Highlights

Highlights

Benefits

- Up to 40% efficiency in simple cycle

- Modular exchange philosophy and easy maintenance deliver best-in-class availability and reliability

- Maximized fuel flexibility: can operate on a wide range of liquid and gas fuels

Features

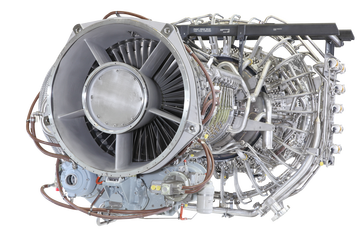

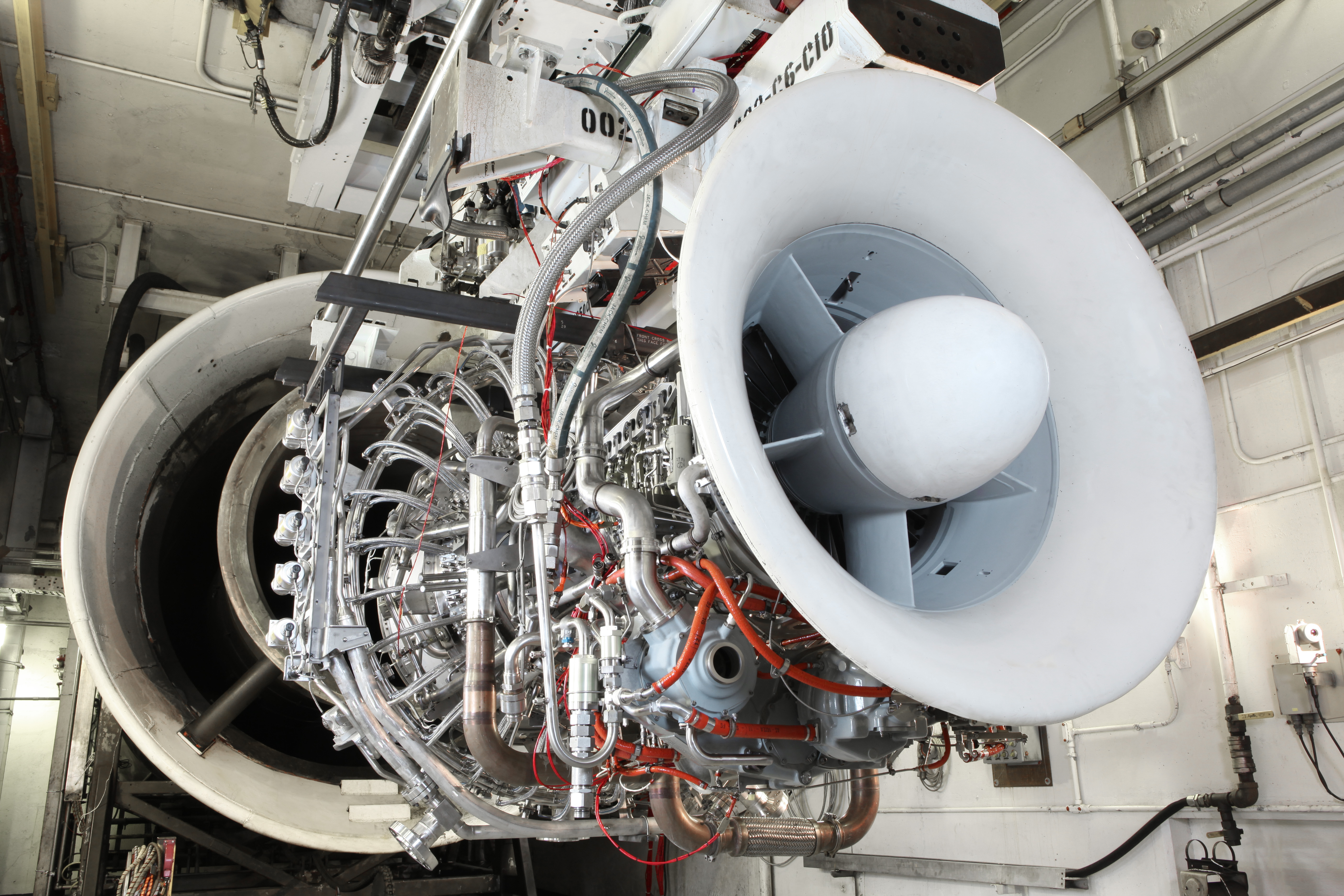

- 17-stage high-pressure axial compressor

- Annular combustion chamber with maximized flexibility and best-in-class Dry Low Emission system (DLE 1.5) down to 9 ppm NOx in Xtend 9 ppm version

