Overview

When managing your rotating machinery's overall health, the condition of your rolling element bearings and cylindrical roller bearings plays a critical role. A single bearing failure can cause machine shutdown, resulting in costly downtime and production loss.

At Bently Nevada, we offer a wide range of bearing condition monitoring tools, software, and equipment for early spherical roller bearing, deep groove ball bearing, thrust ball bearing, tapered roller bearing, needle roller bearing, cylindrical roller bearings, and rolling bearing fault detection and diagnosis.

From vibration sensors to data acquisition tools and diagnostic software, we have the solutions you need to keep your plant running efficiently and effectively. Properly designed and carefully lubricated bearing arrangements have a virtually infinite life. However, given enough time all types of bearings will eventually fail through a fatigue mechanism that can be greatly accelerated by poor installation, misalignment, inappropriate axial loads or radial loads, improper lubrication, or contamination.

Explore Bently Nevada's full range of asset performance management and monitoring solutions for protecting your plant-wide machinery and preventing unplanned downtime.

Product Portfolio

Rolling element bearings depend on an extremely thin layer of lubricant to keep rolling element/race contact to a minimum. The rolling elements actually skid to a degree, and the lubricant forms a type of elastohydrodynamic wedge that keeps the elements separated. The separation of elements is on the order of a few times the typical surface roughness, less than a micron (or a few micro inches).

The lubricating fluid also serves the purpose of removing the heat that is generated by shearing in this very small gap between elements and races. If the lubrication supply is insufficient, then metal-to-metal contact will occur, creating wear and possible smearing of races. The lubricant must be clean and of the proper type for the load and operating temperature. Rolling element bearings can survive for long periods of time quite well with relatively small amounts of lubricant. Excessive lubrication can be harmful by causing high temperatures from the lubricant shearing stresses and can actually lead to bearing failure.

Some signs of a bearing lubrication issue include:

- Discoloration

- Scoring and Peeling

- Roller end/Bearing metal temperature

- Bearing lockup

Cleanliness of lubricant is vital to long bearing life. If dirt particles get into the bearing either directly or through the oil system, then the particles can become trapped between the rolling element and the race. If the particle has sufficient hardness, then the extreme stress produced at the particle contact will cause local plastic deformation of the race and/or element material. This will produce a permanent pit that will act as a potential crack nucleation site. Even micron-sized debris that becomes trapped between a rolling element and a race can cause local plastic yielding and the formation of a small pit on either or both surfaces. The relatively small radius of the pit boundary acts as a stress concentration factor and greatly increases the likelihood of initiation of a fatigue crack. It is also possible for a large particle to jam in such a way as to reduce element rolling action and increase sliding motion. During sliding motion, the dirt particle can act like a plow, creating a permanent groove in the race surface.

Some signs of a bearing oil contamination issue include:

- Bearing wear

- Bearing pitting

- Bruising

Many bearings are doomed during installation. Bearings must be handled carefully and installed in accordance with the manufacturer’s specifications. If interference fits are used on the bearing rings, care must be taken to avoid deformation or cocking of the outer rings during installation. Cocked or misaligned bearing rings will produce abnormal loads in the bearing. Incorrect fits can also subject the bearing to abnormal loads. Although this may seem obvious, bearings should never be pressed on in such a way that the press load is delivered across the rolling elements. The high press loads can cause the balls to permanently dimple (brinelling) the raceway.

Bearing misalignment often results from the improper fit of housings and shafts. Common issues include:

- Bent shafts

- Out-of-square shaft shoulders

- Out-of-square spacers

- Out-of-square clamping nuts

- Improper installation & loose fits

If the designer fails to consider all the possible radial loads and axial loads that can occur in service, the bearing selected for the application could be incorrect. If the service loads exceed the design intention, then the bearing will fail prematurely. The designer needs to be aware of the static and dynamic loading that may be present in service.

On the other end of the load spectrum is the situation where the bearing is very lightly loaded. In this condition, the roller skids rather than rolls, which is also not desired. It is also possible that a wrong bearing was installed during assembly or repair.

Bearing life is very sensitive to loading. Bearing loads can be classified into static loads, which have constant magnitude and direction, and dynamic loads, which can vary in both magnitude and direction. To properly size a bearing at the design stage, a machine designer must consider both types of loading and their influence on the predicted life of the bearing. If during service the loads in a machine deviate significantly from design tolerances, bearing life will be affected.

Misalignment is an important source of excessive static load. Properly designed and sized couplings will accommodate misalignment to some degree, but if misalignment exceeds the capability of the coupling, then excessive loads may appear at the bearing. Another important source of static load is a belt drive.

Dynamic loads are introduced by many rotor malfunctions but may also result from the work the machine is doing. Unbalance, rub, or aerodynamic or fluid-induced instability can produce dynamic loads that exceed design limits and reduce rolling element bearing life. Also, coupling malfunctions may introduce excessive static and dynamic loads.

Brinelling is a form of non-rotating load damage. When a rotor is stopped, the rolling elements in bearings remain in one position. If the machine is subjected to a shock load, the elements (especially balls) can plastically deform the races, creating a permanent set of pits. This has happened to new machines being shipped by rail or truck. The machines arrive at the plant only to find that the bearings are ruined. To prevent this kind of damage, vulnerable machinery is usually rotated on turning gear during shipment.

