and develop customized solutions and set ups with our dual robot demo system in our application laboratory.

HydraStar dual configurationconsists of two robots mounted on linear slides that can operate in our patented synchronous motion for TTU inspection or be controlled independently for Pulse Echo applications.

HydraStar single configurationconsists of one robot mounted in either a fixed location with a turntable or mounted on a linear slide employing a yoke tool for TTU inspection and a complete set of Pulse Echo application tools.

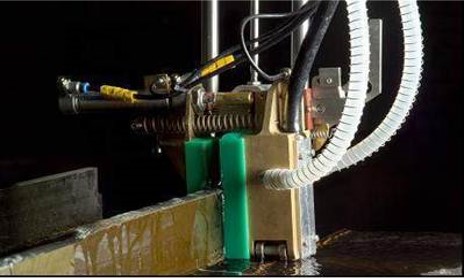

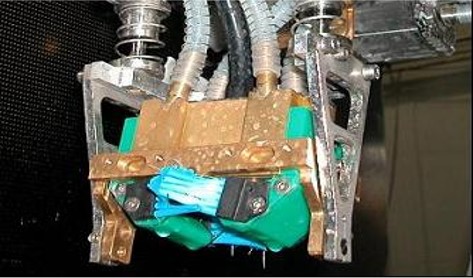

Dual frequency inspection in a single pass using Waygate Technologies annular ultrasonic transducer design, achieving twice the throughput of conventional single channel squirters.

Waygate Technologies patented phased array squirters provide up to a 15 mm wide scan area in a single pass.

Provides Pulse Echo inspection with up to a 86 mm track width in a single pass. Geometrical variations within the test part are compensated by Waygate Technologies patented RPCA (Reverse Phasing Contour Adaptation) method.

Inspects concave (inner) radii in a single scan track/path. Geometrical variations within the test part are compensated by Waygate Technologies patented RPCA (Reverse Phasing Contour Adaptation) method.

Inspects convex (outer) radii in a single scan track/path. Geometrical variations within the test part are compensated by Waygate Technologies patented RPCA (Reverse Phasing Contour Adaptation) method.

Allows access to narrow passages to facilitate TTU inspection with an additional rotational axis at the end of the extender and miniature squirter nozzle.

Provides Pulse Echo inspection of the stringer web of T-shaped stringers or variations of it typically in a single pass at 100% coverage using a phased array probe with up to 128 elements.