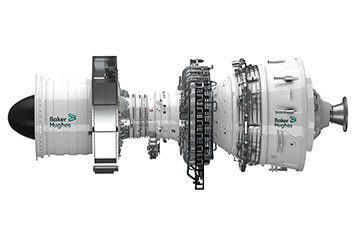

- Two options: low-speed power turbine (LM2500+) or high-speed power turbine (PGT25+) available for DLE High Power, DLE Xtend 9 ppm and SAC versions

Applications

- Onshore, off-shore

- Pipeline, gas storage

- Industrial, power generation, combined heat and power

Overview

Overview

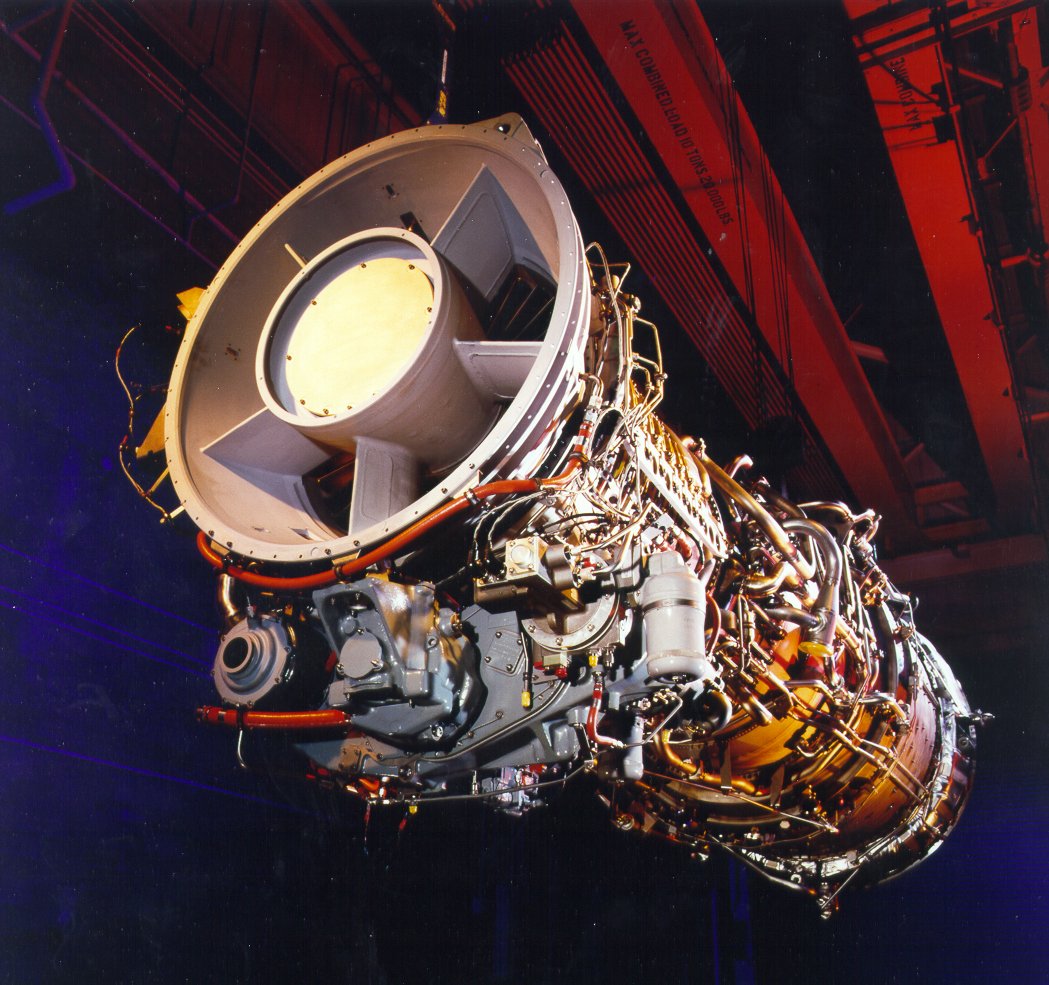

The PGT25+/LM2500+ turbine draws its high efficiency and light weight from our aeroderivative technologies proven in energy applications and aircraft engines, while its ruggedness is inherited from our frame gas turbine designs.