It is normal that a spare (standby) machine is exposed to some level of vibration while not operating. Its static load will press lubrication away from the bearing load zone, allowing metal-to-metal contact between elements and races. If the vibration is high enough, when the primary machine fails after a long period of service, the spare machine’s bearings may fail due to brinelling damage shortly after it is online and before the primary machine is repaired. A preventative measure is to run the backup machine periodically.

Improper electrical grounding can cause a current to flow through rolling element bearings. If arcing occurs, small quantities of bearing material are vaporized in the small, high temperature electric arc. This vaporization effectively removes material from the rolling element or bearing race or both. The resulting pit acts as a stress concentrator that is capable of nucleating a fatigue crack, leading to eventual failure. The damage caused by the electrical arc is similar to electrical discharge machining (EDM), and takes place on motors with a variable frequency drive. On rare cases this can also be due to buildup of static charge from the process fluids and materials.

Assuming that a bearing is properly loaded, clean, and supplied with a correct amount of clean lubricant of the proper type; failure of a typical rolling element bearing is still inevitable because of fatigue. Rolling element-bearing loading differs substantially from the type of loading that is found in other engineering structures where an endurance limit can be used to guarantee freedom from fatigue failure. Unfortunately, no such endurance limit exists for rolling element bearings, and fatigue failure of these bearings will eventually occur.

As the bearing evolves toward fatigue failure, spalling occurs on the outer race, inner race, or elements. As rolling elements encounter spall pits (or as damaged elements rotate), the impact/response vibration tends to repeat at characteristic frequencies, called bearing defect frequencies, often referred as fault frequencies. Each bearing has a set of defect frequencies associated with inner race, outer race, element, and cage defects that are determined by its particular geometry and operating speeds.

Bearing Wear Monitoring - The Bently Approach

In an ideal scenario, machines with rolling element bearings would be monitored in the same way as critical journal bearing machines (vibration transducers at each bearing, bearing temperature, Keyphasor† sensor, online monitor). However, it can be economically difficult to justify that level of monitoring.

The best method for monitoring bearing temperature, wear and overall condition is through online monitoring - using either a permanently installed, continuous or scanning systems. With an online system, a proper transducer suite is needed to detect when a machine is having a problem.

In the absence of an online monitoring system, a portable data collector (PDC) is the next best approach. An important part of establishing a PDC route is defining how often the data is taken. The more often the data is collected, the more likely an early bearing failure detection will be made. But as a consequence, the cost of the condition monitoring will be higher due to more frequent data collection and analysis. The route creation and timing depend on the machine operating hours, running speed, load, process and environmental conditions, and so on.

For further information regarding roller element bearing monitoring, please contact a Bently Nevada application and solution architect or machinery diagnostic services engineer to assist you with recommendations.

Case Studies

Orbit 60 Series is Bently Nevada’s next generation of machinery protection and condition monitoring designed to be the most advanced system for all your critical machinery assets, as well as your plant-wide assets, across a wide range of industrial applications. Orbit 60 Series is built on a fully distributable architecture that allows you to monitor all your assets regardless of complexity or location and is intrinsically cyber secure.

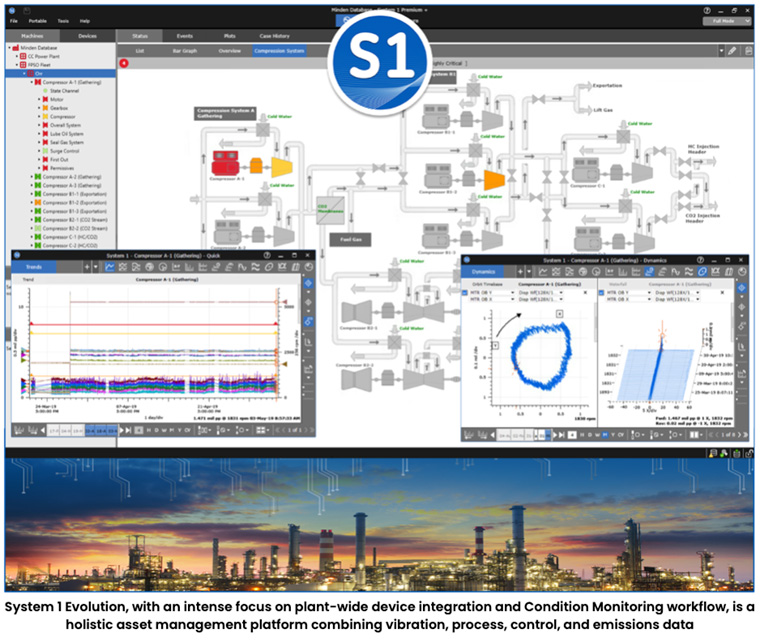

Our System 1† Condition Monitoring software has been designed as an all-in-one answer to even your most difficult machine asset management and health monitoring challenges. Building on the strategic pillars of Connectivity, Analytics, and Visualization the System 1 platform provides the plant-wide critical asset monitoring data and analytics solutions you need to keep your plant running smoothly and avoid unwanted downtime.

System 1’s connected platform gathers and stores important machine health data across your entire enterprise in one central location, for real-time analysis, diagnosis and preventative condition-based maintenance planning. Make data-informed decisions and achieve true operational intelligence with System 1.

When you need real-time vibration and temperature monitoring combined with rapid, simple deployment of multiple sensors in a wireless network, encrypted data transmission, long battery life, and the ability to work in hazardous environments, Ranger Pro is your answer.