Highlights

Highlights

Benefits

- Cost-effective option to maintain site configuration and decrease outage downtime for current and out-of-production gas turbines

- Faster equipment swap through OEM interchangeability study

- Create pool of spare components and modules at lower costs

Features

- OEM expertise, quality, and warranty through Baker Hughes TPS Repair Network

- Flexible configurations to fit customer site requirements with minimal package modifications

- Ready to serve, on-the-shelf refurbished equipment and components

Applications

- Major outages, modular replacements or repairs

- Site equipment upgrades and rejuvenation

- Multi-outage modular and components rotation

Overview

Overview

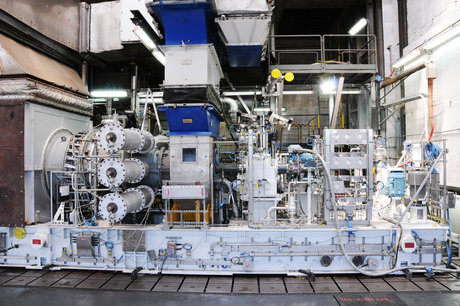

Baker Hughes's Certified Renewed Equipment options include a variety of gas turbine equipment, from components and rotors to full flange-to-flange modules. With more than 115 assets refurbished and running globally, our equipment provides cost-effective solutions to decrease total outage and overhaul cycle times, while ensuring availability of equipment based on current or out-of-production technology.

Our renewed products are backed by OEM warranties and can be purchased with advanced support from Baker Hughes's turbomachinery services, including interchangeability studies, installation, and consultative support.

Specifications

Low Pressure Cartridge HSPT

Standard, PIP, G4

Low Pressure Cartridge PGT25

46 and 72-hole configurations

Frame 3 gas turbine module

F, J, J-HT

Frame 5 single-shaft gas turbine module

L, LA, M, R, N, P, PA

Frame 5 double-shaft gas turbine module

B, C, C+, D

PGT10 gas turbine module

Single and double-shaft

PGT5 gas turbine module

B, D

Gas turbine components

Rotors, nozzles, buckets, statoric

Gas turbine rotors

Frame3, Frame5, PGT10, PGT5, HSPT