Highlights

Highlights

Benefits

- As an original equipment manufacturer (OEM), we know our equipment in depth

- We provide a complete and reliable range of repair and upgrade services, along with unequalled knowledge and expertise

- Our footprint blends local speed with global domain competence integrated into a fullstream company

Features

- Full lifecycle services to optimize availability and reliability in mechanical drive, compression, and power generation

- We offer the most advanced technology and repair solutions, with services designed to meet particular needs

- Dedicated and specialized service engineering solutions

Applications

- Equipment upgrades for all onshore and offshore oil and gas and industrial applications

- Component life-extension management

- Full in-house test capabilities to guarantee best site availability

Overview

Unique product knowledge and repair expertise have been at the core of our global repair network since 1970. We perform repair activities on all our OEM components, leveraging our extensive engineering knowledge across product design and manufacturing, installation, operation and performance enhancement.

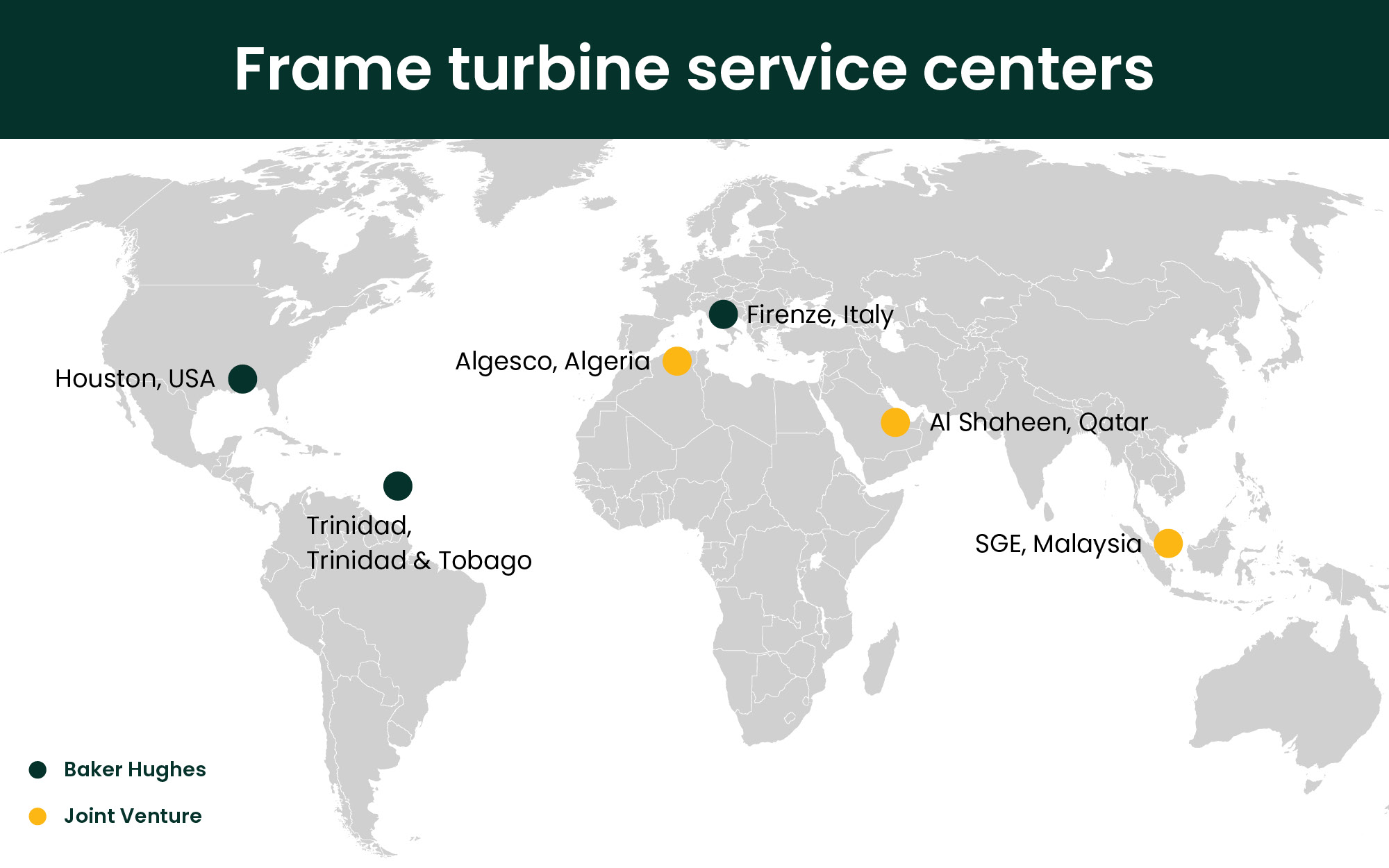

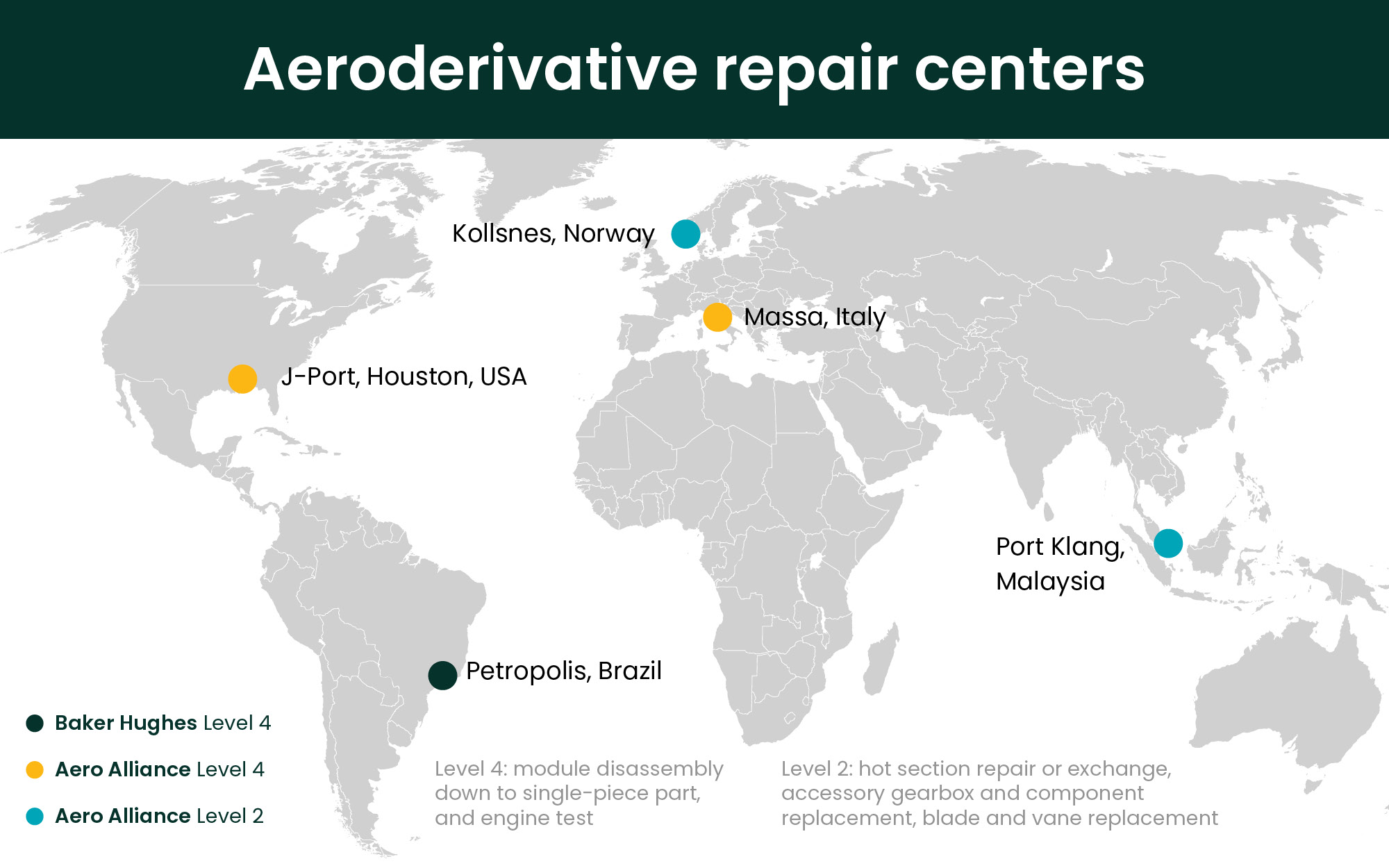

With repair shops strategically located around the world, we ensure efficient and effective service to onshore and offshore customers in any location—with standard and customized repairs to satisfy any requirement for machine performance, quality, and reliability. The strengths of our local resources and partner networks ensure reduced intervention time, including preliminary assessments at customer sites.

Service Centers

We service the entire range of Baker Hughes rotating equipment, including new edge technologies. Our service network uniquely blends local resources with global domain experience to deliver unmatched service speed and quality to customers worldwide. Our facilities use advanced repair processes including coating, welding, heat treatment, NDT—and employ some of the most experienced and skilled professionals around the world.

Technology

We have advanced in-house capabilities for corrosion, erosion, and high-temperature protection coatings, as well as stripping, HVOF, APS, and patented cold spray. Our advanced inspection technologies‚ including high-temperature super-alloys residual life assessment, reliably identify defects on all parts. We also have additive technologies such as brazing and metal build-up for high-temperature parts and surface reshaping.

Processes

Our local teams provide customized inspection of all turbomachinery components directly at customer sites. Our Rotor Life Management (RLM) program employs advanced engineering assessment to enable equipment operation beyond its original design life. Our Used Serviceable Machine (USM) program provides expertly refurbished replacement assets to reduce major inspection (MI) downtime, avoid production loss, and optimize costs.