PGT25+ for mechanical drive

DLE Xtend 9 ppm

DLE High Power

SAC

Power (MW)

26.1

31.1

31.3

Efficiency (%)

39.6

40.5

40.6

NOx emissions (ppm)

9

15

25

Exhaust temperature (ºC)

480

500

500

Speed (rpm)

6,100

6,100

6,100

Boroscope inspection (hours)

8,000

8,000

8,000

Hot section inspection (hours)

32,000

25,000

25,000

Major inspection (hours)

64,000

50,000

50,000

Lean Pipeline package dimensions (m)

18.9x4

18.9x4

18.9x4

At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. Extended maintenance plan is available to increase plant availability; contact Baker Hughes to define your customized service contract needs. Package dimensions include driven equipment. 25 ppm NOx single annular combustor (SAC) configuration with water injection.

LM2500+ (50 Hz) for power generation

DLE

SAC

Power (MW shaft)

30.5

30.8

Efficiency (%)

37.3

37.4

NOx emissions (ppm)

15

25

Exhaust temperature (ºC)

528

528

Speed (rpm)

3,000

3,000

Boroscope inspection (hours)

8,000

8,000

Hot section inspection (hours)

25,000

25,000

Major inspection (hours)

50,000

50,000

Package dimensions (m)

16x3.4

16x3.4

At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. For the DLE Xtend 9 ppm version and for extended maintenance plans contact Baker Hughes to define your needs. Package dimensions include driven equipment. 25 ppm NOx single annular combustor (SAC) configuration with water injection.

LM2500+ (60 Hz) for power generation

DLE

SAC

Power (MW shaft)

31.2

31.4

Efficiency (%)

39

39.1

NOx emissions (ppm)

15

25

Exhaust temperature (ºC)

516

516

Speed (rpm)

3,600

3,600

Boroscope inspection (hours)

8,000

8,000

Hot section inspection (hours)

25,000

25,000

Major inspection (hours)

50,000

50,000

Package dimensions (m)

16x3.4

16x3.4

At ISO conditions with natural gas fuel, ambient temperature 15ºC, no inlet or exhaust losses, sea level, 60% relative humidity. For the DLE Xtend 9 ppm version and for extended maintenance plans contact Baker Hughes to define your needs. Package dimensions include driven equipment. 25 ppm NOx single annular combustor (SAC) configuration with water injection.

Well-known technology

The PGT25+/LM2500+ is a proven design based on LM2500 gas generator technology with more than 100 million industrial operating hours, and aircraft engine experience with over 350 million flight hours.

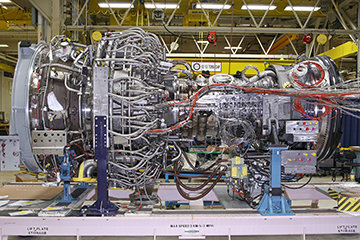

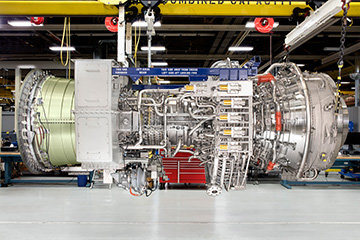

Ease of maintenance and high unit availability

The package is preassembled and tested in our facility to minimize on-site assembly time. The gas generator and low-pressure turbine can each be easily and quickly removed and replaced, and full engine replacement performed in just 48 hours. An optional extended maintenance plan is available—increasing boroscope interval by 2,000 hours, hot section inspection by 5,000, and major inspection by 10,000.

Enhanced fuel flexibility

The turbine can operate on a wide range of liquid and gas fuels while minimizing NOx emissions at 15 ppm, thanks to its DLE1.5 combustion system.

Product Resources