Condition Monitoring for Discrete Manufacturing

Industry Challenges

- ~966 PB of Data

- Reduce Cycle Time of Product to Consumers

- Reduce Costs and Improve Safety

- Ensure Seamless Process and Asset Reliability in the Face of a Predicted 50% loss of Experienced Workers in the Next 5-10 Years

Discrete manufacturers face many unique challenges. At ~ 966 Petabytes (PB), you generate more stored data than any other industry. With all that data comes both opportunities and hurdles to overcome as you try to shorten product development times while reducing costs. The good news is that your data also brings with it the potential to improve your already lean manufacturing processes, and improve asset reliability for reduced machine driven downtime.

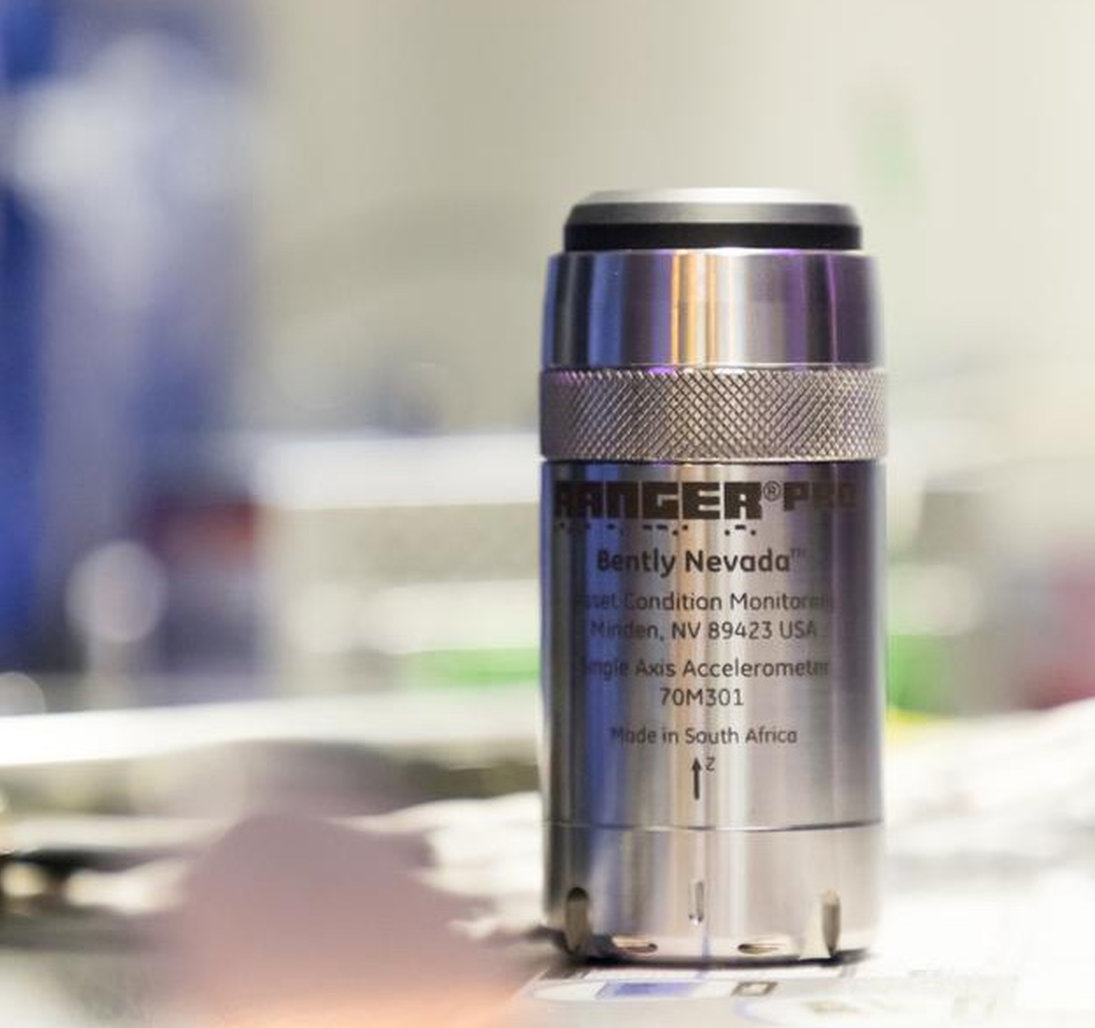

The machine data experts at Bently Nevada can tailor a plant-wide condition monitoring solution to help you reduce costs while maintaining the highest possible safety and environmental standards. We have been doing just that for customers in nearly every industry for more than 60 years.

It isn't a stretch to say Bently Nevada wrote the book on machinery protection and condition monitoring because we literally did!

Closing the gap between your reliability “goals” and what you are actually obtaining from your current efforts typically involves three key impact areas:

Processes: Our comprehensive services help customers assess their goals, identify the reliability gaps in their current operations, and then implement the appropriate corrective actions.

Tools: Our Bently Nevada product line is world-renowned for unsurpassed quality in machinery condition monitoring. Everything needed to address the assets in water and wastewater treatment plants is available, from sensors to continuous monitoring systems to wireless sensor systems to portable data collectors and analyzers. And, it’s all brought together in a unified platform for asset condition monitoring and diagnostics—Bently Nevada’s System 1 software. We also assist customers in integrating and using their already installed tools, such as computerized maintenance management systems (CMMS) and reliability software.

People: Reliability is about more than just technologies and processes. Even with the most sophisticated tools and effective strategies, companies can fail to reach their reliability goals unless they are able to successfully change the way they work. Reliability is a company-wide effort that touches operations, maintenance, planning and scheduling, purchasing, management, and engineering. Bently Nevada is able to help customers change the way they work by addressing the organizational culture issues that keep companies mired in ineffective processes, helping them transform their plant operations and reach new heights of process quality.

Because Bently Nevada is able to fully address each one of these, we are able to solve the whole problem—not just bits and pieces.