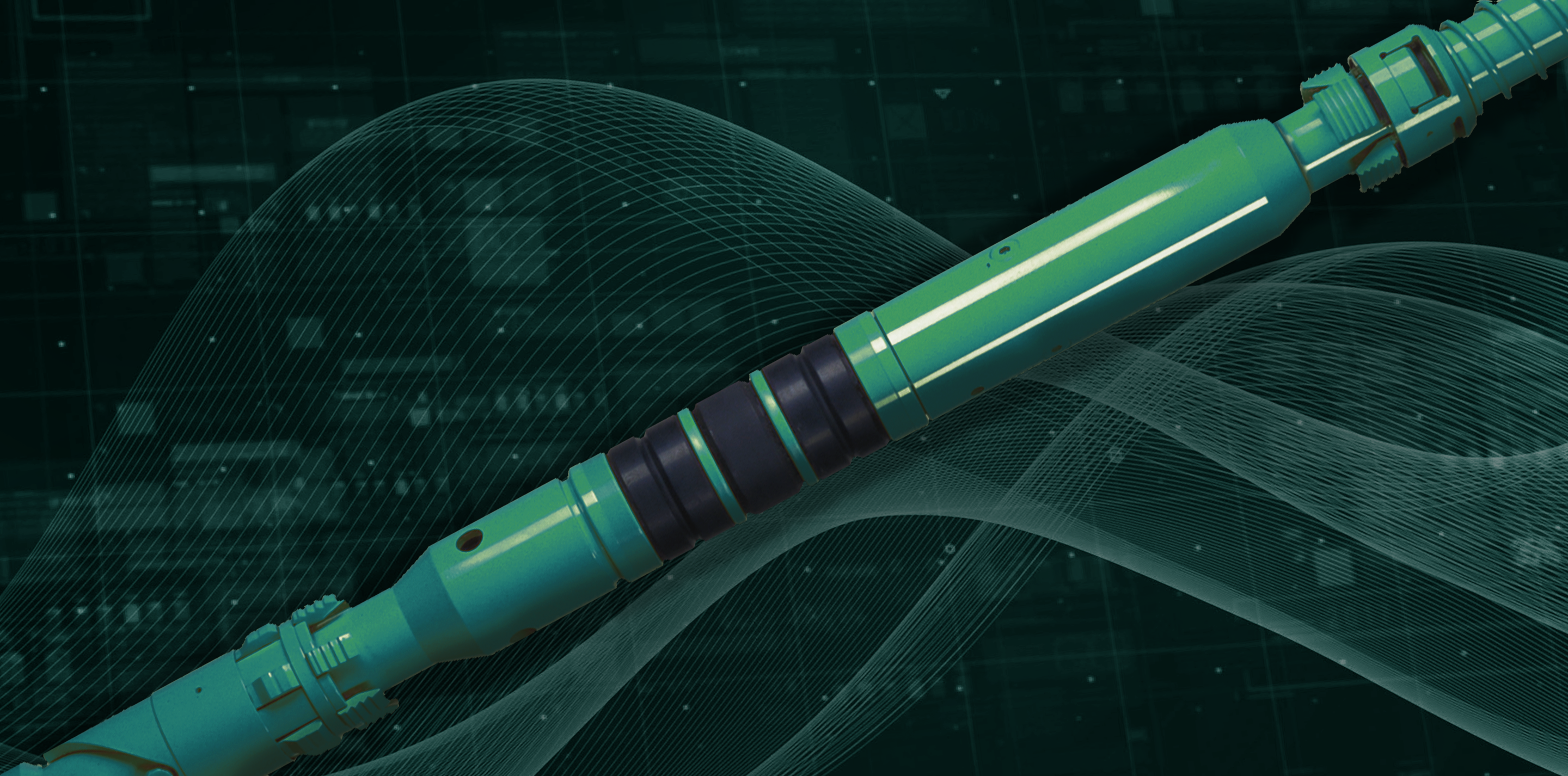

Mechanical- and wireline-set packers from Baker Hughes provide a robust, reliable seal ahead of your perforating, injection, pumping, and production operations.

Get assured isolation and ease of operation with mechanical-set isolation packers. The HORNET™ and S1X™ families of mechanical packers set the standard for high-performance reliability in your thru-tubing fracturing and stimulation operations.

These packers can be effectively landed in tension, compression, or neutral positions, while holding pressure from both above and below. As a result, mechanical-set packers withstand extreme reversals of pressure differential and anchor the tubing against changing tensile loads—while maintaining a seal throughout the operation. And with their ease of operation—a ¼ to the right sets the packer and another ¼ turn to the right releases it—you can easily set, release, move, and reset to treat multiple sections of the well during the same trip.

The WL™ wireline-set packer ensures robust, temporary plugging of your well prior to perforating in underbalance conditions, treating, or fracturing through the casing. WL packers avoid the need to snub tubing in the hole or kill the well. With a wireline- retrievable plug installed in the L-10™ seal nipple profile before deployment, the packer serves as a temporary bridge plug. And when the WL plug is installed above the packer, any sand can be completely washed from the plug’s locking mechanism just before attaching the tubing string to the seal nipple. The plug can then be easily removed to restore well production.

Contact us to learn how mechanical-and wireline-set packers can provide greater flexibility and reliability to your stimulation and production operations.