Highlights

Highlights

Benefits

- Up to two years faster from LNG project inception to operation — including significantly fewer on-site personnel and less site time

- Lower engineering and construction costs for LNG facilities with fully tested plug-and-play modules delivered to site

- Less carbon dioxide, resulting in lower emissions for the entire LNG plant

Features

- Compact liquefaction modules (0.8 up to 2 MTPA) can be added incrementally to increase capacity while managing financial exposure

- Power island can be designed for an eLNG plant - lowering emissions, adding flexibility and maximizing operability

Applications

- Onshore and offshore LNG

- Small to medium scale resources

- Ideal for remote locations

Featured Video

Overview

Overview

Many LNG reserves around the world (both accessible and remote) are too small to be economically viable with the traditional large-scale, stick-built approach to engineering and construction of LNG projects.

Thanks to pre-constructed turnkey LNG modules, NMBL™ minimizes risks and provide better control over the project execution phase.

With NMBL™ modules, LNG production becomes easier and scalable. Our modules can be quickly commissioned and scaled up by one or more at a time— to meet any gas demand.

Liquefaction module

Our NMBL™ is designed for low weight, compact footprint, fast integration at site. In the 1 MTPA production capacity range, the liquefaction process module weights ~3,000 tons and has a footprint of ~1,000 m2.

Driven by an electric moto-compressor, the liquefaction process produces zero emissions during the operational phase (based on scope 1 and 2).

