Accurate reservoir analysis

Conventional coring services include acquisition and recovery to the surface of a continuous column of reservoir formation material. Baker Hughes manufactures core bits and uses special drillstrings with inner and outer barrels. You can rely on our high-quality core samples for accurate reservoir analysis while controlling core acquisition costs.

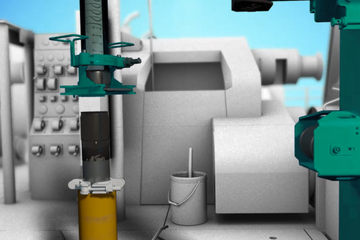

HT Series conventional coring systems

Our HT Series™ barrels address all your formations and coring applications, especially high-angle and extended-reach wells. The series’ stabilized sections, built-in 30-ft (9-m) lengths, connect for coring runs of more than 600 ft (183 m). Steel or aluminum inner barrels containerize the core and mitigate risk.

HydroLift unconsolidated coring system

The HydroLift™ system addresses unconsolidated or friable formations. A full-closure mechanism ensures core recovery. The system also suits fractured formations with jam potential, while a slick-entry feature helps prevent jams as the core enters the catcher.

CoreGard low-invasion coring system

The CoreGard™ low-invasion coring system protects against dynamic filtrate invasion. Special pilot shoes protect your core column, while face-discharge core bits force 60 to 85% of the coring fluid through ports.

JamBuster anti-jamming system

The JamBuster™ anti-jamming coring system enables coring after jamming occurs. Telescoping inner core barrel sleeves mitigate the effects of core jams, eliminating unscheduled trips out-of-hole and related nonproductive time. The system therefore significantly increases the amount of core cut per run in jamming prone formations.

Gel coring system

The CoreGel™ system uses a viscous, noninvasive gel to protect cores from drilling fluid invasion, which can alter the chemical and physical properties of the cores. The gel fully encapsulates the core downhole to prevent contact with the drilling fluid and supports the core during recovery, surface handling, and transportation.

Core bits

High-performance, premium core bits are compatible with our coring technology. Our Genesis™ and Talon™ PDC (polycrystalline diamond compact) bit technologies ensure stable performance. Many bits have the face-discharge technology and can be used in combination with the CoreGard low-invasion coring system. Our bit portfolio provides features adjusted to the needs of all your applications and formations.

LaserCut liner system

The LaserCut™ liner system containerizes core material during coring while enabling easy access to the core at the surface. The system offers enhanced safety features, rig floor core handling, and one-piece liners for splitting at the surface, enabling rapid core examination.

SOr sponge liner coring system

The SOr™ sponge liner coring system improves core sample quality to help you make a more informed field development decision while lowering data acquisition costs and nonproductive time.

CoreCare transportation

The CoreCare™ transportation equipment ensures that the quality of the core is maintained during the handling and transportation of the core from the field to the laboratory. The optional CoreCare tracking service provides a time-based record of any shocks and temperature changes during transportation, enabling feedback for continuous improvement during the transportation process.

GammaTrak continuous logging

The GammaTrak™ wellsite gamma logging unit is used to efficiently verify core recovery, confirm target intervals, evaluate lithology, and correlate offset well logs — right on the rig floor. The unit quickly generates a real-time continuous gamma versus depth log along the entire length of the core sample, which can be correlated to conventional wireline and measurement-while-drilling (MWD) logs.