Extend machine runtime and eliminate reactive firefighting

Are you struggling with unnecessary downtime that is cutting into your machine runtime? Is your reliability team being overwhelmed with threshold-based alarm floods? Facing higher than usual spare part inventory costs because you can’t plan your maintenance weeks in advance?

Machine Health analyzes millions of condition monitoring sensor outputs 24/7—alerting your team well in advance of failure, diagnosing root causes, and prescribing fixes, so your team does not have to worry about emergency downtime on a weekend, overnighting spare parts, or being constantly overwhelmed with alarm fatigue.

Bently Nevada and Augury joined forces to combine the 60+ years of BN’s leadership in energy and heavy industry with Augury’s leadership in AI-driven machine health in manufacturing. Together we deliver the world’s most effective and scalable Machinery Health coverage of your plantwide assets.

A range of compatible sensors capture and transmit data continuously into pre-trained, purpose-built AI models which makes it possible to deploy faster and detect failures early on. This results in short Time-to-Value and higher ROI vs general-purpose AI which can take months to deploy and years to deliver value.

In primo piano

Machine Health is trained on tens of thousands of machines and uses vibration trend data to detect early signs of machine failure, diagnose root cases, and prescribe fixes for the maintenance team.

In primo piano

Machine Health is a "hybrid intelligence" solution that is paired with expert support that helps users plan and prioritize maintenance activities.

In primo piano

Users collaborate with Machine Health's platform and act on guidance to help improve the health and performance of their assets.

In primo piano

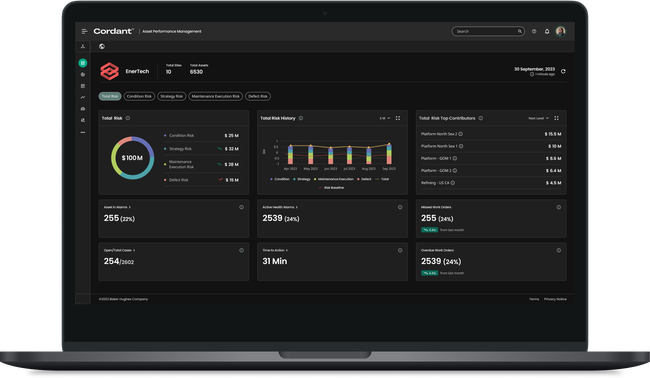

Cordant Asset Performance Management combines asset health, strategy, and defect elimination in one fully integrated solution

Cordant Machine Health is part of our Cordant solutions