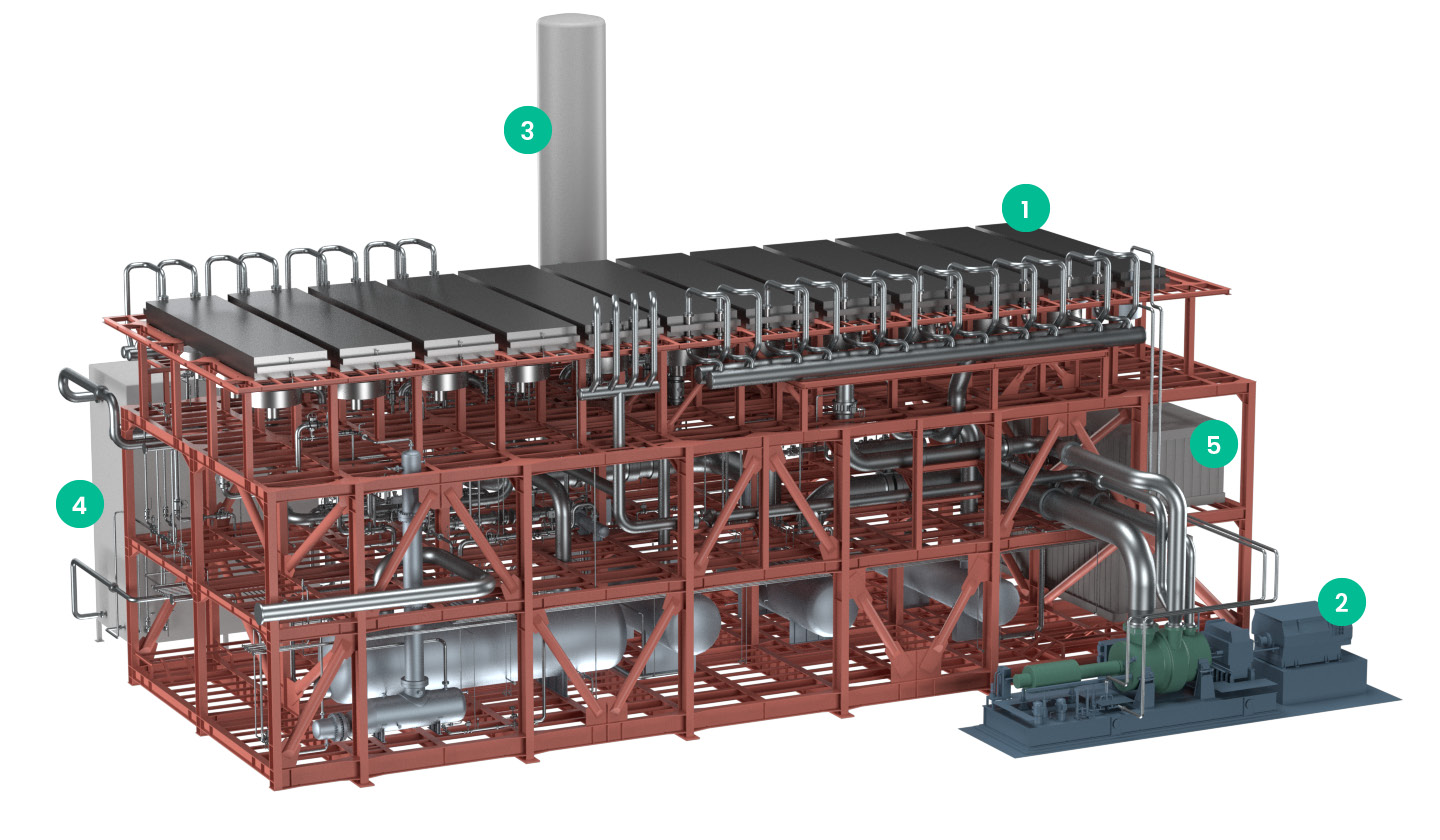

Each NMBL™ train includes:

1. Process module

- Air coolers

- Vessels

- Electrical control cabins

- Separators

- Scrubbers

2. Mixed refrigerant compressor

- Based on Baker Hughes leading centrifugal compressors technology

- Leveraging powerful electric motors from BRUSH™ Power Generation, 40-75 MW class with common soft start

- Other drivers available, including the light and efficient Aeroderivative Gas Turbines from the LM2500, LM6000 and LM9000 families

3. Surge vessel

- Refrigeration storage

4. Cold box

Brazed Aluminum Heat Exchangers (BAHX)

5. e-room

- Soft starter

Digital native

NMBL™ modules are digitally native, as they can integrate the equipment offering with lifecycle service and software features. Being designed in-house, the liquefaction process leverages Baker Hughes’ expertise to achieve the necessary levels of reliability and availability and to maximize plant production even in off-set conditions.

Power-generation

In addition to the liquefaction train, Baker Hughes can supply the most suitable power island to feed the LNG plant in an efficient and reliable way.

Power blocks can be conceived as multiple LM9000 aeroderivative gas turbines. The LM9000 can work in simple or combined cycle arrangement and can also compensate intermittent renewable sources supplying the LNG plant. When in combined cycle, LM9000s are equipped with steam recovery heat generators and one or more steam turbines from the SC product line: in this way, a combined heat and power plant solution helps lower the CO2 footprint of the LNG facility.

Low-risk construction and installation

The liquefaction modules are all fully constructed, tested, and commissioned at our yard in Avenza, Italy, before shipping to your project site. Upon arrival, final installation is 15-20% faster than traditional stick-built projects, and requires 60% significantly less on-site personnel. These factors, along with simplified interconnections and civil works, dramatically reduce plant project costs.

The pre-tested, modular approach minimizes site non-conformities, enables exact replication from one module to the next, and ensures a predictable schedule with minimized risk.

Our Avenza yard has comprehensive capabilities, including:

- Experience with fabrication of oil and gas modules since the ‘80s

- ~290,000 m2 and expanding

- 2 covered warehouses, 27,000 m2 combined

- 1.5 km from Carrara Port

- 4,000 tons load-out capacity

- 20 erection and testing areas

- Testing for power-generation modules at full speed and full load up to 130 MW

- Testing facilities under development for large LNG mechanical-drive trains at full speed and full load

- Avenza-Massa-Florence proximity enables seamless interaction between all our engineering, construction, and testing resources