Highlights

Highlights

Benefits

- Quick access to OEM field operation knowledge, eliminating the time and cost of mobilization to site

- Direct contact with multiple experts, including not only field service engineers but also wider engineering teams and suppliers

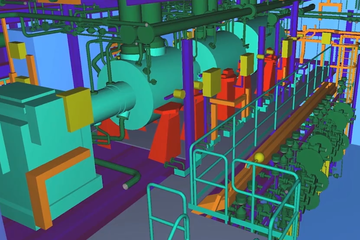

- Open connection to OEM software and tools like augmented reality and smart helmets for real-time retrieval of documents, specifications, and drawing

Features

- Remotely located Field Service Engineers support execution of on-site activities through advanced communications devices

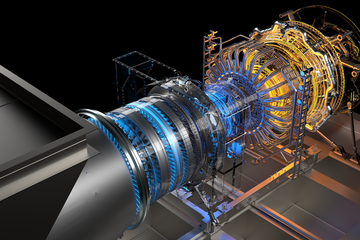

- HMI remote control to start units, implement upgrades, and optimize the combustion system

Applications

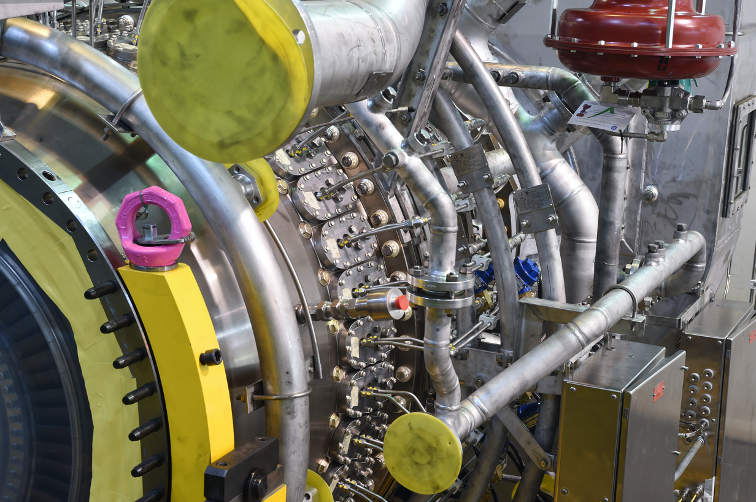

- Planned maintenance execution

- Midstream and downstream oil and gas technical support and service calls

- Upgrade, installation, commissioning, and start-up

Overview

Overview

Our turbomachinery field service teams and maintenance technicians deliver a wide range of remote support for field activities—enabling high first-time fix rates and faster solutions. We eliminate the complex logistics associated with mobilizing engineering personnel to customer sites for maximum customer satisfaction and reduced downtime.

Field execution

- Experienced remote service engineering expert available to support facility crews with installation, outages, troubleshooting, and upgrade activities

- Daily outage report and lessons learned

- Red-flag reviews for execution

- On-demand remote support

Commissioning and start-up

- Instruction for field modifications

- Technical packages for product line installation and commissioning

- Remote execution of loop checks, functional tests, and unit start-up after outage/upgrade/installation

DLE/DLN tuning

- Expert remote optimization of combustion system, requiring only minimally skilled personnel to assist at the site