The success of your well ultimately depends on the effectiveness of your perforations—the conduit between the reservoir and your wellbore. Wireline-conveyed perforating services from Baker Hughes give you proven solutions to reduce the cost and complexity of perforating operations in your unconventional reservoirs, horizontal wellbores, and tight formations.

Draw on our 80 years of perforating experience and vast wireline expertise to solve your most demanding perforation challenges.

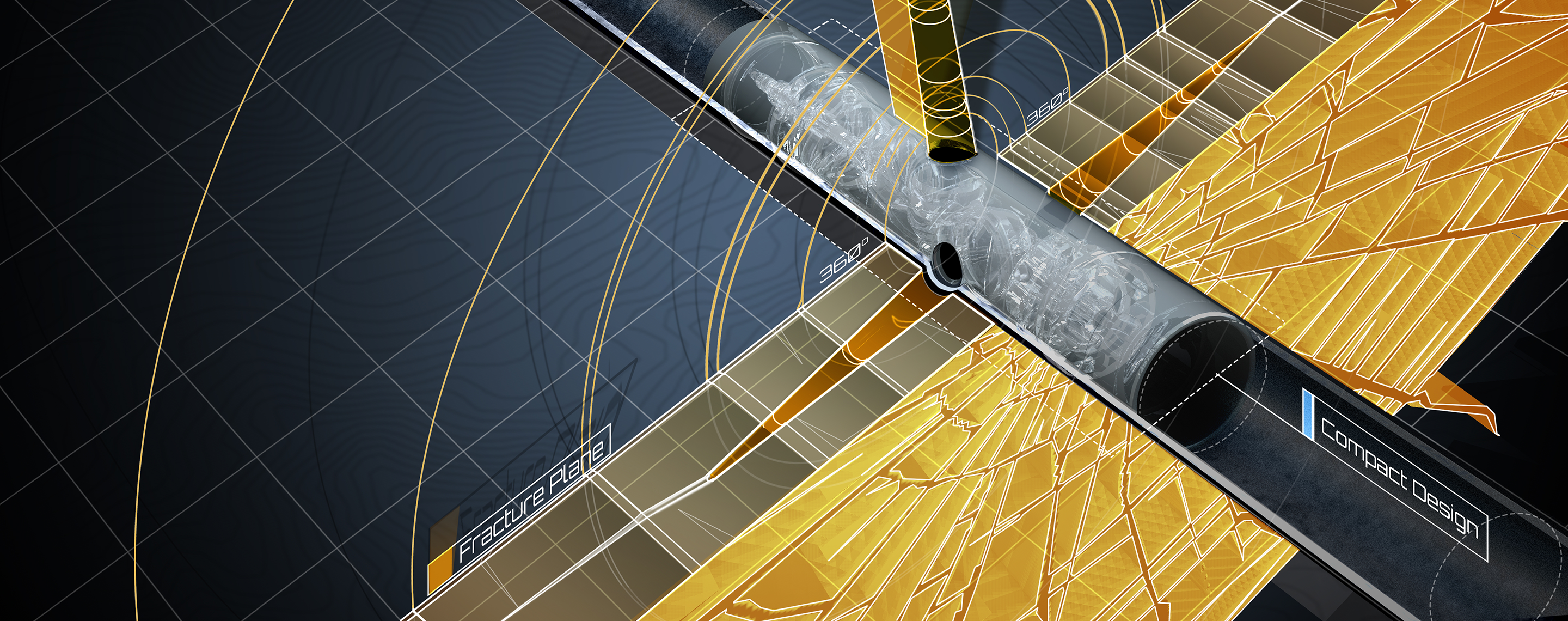

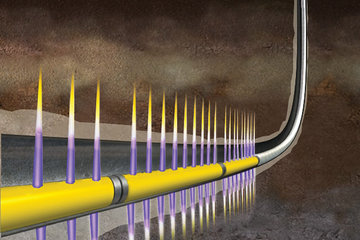

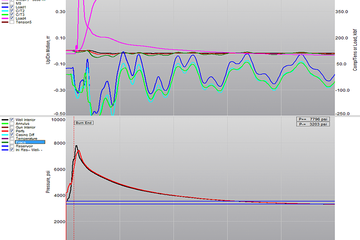

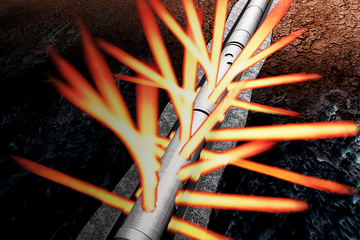

Maximize your reservoir contact and production potential. Enhance your fracture treatments with perforating gun systems that generate perforation patterns that improve proppant dispersion, placement, and penetration into the formation—thus increasing reservoir contact and improving reservoir drainage.

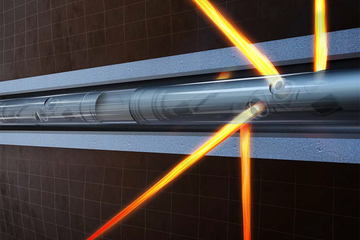

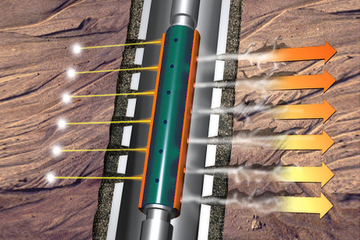

Perforate under pressure. Save time and money while perforating new sections of your producing well with live-well deployment systems that run guns on wireline under pressure, without the need for additional drilling, workover rigs, or killing the well.

Perforate long intervals in just one run. Reduce rig time and completion costs in your long-lateral perforation jobs with our gun systems and brakes that effectively perforate extended laterals in a single, underbalanced operation during both new completions and well interventions.

Deploy at lower cost and risk. Improve your operations at the rig site with wireline-deployed systems that offer a shorter gun length, fewer shaped charges, and simplified handling at the surface—all of which allow greater operational efficiency at reduced health, safety, and environmental (HSE) risks.

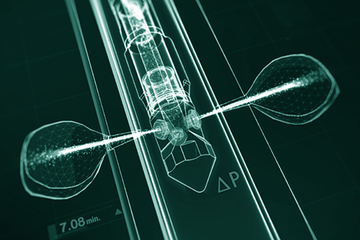

Optimize specific completion requirements. Choose from an array of shaped charges engineered to create greater connectivity, maximize penetration past damaged or invaded zones, and optimize reservoir drainage—reliably and economically.

Let’s work together to find the optimal wireline-conveyed perforating system to maximize production in even your most challenging well geometries.