Highlights

Benefits

- Saves rig time and costs by reducing two e-line trips to one

- Reduces HSE risk with surface rigging reduced by 50%

- Enhanced reliability with electro-mechanical cutting activated immediately after free pipe determination

- Precisely cuts pipe without the use of ballistics or hazardous chemicals

Features

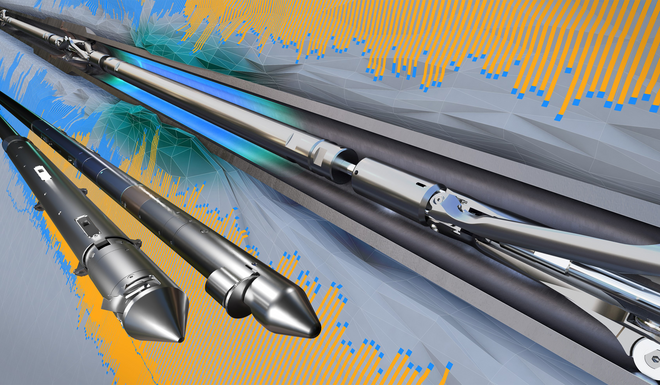

- Industry leading free-pipe detection and electro-mechanical cutting technology in a single trip

- Deployed by PRIME 212 & PRIME 338 tractor and integrated with the PRIME Release Sub System (RSS)

- Easily mobilized inside a peli case via road, sea, or air to the wellsite

Applications

- Drilling pipe recovery

- Well intervention

- Plug & abandonment

Overview

Traditionally, a pipe recovery operation involved identifying the free-pipe depth (diagnosis) of a stuck drilling bottom hole assembly (BHA) or tubular with a dedicated wireline trip in the well. This is then followed by a separate trip for a cutter or back-off (treatment).

Certia Log & Cut, combines two industry leading technologies for pipe recovery, enabling a single-trip, multi-task solution.

Safer operations

Deploying Certia with an electro-mechanical cutter in a single trip removes two surface events from the operational scope (rig down run 1, rig up run 2).

Faster operations

Combining two wireline trips into one can result in a 50% reduction in operational time for the pipe recovery along with a subsequent reduction in carbon emissions.

Well control

Single run pipe recovery operation can half the duration of time the wireline is across the drilling BOP. Once the free-pipe depth has been identified, switching to cutting mode can be done instantly minimizing any risk of stuck depth migrated shallower.

Deployment

The Certia Log & Cut solution is deployed by PRIME 212 and PRIME 338 tractor and integrated with the PRIME Release Sub System (RSS).

Rapid mobilization

Certia Log & Cut solution is easily mobilized inside a pelicase transportable via road, sea, or air to the wellsite.