Industrial equipment maintenance plays an integral role in the daily operation of any multi-functional facility. At the highest level, industrial equipment maintenance is a strategy that involves monitoring, inspecting and correcting any issues that can occur with plantwide equipment or systems.

As industrial systems evolve, the implantation of condition monitoring and its required technology (i.e. sensors reporting real-time equipment status and output data) is crucial. With a proper industrial equipment maintenance strategy in place, you can increase your ROI by alleviating unplanned production interruptions caused by system failures.

There are steadfast approaches to developing an effective plantwide maintenance plan. Let's explore these options further and discover how you can utilize these maintenance methods to achieve optimum equipment performance.

Predetermined industrial equipment maintenance is based upon the suggestion of the original equipment manufacturer (OEM). Typically, this type of maintenance is time or calendar-based and relies heavily on a predetermined "wear and tear" threshold. A common example of predictive maintenance would be changing your car's oil every 3,000 miles.

Pros:

- Suggested maintenance and applicable replacement time frames are based on historical data and statistics.

- You can easily automate your scheduled maintenance or replacements so any potential production interruptions can be planned well in advance.

Cons:

- Supplied OEM data is not a "catch-all." You can potentially risk equipment failures prior to the OEM's suggested replacement/maintenance date.

- Predetermined maintenance may also be costly if you prematurely replace functioning equipment.

Condition-based industrial equipment monitoring is monitoring the current condition of the equipment to determine a potential risk of failure. This type of maintenance is a predictive maintenance strategy and only occurs when data indicates a performance decline. A common example of condition-based monitoring would be a technician using a sensor to monitor an industrial oven that is not heating up to its intended temperature or taking longer than expected to do so.

Pros:

- This method is cost-effective since maintenance is only performed on an as-needed basis.

- Prevents companies from initiating unnecessary maintenance.

Cons:

- Sensors used can be costly upfront.

- Sensors themselves must be monitored to ensure they are operating properly.

Corrective industrial equipment maintenance typically occurs when an issue has been during the inspection of another piece of equipment. An example of this type of maintenance would be a plumber noticing and replacing a corroded pipe while on a call to remove a blockage.

Pros:

- This is a cost effective and streamlined process as it does not require additional maintenance strategies or inspections.

- Great for assets that are less critical.

Cons:

- This type of maintenance can be unpredictable as issues are only addressed when noticed.

- Unexpected maintenance on a piece of equipment can cause unplanned production interruptions

Preventive industrial machine maintenance is the use of scheduled maintenance inspections that are carried out at multiple times each year. A common example would be regularly lubricating the hinges on an industrial oven.

Pros:

- Decrease in equipment downtime or production interruptions

- Life of asset is longer as equipment is regularly inspected and maintained.

Cons:

- Increased cost of time and money to keep equipment maintained

- Potential overuse of resources if a piece of equipment is constantly being monitored when no failure risk is present.

Predictive maintenance is a form of condition-based maintenance where equipment or operating systems are monitored using attached sensor devices. These sensor devices constantly record data that maintenance technicians use to monitor performance.

Pros:

- An equipment shutdown is typically not required to monitor, so production can continue uninterrupted.

- Constant monitoring will ultimately protect assets from failure.

Cons:

- Condition monitoring equipment can be costly upfront to install.

- It may cost more time and money to train employees to use condition-based monitoring technology correctly.

With slimmer margins and higher cost of complex machinery and processes, industrial equipment maintenance can be a cumbersome undertaking. Ever-evolving regulatory standards require additional resources to keep your systems compliant. In addition, cyber security has increasingly become a threat when using industrial maintenance technology like sensors and other required components to collect real-time performance data. Though it is important to be aware of the modern pressures that accompany industrial maintenance when developing a plan, it is equally important to understand its necessity.

Modern Solutions for Industrial Maintenance - the Bently Way

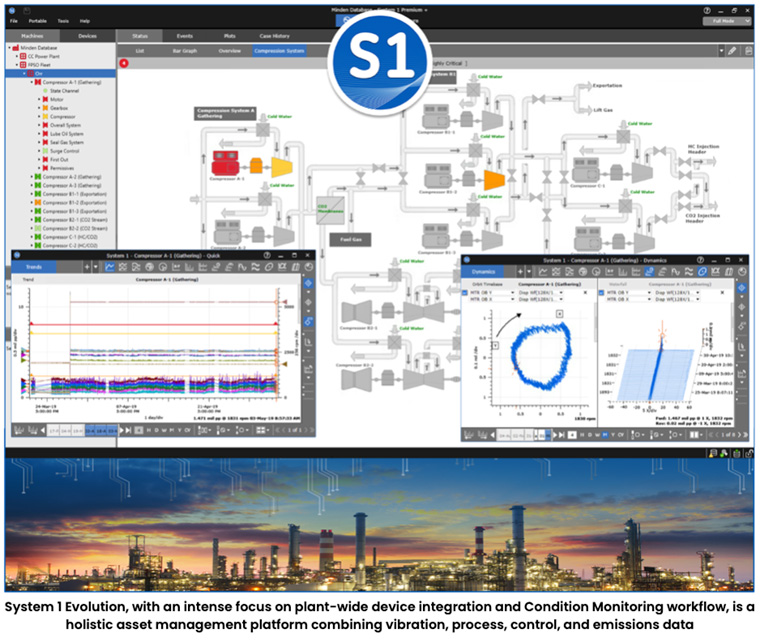

The advancement of technology has introduced highly advanced and secure systems, including wireless sensor technology, portable data collection devices, distributed monitoring systems, condition monitoring software and more. We offer several resources and technologies that make it easier and more cost-efficient to develop a well-designed maintenance plan.

The first step in any industrial equipment maintenance plan is to assess both your current operational outputs and future operational goals. Bently Nevada represents the world’s best industrial equipment monitoring products, services, and expertise.

Contact Our Industrial Plant Maintenance Experts For Help With A Customized Plan.

The Orbit 60 Series is a highly advanced wireless condition monitoring system designed to monitor your critical machinery and plantwide assets in any location, from any location. This system allows you to develop all-encompassing and proactive maintenance and fleet management programs, allowing you to maximize productivity and reduce operational costs.

Condition Monitoring: Need or Luxury? Discover how failure patterns and industry statistics remain a driving force behind the need for condition monitoring and predictive maintenance strategies.

Nine Steps to Achieve Plantwide Condition Monitoring: Learn how to successfully implement a plantwide industrial equipment maintenance strategy through asset prioritization, the use of effective technology and appropriate condition monitoring.