Orbit June 2022 Edition

Learn. Share. Experience.

Most organizations want to drive ongoing improvements to reliability, but the challenge for many is knowing where to focus their efforts for maximum impact. The reality is that a myriad of factors influence reliability. These range from the selection, procurement, storage, and installation of assets to how they are operated, monitored, and maintained, The Value of a Reliability Program Assessment.

In our 10th article for the Orbit 60 Series, we focus on Orbit 60 and enabled enhancements; we are very pleased with our new product. Similar to all of our major monitoring line products, 7200, 3300 & 3500, we are only able to introduce certain functionality initially, and then build on that foundation. Our first release, which has been successfully installed in multiple locations was what we call our API 670 release. Orbit 60 Series Update: New Features with Our Latest Release due this month.

In this edition, we also will share a success story that describes structural tests performed on the gas pipe and piping supporting system installed along a bridge. These tests were part of an investigation that was done as a preparation for the monitoring system installation. The objective was to obtain the information regarding the vibrational responses, the natural frequencies, and the related modal shapes, to optimize the distribution of permanent sensors. These sensors will form part of the condition monitoring system - to be installed in the immediate future - which will allow early detection of system degradation and overall prevent catastrophic failure, Gas Piping Condition Monitoring Deployment, a real life scenario.

Historically, frame vibration has been used as a safeguard measurement on reciprocating compressors to save assets from potential catastrophic failures. Until the late 1980s, seismic switches (aka earthquake triggers) were used to automatically trip machines in case vibration exceeded pre-defined setting. Due to the binary nature of switches, it was not an effective way of tracking the changes in vibration that could be attributed to developing issues in the machine. Hence, the industry started shifting towards transducers and transmitters to enable online continuous monitoring, Reciprocating Compressor Condition Monitoring.

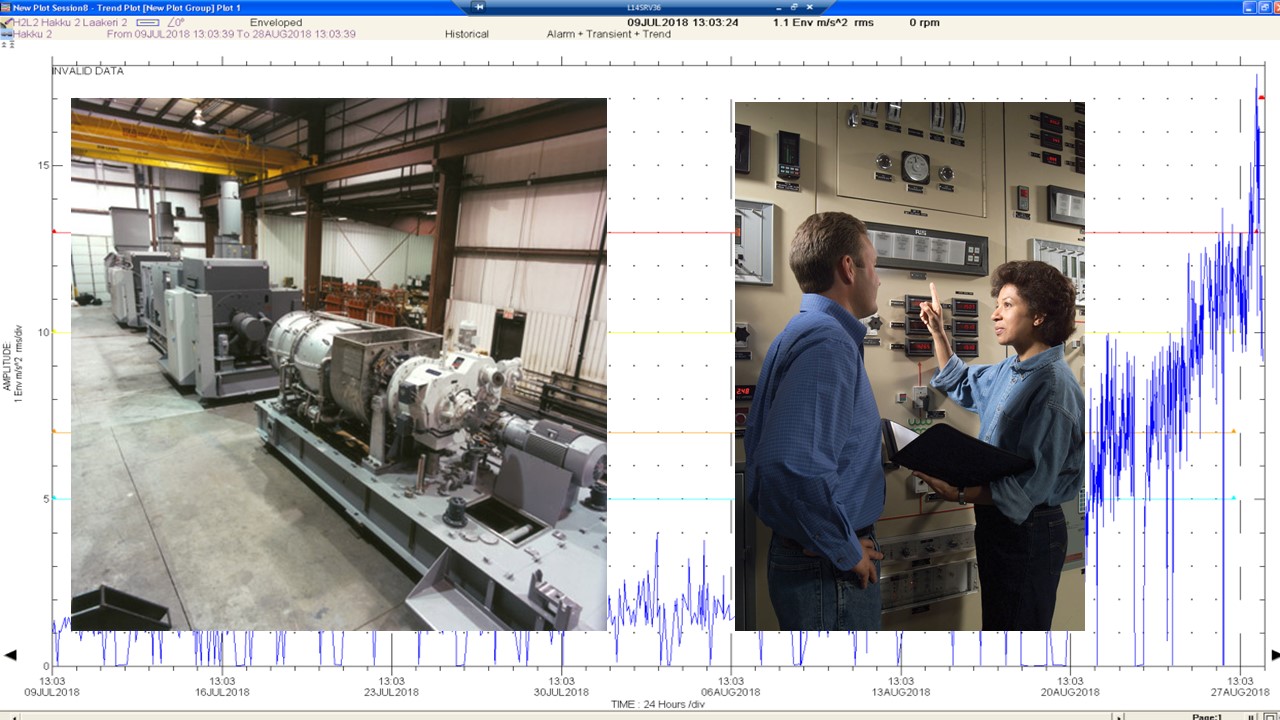

This article is about condition monitoring alarm setting, not about setting the protection alarms. Condition monitoring of rotating machinery is very much about detecting changes. Some changes are natural and acceptable, like changes due to the machine load or RPM, but most of the changes are making us wonder how long we can operate the machine safely. The most popular way to detect changes is to apply alarm levels to the vibration data that is collected. However some do it by manually browsing through all the data that has been collected and comparing the latest readings to the ones collected earlier. Surely both ways can lead to a good or bad end result, but in today industry where resources are limited, we should be leaning more towards the use of alarm functionalities, Condition Monitoring Alarm Levels.

Finally, a customer shares their real time story; S-Oil produces lube base oil, petro-chemical products, and operates crude oil refining facilities of 669,000 barrels a day in the Onsan Industrial Complex of Ulsan, Korea, which is the world's largest paraxylene (PX) production facility, and bunker-c cracking center of worldwide standard. In 2021, a Bently Nevada reciprocating compressor condition monitoring system, including on-line dynamic cylinder pressure, was implemented for this compressor to detect earlier indication of machine problems and provide better diagnostics capability, the Value of Cylinder Pressure Measurement for Reciprocating Compressor.