Condition Monitoring for the Petrochemical Industry

Industry challenges

As global demand for petrochemical products continues to grow, new challenges to your business arise. Petrochemical product producers face constant fluctuations in feedstock prices, ever tougher regulatory and safety requirements as well as an aging workforce leaving the industry and who take with them a wealth of knowledge around your processes and machinery. But while all these changes certainly are challenging to your business, the best of today's machinery condition monitoring platforms make success in tough environments like yours possible.

Bently Nevada has been synonymous with machinery protection and condition monitoring for over 60 years in the petrochemical industry. Our advanced, high-quality monitoring solutions optimize plant safety, uptime and efficiency. Bently Nevada hardware, software and service solutions can be applied to all assets throughout the facility and communicate under a common condition monitoring and diagnostic platform.

With the help of Bently Nevada, you can turn today's production challenges into tomorrow's business success.

Closing the gap between your reliability “goals” and what you are actually obtaining from your current efforts typically involves three key impact areas:

Processes: Our comprehensive services help customers assess their goals, identify the reliability gaps in their current operations, and then implement the appropriate corrective actions.

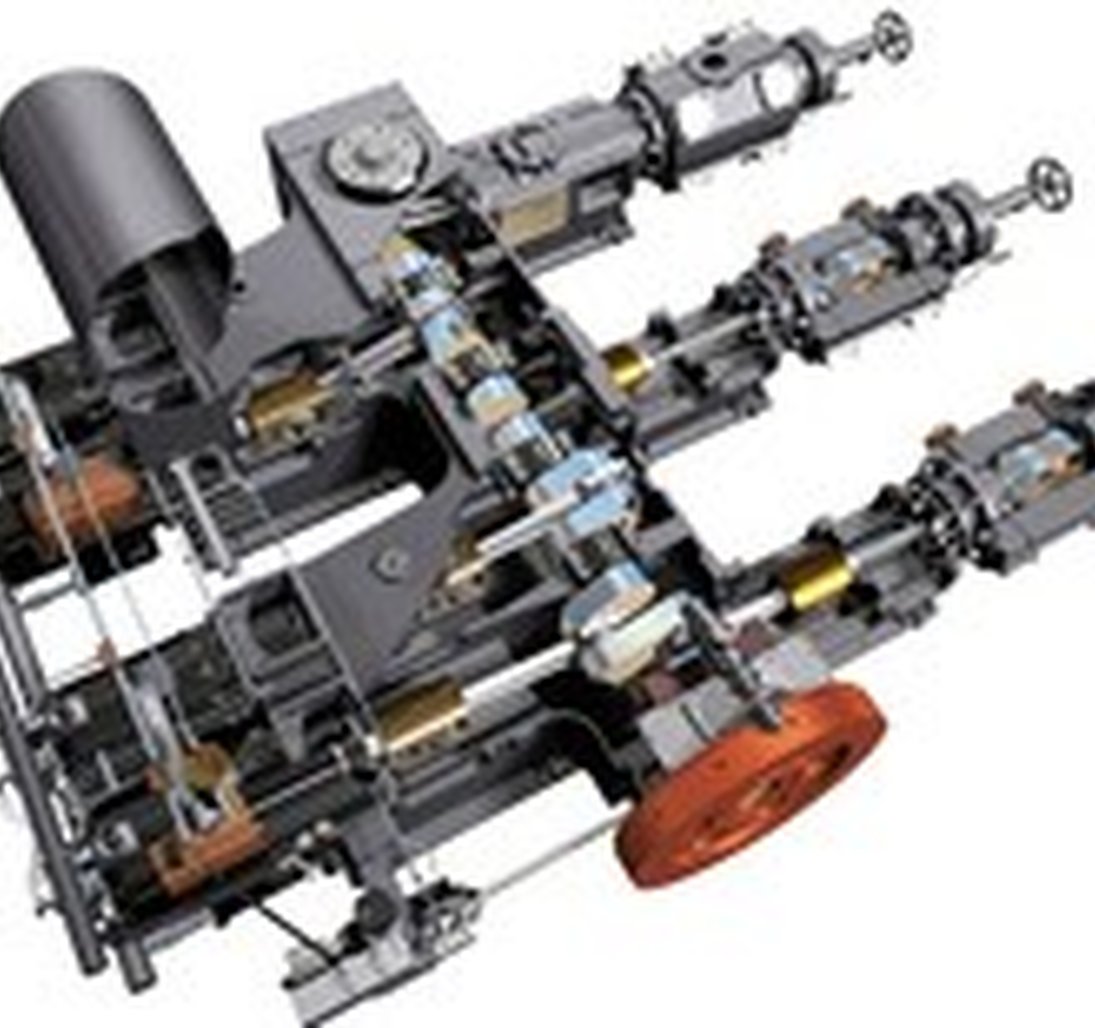

Tools: The Bently Nevada product line is world-renowned for unsurpassed quality in machinery condition monitoring. Everything needed to address the assets in a petrochemical facility is available, from sensors to continuous monitoring systems to wireless sensor systems to portable data collectors and analyzers. And, it’s all brought together in a unified platform for asset condition monitoring and diagnostics—Bently Nevada’s System 1† software. We also assist customers in integrating and using their already installed tools, such as computerized maintenance management systems (CMMS) and reliability software.

People: Reliability is about more than just technologies and processes. Even with the most sophisticated tools and effective strategies, companies can fail to reach their reliability goals unless they are able to successfully change the way they work. Reliability is a company-wide effort that touches operations, maintenance, planning and scheduling, purchasing, management, and engineering. Bently Nevada is able to help customers change the way they work by addressing the organizational culture issues that keep companies trapped in ineffective processes, helping them transform their plant operations and reach new heights of process quality.

Because Bently Nevada is able to fully address each one of these, we are able to solve the whole problem—not just bits and pieces.