The medical technology industry faces multilateral inspection challenges when manufacturing products that have a direct impact on the quality of many people’s lives. Product safety and reliability are crucial. High and stringent quality and safety standards have to be met. At the same time, the technology applied in many devices is ever more complex, implants are becoming smaller and high-tech electronic components are increasingly deployed. Product development cycles and production processes on the other hand continue to speed up.

We offer world leading CT-image quality to facilitate your full-cycle quality control

Detect structural defects in electronic or mechanical parts, orthopedic implants and dental applications, or need high precision metrology for the inspection of part dimensions

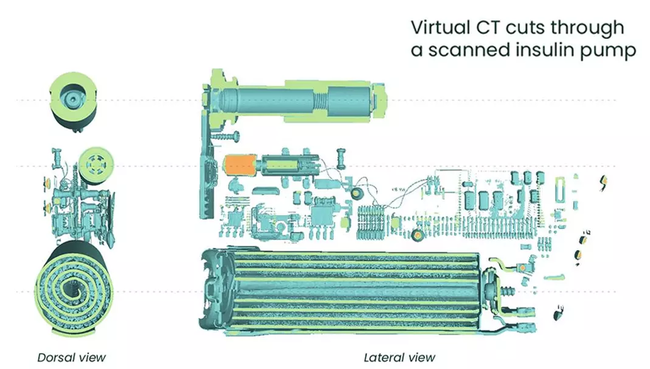

From pacemakers and other battery powered implants like nerve stimulators or cochlear implants, to orthophedic implants, dental replacements & brackets, catheters, surgical staples to hearing aids and insulin pumps

Quality control management all over the world still largely relies on manual workflows of visual inspection, with paper-based documentation that is in urgent need of better regulation and traceability

Safeguard 100% quality control while facilitating faster product design, more productivity and lower costs, and meet the challenges of OEMs and suppliers.

From pacemakers to orthophedic implants, dental replacements and brackets, catheters, surgical staples to hearing aids and insulin pumps