This case is an excellent example of Baker Hughes collaborating with a global customer to identify a technology solution that drives differentiated value.

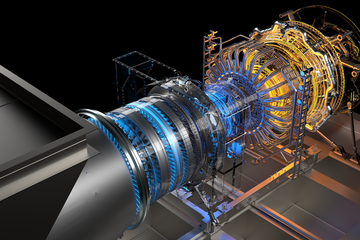

One of ExxonMobil’s LNG facilities uses 13 of our PGT25+G4 gas turbines for liquefaction mechanical drive. These two-shaft machines are well known industry-wide for their high efficiency, reliability, availability, and low environmental impact. But they still need to be inspected every six months. That is, until now.

Challenge

A Level 1 gas turbine inspection is typically performed semi-annually (or at 4,000 fired hours for PGT25/+/G4 machines). It involves the shutdown of critical production trains for borescope inspection of the gas generator and visual checks of the turbine package. The energy industry requires more flexibility on maintenance requirements while maintaining the reliability and the integrity of gas turbines for critical LNG and production assets.

Have a similar challenge?

Solution

Our Dynamic L1 service introduces a condition-based maintenance strategy for aeroderivative gas turbines. It includes software, hardware, upgrades, engineering advisory services, and leverages the extensive domain knowledge and remote connectivity at the Baker Hughes iCenters™ (powered by Cordant™), which monitor over 1,800 critical rotating machines worldwide and covers over 60 LNG projects currently in operation.

Baker Hughes’ Dynamic L1 is designed to extend the turbine inspection interval from 4,000 to 17,500 fired hours—or from six months to approximately two years.

The solution covers all maintenance tasks foreseen by Level 1 inspections, leveraging flange-to-flange OEM residual useful life (RUL) models, diagnostic analytics, and hardware upgrades.

- Functional tests foreseen in L1 are automated without impacts on machine operation

- Maintenance tasks identified as “not required” by analytics and OEM RUL models are deferred

- Any activities identified as mandatory by analytics and models are managed by a periodic report

It continuously monitors machine and auxiliary systems and provides periodic reports for:

- Next L1 estimated date

- Flange-to-flange health status

- Auxiliary-systems health status

- Recommended actions

Benefits

Since 2021, Dynamic L1 has guaranteed the same turbine reliability and performance but with significantly reduced maintenance.

LNG Train 1 has already shifted to a bi-annual interval— avoiding nine days of shutdown and all associated costs.

Following this project’s success, we implemented Dynamic L1 at one of ExxonMobil’s offshore facilities in North America that uses five of our LM2500+ gas turbines for mechanical drive and power generation. Dynamic L1’s capabilities have completely changed the facility’s maintenance philosophy for this equipment, resulting in an innovative new outcome-based service contract to optimize production for the project.

“Supplier performance is fundamental to ExxonMobil’s success. We seek to work with suppliers like Baker Hughes who share our commitment towards delivering value, and we’re delighted to honor the team’s innovative performance.”

Vice President of Global Procurement, ExxonMobil