Highlights

Highlights

Benefits

- Eliminates considerable travel time, cost, and logistics

- Same reliability level as traditional on-site approach

Features

- Full visibility of equipment and test procedures through live video, audio, and secure data displays

- Experienced Field Service Engineers work closely with your team before and after test to ensure highest productivity

- Full technical support for virtual connections

Applications

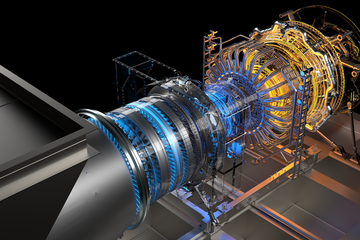

- Full-load, full-speed turbomachinery test

- Power generation

- Mechanical drive

Overview

A string test is a major project milestone performed on the first full set of equipment. It's the only way to replicate and simulate site operating conditions and prove that all the major components function together as they should. A String Test Acceptance Certificate is an important indicator of on-time delivery for the overall project.

The test performs a mechanical running assessment, and measures equipment vibration and bearing temperatures at full speed and full load. Any fit or assembly problems are identified and resolved. Auxiliary and control systems are also calibrated, which minimizes these activities in the field.

Logistically challenging

String tests can take from one day up to several days or weeks to complete. They typically involve face-to-face participation by various customer representatives, inspectors, engineering and project management teams—which often results in well over 30 people present on the test site to verify equipment performance. At the best of times, clearing schedules and making travel plans for all these people is a feat in itself.

The smart solution

Baker Hughes has the digital infrastructure to deliver a reliable, fully remote approach—avoiding the need for anyone to travel to witness a string test. Procedures are performed on equipment located at our testing facilities. We leverage a combination of teleconferencing and virtual-meeting software to enable audio and video interaction across any number locations around the globe.

Our Field Service Engineers use Smart Helmets—a combination of hard hat and various camera, computer vision, and sensor technologies—to let everyone participate in a walkdown of the test equipment. All participants can see and hear each other in real time, and customer engineers have a clear view of all equipment in the package. During the tests, remote participants can also view the live data screens through secure links with our remote monitoring and diagnostics iCenters.