Machinery Monitoring Systems

Bently Nevada offers condition monitoring systems for plant-wide machine monitoring and predictive maintenance.

Why use machine condition monitoring?

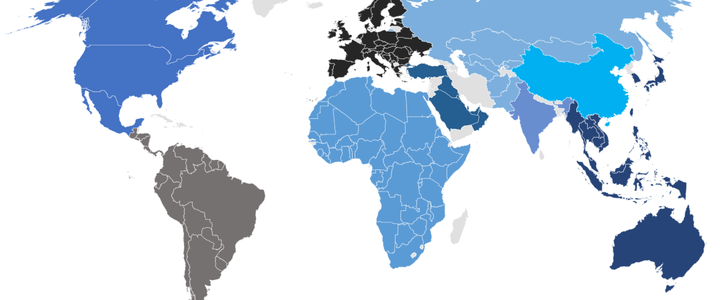

A streamlined equipment monitoring and machine condition monitoring system, allied with a predictive maintenance program, plays a vital role in the uptime of your machinery and profitability of your business. At Bently Nevada†, our history in the asset remote monitoring and condition monitoring system field is unparalleled. With over 50 years’ experience, we offer a cost-effective and comprehensive line of equipment monitoring and machine monitoring systems and asset protection services. No matter what your industry, you can trust Bently Nevada to optimize machine condition and operational efficiency.

Benefits of Condition Monitoring Systems

Bently Nevada’s advanced Machinery Monitoring Systems provide the following benefits:

Bently Nevada’s advanced machinery remote monitoring systems provide the following benefits:

- Timely and relevant real-time data acquisition and data collection

- Advanced root cause analysis and visualizations

- Accurate machine health diagnosis

- Early equipment failure detection

- Predictive maintenance planning and maintenance scheduling

- Extended machine life

- Reduced maintenance costs and downtime

- Maximized production and uptime

- Comprehensive plant-wide asset management

- True operational intelligence

Bently Nevada's online condition monitoring systems allow you to perform long-term monitoring of your assets' health, enabling planning for timely & cost-effective intervention, before faults occur. Bently Nevada offers a comprehensive suite of condition monitoring hardware paired with the industry's most innovative condition monitoring software, System 1.

Trendmaster - Continuous Vibration Monitoring System

Ranger Pro - Wireless Condition Monitoring Sensor System

SCOUT - Portable Vibration Analyzers & Data Collectors

vbOnline Pro - Gear Train & Roller Bearing Vibration Monitoring

Bently Nevada's Ranger Pro offers a wireless vibration sensor and condition monitoring system that allows users to collect exceptional condition monitoring data from hard-to-reach machines or hazardous areas, without the need for expensive field wiring. The data quality is so good that diagnosis can generally be made directly, without the need for portable devices to acquire additional data.

Ranger Pro - Wireless Condition Monitoring Sensor System (with Triaxial Sensors)

Protect your critical machine assets with Bently Nevada's line of online machinery protection systems. Our systems continually monitor the vibration levels of your critical assets, alerting you or even shutting down equipment if predetermined levels are exceeded. These systems go well beyond essential protection function, allowing for long-term asset health monitoring and advanced maintenance planning for timely & cost-effective intervention before faults occur.

Distributed systems are designed to be mounted close to the machine they are monitoring thereby reducing costly field wiring. They then use networks to bring data in from multiple devices for central monitoring. The comprehensive Bently Nevada range of distributed condition monitoring systems covers the spectrum from high-performance protection systems to cost-effective wireless condition monitoring solutions.

See all of our Distributed Machine Condition Monitoring and Protection Systems

Featured Solutions

vbOnline Pro - Gear Train & Bearing Vibration Monitoring Device

Trendmaster Pro - Online Vibration Monitoring System for Medium Criticality Machinery

1900/65A - Equipment Monitoring System

2300 - 2-Channel Vibration Monitor

Orbit 60 - Advanced Machine Condition Monitoring and Protection System

Our extensive family of portable data collectors and analyzers allow you to take our powerful diagnostic capabilities to all assets in your plant. Their advanced processing typically allows existing faults to be diagnosed quickly, or even detected months before intervention is required. And all this at a cost-per-asset that no other technology can compete with.

Learn how our portable vibration monitoring systems and equipment give you more options for asset condition monitoring.

SCOUT: Portable Vibration Analyzer

These are centralized systems, in which sensor wiring is routed back to a modular monitoring system mounted in a control room or cabinet. Bently Nevada has two separate choices in our rack monitoring system types, the industry-proven and tested 3500, and the soon-to-be-released Orbit 60 - the future of machinery monitoring.

3500 - Machinery Protection System

Orbit 60 - Next Generation Rack-Based or Distributed Online Condition Monitoring & Protection System

Read Our Latest Condition Monitoring Application Stories